The Navy Department Library

History of the Bureau of Engineering Navy Department During the World War

Published under the direction of The Hon. Edwin Denby, Secretary of the Navy

PDF Version [18.1MB]

NAVY DEPARTMENT

OFFICE OF NAVAL RECORDS AND LIBRARY

HISTORICAL SECTION

_____

Publication Number 5

HISTORY

OF

THE BUREAU OF ENGINEERING NAVY DEPARTMENT

DURING THE WORLD WAR

_____

Published under the direction of

The Hon. EDWIN DENBY, Secretary of the Navy

WASHINGTON

GOVERNMENT PRINTING OFFICE

1922

_____

ADDITIONAL COPIES

OF THIS PUBLICATION MAY BE PROCURED FROM

THE SUPERINTENDENT OF DOCUMENTS

GOVERNMENT PRINTING OFFICE

WASHINGTON, D. C.

AT

60 CENTS PER COPY

_____

INTRODUCTION.

This description of the operations of the Bureau of Engineering (formerly Bureau of Steam Engineering) during the World War was prepared at the request of the Historical Section by Rear Admiral Robert S. Griffin, Engineer in Chief, U. S. Navy, Chief of Bureau, the distinguished officer on whom rested the responsibility for the varied and extensive duties and activities of the Bureau and its branches, so ably and efficiently performed.

W. D. MacDougall,

Captain, U S. Navy, Officer in Charge,

Office of Naval Records and Library, and Historical Section.

July 20, 1921.

--III--

[BLANK]

--IV--

PREFACE.

_____

In preparing this narrative of the operations of the Bureau during the war, I have been embarrassed on account of the fact that most of it was written so long after the events recorded—when the officers intimately associated with the work had either been ordered to sea duty or placed on inactive duty—that it has been almost impossible to give adequate space to many matters that deserve recognition. In some cases the records of important undertakings were so condensed, on account of war conditions, as to give all too brief mention of events that are deserving of extended notice. However, the entire story is submitted in the belief that the facts recorded have in them sufficient merit to be of general interest to all officers of the Navy, as well as to engineers either directly or remotely interested in the activities of that Bureau of the Navy Department which is responsible for the efficient operation of the motive power of our ships.

To Commander William L. Cathcart. U. S. Naval Reserve Force, I am under special obligation for assistance in preparing and in editing the manuscript.

R. S. Griffin,

Engineer in Chief, U. S. Navy,

Chief of Bureau.

May 8, 1921.

--V--

ACTIVITIES OF THE BUREAU OF STEAM ENGINEERING DURING THE WORLD WAR.

In order that the scope of the work performed by the Bureau of Steam Engineering1 may be clearly understood, there is submitted below a brief summary of its functions during the war.

The Navy Regulations state in broad terms that the duties of the Bureau comprise, amongst others, “all that relates to designing, building, fitting out, and repairing machinery used for the propulsion of naval ships,” the word “ships” including all floating craft of whatever description. The Bureau’s field is, therefore, largely that of dynamical engineering, covering the design, construction, maintenance, and repair of all steam and internal combustion engines used for propelling vessels of the Navy, as well as the electric motors and generators used in the case of “electric drive ” ships, and the storage batteries and electric motors for submarines. This includes not only the main engines and boilers but also all the auxiliaries and accessories necessary for the successful operation of the engines and for their maintenance in efficient condition.

The electrical engineering work of the Bureau comprises a great variety of duties besides those connected with the propulsion of ships. These duties are defined by regulation as “the entire system of interior communications * * * interior and exterior signal communications (except range finders and battle order transmitters and indicators), and of all electrical appliances of whatsoever nature on board naval vessels, except motors and their controlling apparatus used to operate the machinery belonging to other bureaus.” This means that the Bureau supplies the electric generators, switchboards and wiring, the call bells and buzzers, voice tubes, telephones, engine and steering telegraphs and transmitters, searchlights and electric lighting generally, and supplies electric current for all purposes for which it is used, whether it be for operating a turret turning motor, a feed pump, a flat iron, or a cigar lighter. It also supplies portable ventilating fans for use in officers’ quarters and in those portions of the ship which are not easily reached by the ship’s ventilating system.

_____________

1 Title changed June 4, 1920, to Bureau of Engineering.

--1--

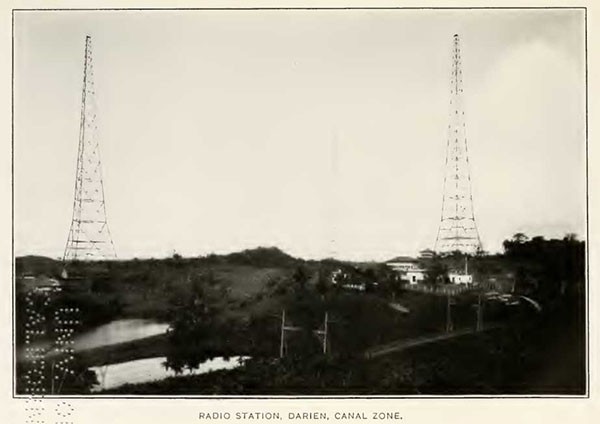

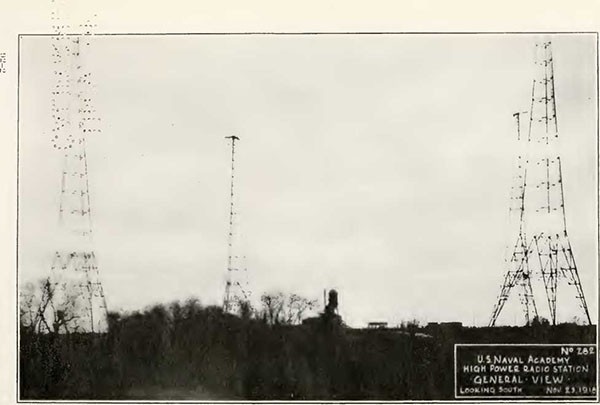

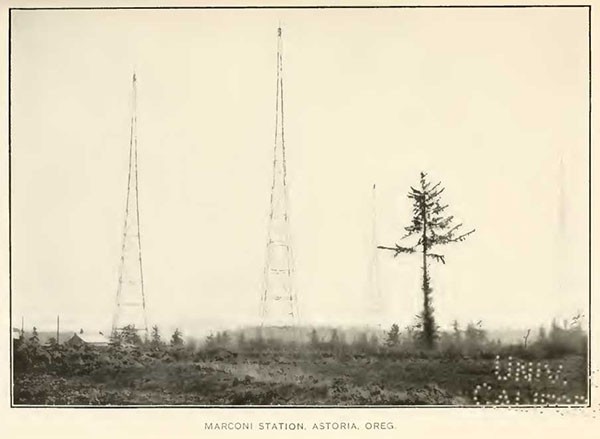

In radio engineering, the Bureau’s field is a wide one, and during the war comprehended the radio installation on every ship that flew the American flag, as well as the design and supply of the equipment for all shore stations in the United States and in our island possessions, and also for a large station just completed at Bordeaux, France.

A new duty that devolved on it during the war was the provision of devices for detecting the presence of submarines and of aircraft.

In the aeronautic field, the Bureau’s duties cover the same kind of work as for surface vessels, i. e., it supplies the machinery and its accessories, and is also charged with responsibility for the generation and supply of gas for observation balloons and for dirigibles.

Besides the duties mentioned, which may be considered as relating chiefly to the material features necessary for operating the ship, many others devolve on the Bureau relating to the health and comfort of the crew. Chief among these is the provision of a supply of salt water for sanitary purposes, and of fresh water for drinking and bathing, which in a battleship of 2,500 men rises to the proportion of the waterworks of a small town. The allowance of fresh water is liberal, and finds its return in the health, the comfort, and the contentment of the crew. Next in importance to this is the provision of machinery and appliances for making ice, and for cooling the refrigerating rooms so that fresh provisions may be always available and thus contribute to the reputation which the Navy enjoys of being the best fed Navy in the world.

The Bureau also heats the ship by steam and by electric power and supplies the same power for cooking.

With so much machinery and so many appliances to care for, it is necessary that the ships be provided with engineering supplies and with hand and machine tools for keeping this equipment in serviceable condition. To accomplish this the Bureau provides a machine shop on each ship with facilities suited to her ordinary needs. For heavier work it equips the shops of the repair ships which accompany the fleet so that any work within reason may be undertaken. Similarly, at navy yards, it decides upon and supplies the equipment of the shops of the Machinery Division, and is held responsible for the adequacy of that equipment.

For engineering supplies, the Bureau decides on the allowance of each kind which shall be issued to each ship, and on the quantity to be carried in stock; it draws the specifications for their purchase, inspects during manufacture those of a technical character, and passes upon the award of contract for them.

It maintains at each shipbuilding establishment that has a contract for building ships for the Navy an inspection force presided over by an officer of experience, whose duty it is to see that the requirements

--2--

of the specifications are faithfully observed, and that when ready for delivery to the Government the ship is in all respects complete and ready for service. A like organization for the inspection of engineering material is maintained in a number of districts into which the country has been divided, whose function it is to see that the chemical and physical characteristics of material comply with the specified requirements before it is shipped to the building yards for incorporation in the ship. Where completely fabricated articles are manufactured the inspection extends to the completed article.

The inspection of fuel is also under the Bureau.

At Annapolis it maintains an experiment station where special problems are investigated and tests made of engineering devices which appear to possess merit and whose installation in naval vessels would be desirable.

It will be seen then that the Bureau’s field is most extensive with regard to the material of the fleet, both in its provision and operation. In sum, it covers everything necessary for propulsion, whether the vessel operates on the surface of the water, beneath it, or in the air. It provides such "public utilities” as a central power plant furnishing light, heat, and power for a multitude of activities necessary for the military efficiency of the ship and the comfort of her crew; a cold-storage plant, telephone service, telegraphic service by radio, and an aqueduct in miniature. It provides also everything necessary for the maintenance in efficient operation of all these services and for many others of less importance.

Just what this represents in figures may be judged from a consideration of a few facts bearing on these activities. During the fiscal year ending June 30, 1918, the expenditures of the Bureau reached the sum of $283,742,767, which is nearly six times those of the preceding year, during three months of which we were at war.

The motive power of the fleet, including that of all the new vessels authorized, the ex-German ships, the patrol and other vessels reached the enormous figure of 11,000,000 horsepower. An appreciation of this power may be had from a consideration of the fact that it is more than twenty times as great as the horsepower of our fleet during the Spanish-American War. It is about eighteen times the power developed on both sides of Niagara Falls, and is also equal to about one-fourth the primary fuel and water power now employed in land service in the United States, not including the locomotives.

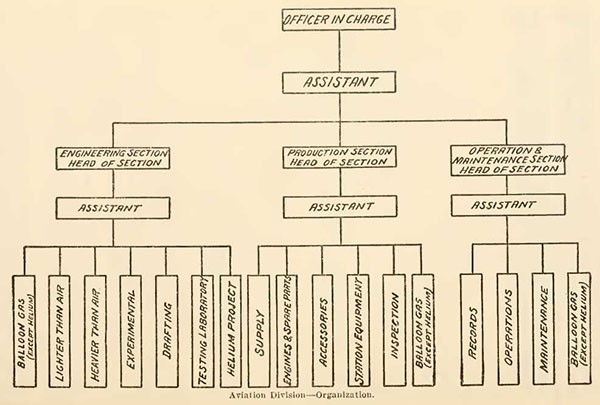

ORGANIZATION AND ADMINISTRATION.

The administration of the Bureau is vested in a chief of bureau, an assistant to the bureau, and a chief clerk: and its various duties, clerical and technical, are performed by divisions, each technical

--3--

division being presided over by an officer specially qualified by experience for the performance of the duties pertaining thereto. These are:

The Clerical Division.

The Division of Design.

The Electrical Division.

The Radio Division.

The Division of Aeronautics.

The Division of Repairs.

The Inspection Division.

The Supply Division.

The Fuel and Personnel Division.

The Division of Logs and Records.

The Clerical Division is in charge of the chief clerk and has supervision of all clerical activities, financial returns and records, and of the file room, and maintains a record of the classified employees of the Bureau and of inspection offices.

The Division of Design has control of the design of machinery and of alterations therein, and prepares the specifications for new machinery. It has supervision of the construction of machinery, as well as of the contracts and payments therefore. It also has under its direction the engineering experiment station and the oil-fuel testing plant.

The Electrical Division has charge of the design and specifications for all electrical apparatus, for interior communication and wiring systems, searchlights, storage batteries, and motors for submarines.

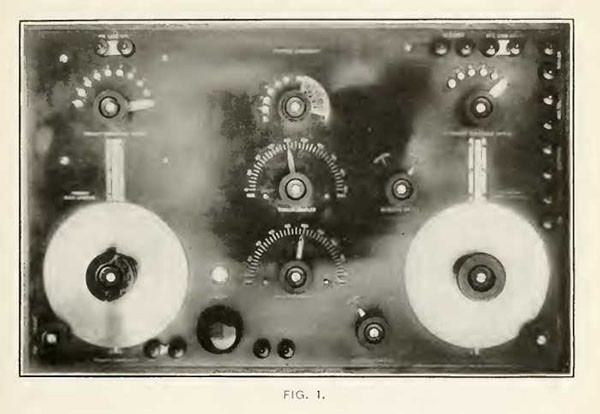

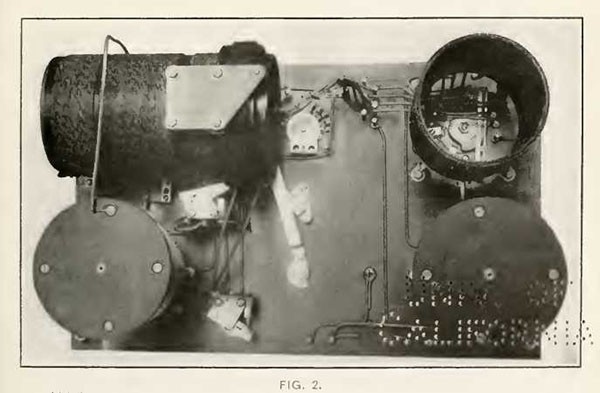

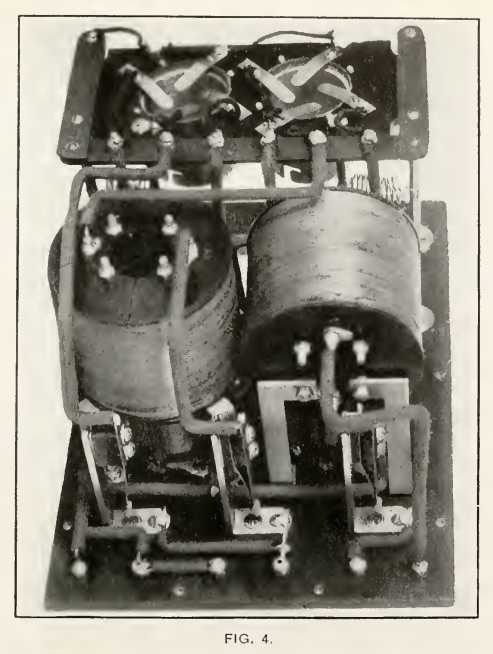

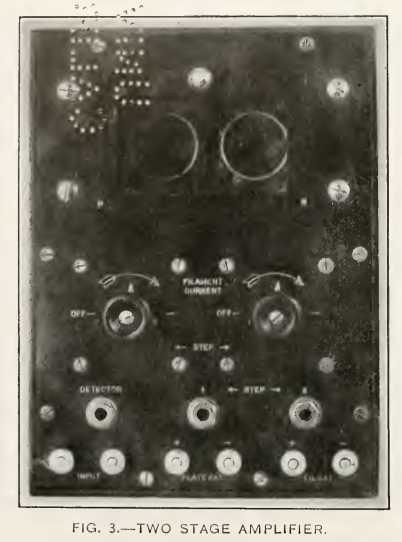

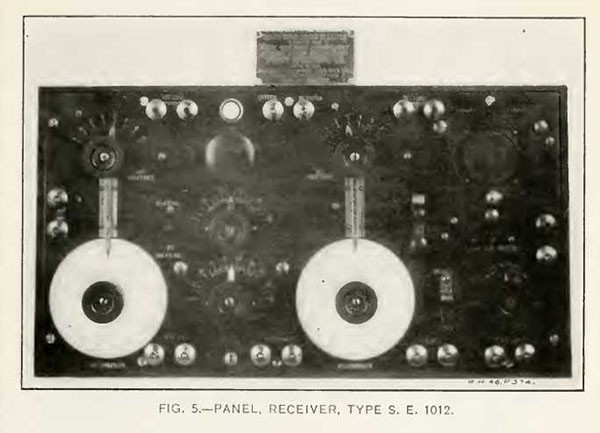

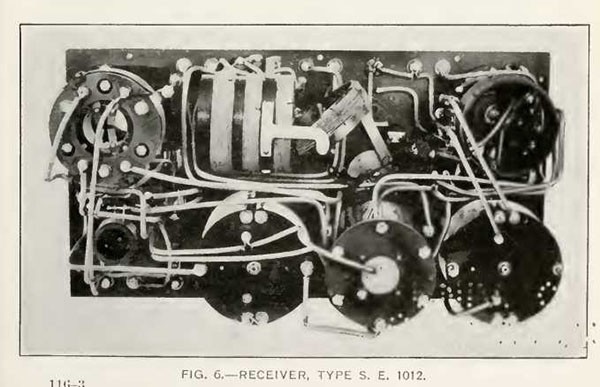

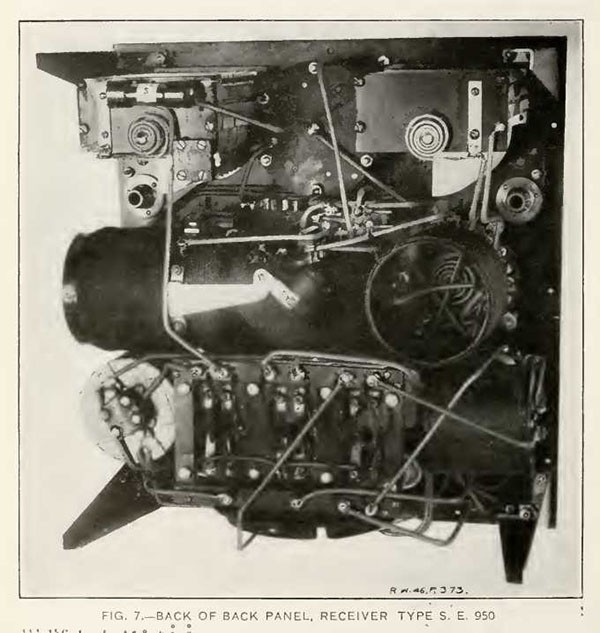

The Radio Division has similar control over the design and supply of all radio apparatus for ship and shore installations and for aircraft, and also of sound detection matters, though during the war this activity was with the Electrical Division.

The Division of Aeronautics has in a general way the same control over aircraft machinery that the Division of Design has over surface craft, but there is necessarily close cooperation between the two divisions respecting certain features of design.

The Division of Repairs has charge of all repairs to machinery of vessels of the fleet, whether done at a navy yard or elsewhere. It also is charged with the manufacture of steam and gasoline engines for power boats, and of records pertaining thereto. Technical questions arising are referred to the division concerned for comment. It prepares allowance lists for all ships.

The Inspection Division is charged with supervision of the inspection of material, of the preparation of specifications, the conduct of tests, and the records of tests.

--4--

The Supply Division handles requisitions from ships and navy yards, prepares Bureau requisitions, analyzes bids received for material, and makes recommendations regarding award of contracts. It also has charge of production matters and of cost of work.

The Fuel and Personnel Division, as its designation implies, handles two widely different subjects. It prepares specifications for fuel and supervises its inspection, and has general supervision of the naval petroleum reserves. In conference with the Bureau of Navigation, it suggests the detail of officers for certain duty of an engineering character.

The Division of Logs and Records prepares and issues blank forms for use in the engineer department of ships, reviews and analyzes the steam logs, and prepares for issue to the naval service engineering information of interest and value.

The chief of bureau determines questions of Bureau policy, authorizes expenditures, and decides important matters of detail as well as many minor ones.

The assistant to the bureau, in the absence of the chief of bureau, assumes his duties and responsibilities. In general he handles routine business in technical and administrative affairs, and has general supervision of the equipment of shops of the Machinery Division of navy yards.

In the absence of the chief of bureau and the assistant to the bureau, the chief clerk acts as chief of bureau.

This organization was not one created for the war or under war-conditions, but was one that had been built up during the preceding 30 years, and is the development of one inaugurated about that time by Mr. Asa M. Mattice, at that time an engineer officer of the Navy. That it stood the test of war conditions and required no change whatever in its basic principle is the best evidence that can be given of its excellence. Additions and extensions were made as conditions dictated the necessity therefor, but no change was made in the system.

PERSONNEL.

Prior to the beginning of the war, the officer personnel of the Bureau consisted of 35 commissioned officers, a number insufficient even under peace conditions to satisfactorily conduct the diversified duties for which the Bureau was responsible. To meet the greatly enlarged demands that would come with war, when every officer who could possibly be spared would be wanted for sea duty, was not a pleasant situation to contemplate, and in preparing for this condition relief was naturally sought from the retired list of the Navy, where officers of naval education and training could be found who would be capable of filling some of the most important positions, and who would bring to the performance of their duty knowledge of

--5--

naval conditions and demands which it would have taken a civilian months and in some cases years to acquire.

Accordingly, in the preparation of the mobilization scheme which was prepared far in advance of our entrance into the war, certain officers of engineering education and training were selected for duty in the Bureau, and in offices of inspectors of machinery and of engineering material, on boards, and for special duty; and but for the fortuitous circumstance that these experienced officers were available, it would have been well-nigh impossible to have handled the enormous business that fell to the lot of the Bureau to administer.

Some of these officers had been retired for age, others for physical disability which did not prevent the performance of shore duty, and all had been notified in advance of the duty to which they would be assigned, so that a telegram directing them to report was all that was necessary to have them on duty again. One served as assistant to the Bureau for nearly a year during the war and for a considerable period thereafter; another, who had previously been in charge of the Division of Design, cheerfully took up the duty of a subordinate in that division; while a third, whom the Bureau intended to utilize in an advisory capacity, became a member of the Priorities Committee of the War Industries Board. Others served either as heads of divisions or as subordinates in the Bureau, and as inspectors. One of the former relinquished a very lucrative position in civil life to resume his naval status. All served with a spirit and an enthusiasm that merit the highest commendation.

But retired officers were far too few in number to fill the demand, and the next step was to survey the list of former officers of the Navy who had resigned and all of whom were eager to return to the service. Many of them were enrolled in the Naval Reserve, but many others occupied such important positions in educational and industrial fields as to make it almost obligatory upon the Government to insist that they continue the work upon which they were engaged.

The next class from which it seemed most desirable to recruit engineering talent was the shipbuilding establishments and the engineering firms who specialized in naval equipment, but here again arose the question of priority. These establishments were daily becoming busier and more necessary than ever to the successful prosecution of the war, and to weaken their organization would be suicidal. In fact it was felt that everything possible should be done to keep those several organizations intact and, if possible, to strengthen them. It was clear that assistance from this field could not be thought of.

Meanwhile many offers of service were made by patriotic engineers who were eager to volunteer in any capacity; and while the services of some were accepted, it was felt that in most cases the applicants

--6--

were either too advanced in years for the subordinate positions to which they would necessarily have to be assigned or that the industrial field offered better opportunity for the exercise of their ability.

With all these conditions confronting us, recourse was eventually had to transferring from the Naval Reserve young officers whose training had been along engineering lines and who were favorably reported on by the district commandant or commanding officer under whom they were serving. In addition the Bureau of Navigation had, upon recommendation of the Bureau of Steam Engineering and approval of the Secretary of the Navy, conducted an examination for the enrollment as ensigns of 100 electrical engineers selected from a list of 250 applicants who had been recommended by the Naval Consulting Board, the National Research Council, and the American Institute of Electrical Engineers. Capt. R. H. Leigh, the assistant to the bureau, was the president of the board. The officers thus appointed rendered excellent service, and several of them were, after limited experience afloat, assigned to duty in the Bureau.

Qualified aviation personnel did not exist, and it was necessary to find men who were known to have a bent toward mechanical engineering problems, and in most cases send them to the Massachusetts Institute of Technology for an intensive course in aviation engineering that had been established there, thence to the airplane or engine factories for a short tour under the inspection officer, and then to duty in the Bureau, where they specialized on one particular part of the power plant of aircraft. This method was also followed in building up the inspection force, some selections being made every three months from each class that passed through the school. The men were awarded a commission in class 5 of the Naval Reserve Force after successfully passing through the weeding-out process and a probationary period of actual service. A few reserve officers were also obtained from the air stations for inspection duty. An excellent class of men who worked loyally and earnestly at all times was obtained.

Advantage was also taken of the transfer of the Coast Guard to the Navy to secure the assignment of some officers of that service to duty in the Bureau and for inspection. It is no less a duty than a pleasure to state that they rendered excellent service.

From these various sources, the officer personnel of the Bureau was recruited until at the time of the armistice it numbered 143, distributed as follows: Officers of the active list, 21; retired officers. 10; temporary officers, 6: reserve officers, 99; Coast Guard officers, 6; Army officers, 1.

These officers, one and all, worked with zeal and devotion. Office hours were forgotten, night work and work on Sundays and holi-

--7--

days, though not continuous, was so generally pursued as to make it almost routine. A night detail was always in effect, one officer being specially detailed for a certain period and his name and telephone number registered so that he might be available at an instant’s notice.

Shortly after the declaration of war, Admiral Sims advised that officers qualified in mechanical and electrical engineering be sent to London where the British Admiralty had expressed a willingness to give the fullest information regarding technical matters which had developed during the war and which should be known to all the Allies. Advantage was taken of this offer to send Commander G. W. S. Castle and Commander S. M. Robinson, who were not only given the widest opportunity for investigation at the Admiralty, but also were permitted to visit vessels of the Grand Fleet at Scapa Flow. The information they acquired was of great value, especially in fire-control work.

Later Lieut. Commander W. A. Smead, U. S. Navy, and Lieut. G. M. Brush, U. S. Naval Reserve Force, were sent to France and England in connection with aircraft material, and Commander J. O. Fisher, U. S. Navy, in connection with submarines. In each case much information of value was obtained.

Early in 1917 the French and the British Governments sent commissions to this country who contributed exceptionally valuable information respecting the methods in vogue abroad for the detection of submarines. The French Commission, composed of Majs. Fabry and Abrahams, brought samples of detection devices and other apparatus which were of great assistance in the development work we were then undertaking. Commander Bridge, R. N. and Sir Ernest Rutherford gave the fullest information respecting the work of the British, which enabled us to begin with the best information obtainable.

Additional assistants for the offices of inspectors of machinery and inspectors of engineering material were obtained through district commandants from the list of enrolled officers and petty officers. In special cases, such as the production officers, who were specially selected men above draft age and of extensive experience, enrollment was made directly by the Navy Department.

For a time inspection of material was seriously hampered because many of our trained assistant inspectors were lured to service under the War Department by offers of a commission and much higher pay than was possible of attainment under the Navy Department. This obtained also to a certain extent amongst civilian employees of the Bureau.

The administrative officers of the Bureau during the period from April 6, 1917, to November 11, 1918, were:

--8--

Rear Admiral Robert S. Griffin, Engineer in Chief, U. S. Navy.

Assistant to bureau, Capt. R. H. Leigh, U. S. Navy.

Assistant to bureau, Capt. O. W. Koester, U. S. Navy (retired).

Chief clerk, Mr. A. C. Wrenn.

Special duty, Lieut. Commander W. L. Cathcart, U. S. Naval Reserve Force.

Rear Admiral A. V. Zane, U. S. Navy (retired), representing Bureau of Steam Engineering on Priorities Committee, War Industries Board.

CIVILIAN PERSONNEL.

While the conditions affecting the filling of the complement of technical officers were such as to cause no little concern, the situation with respect to the civilian working force was one that required unceasing attention.

In January, 1917, this force consisted of 50 clerks and messengers and 37 draftsmen and technical employees, a total of 87. The preparations that were made between that date and the declaration of war were such as to require a considerable increase in the technical force, which increase it was not possible to secure in the orthodox manner through the Civil Service Commission because the appropriation fixed by Congress limited the amount that might be expended for such service and also the number of employees. All bureaus were experiencing the same difficulty, and relief finally came through the Bureau of Navigation, which enrolled in the Naval Reserve in the various grades of yeoman a number of female clerks (reservists F), who were assigned to duty in the Bureau. But for this assignment, it would not have been possible to carry out the preparations that were made before the declaration of war, at which time the total number of employees engaged in clerical work numbered 84, an increase of 34.

The demand for additional civilian assistants increased by leaps and bounds and greatly exceeded the supply of competent availables. Even with a reduction in the requirements, it was difficult to obtain the desired employees. Every means was used to increase the number, such as appeals to business colleges outside of Washington; and though difficulty was experienced, it is gratifying to state that all immediately urgent needs were met and that the efficiency of the Bureau was at no time impaired by lack of adequate civilian force.

On armistice day this force had grown to the following proportions :

| Civilians (clerks) | 170 |

| Civilians, draftsmen and technical employees | 103 |

| Naval reservists | 282 |

| Total | 555 |

--9--

Twenty-five of the civilian employees entered the military or naval service, as follows:

Brady, John B., ensign, U. S. Naval Reserve Force.

Brandon, Valentine N., corporal, 335th Machine Gun Battalion.

Conrad. Amos W., jr., corporal, Headquarters, 372d Infantry.

Dean, William R., jr., corporal, 164th Depot Brigade.

Dickson, Walter S., carpenter’s mate, second class, U. S. Naval Reserve Force.

Elliott, Charles A., private, U. S. Marine Corps.

Gladmon, Cassin G., private, Sanitary Detachment, Camp Meade.

Goldstein, Bernard S., chief yeoman, U. S. Naval Reserve Force.

Hill, Guy, captain, Signal Corps, U. S. Army.

King, Benedict J., musician, Headquarters, 371st Infantry.

Lanigan, Arthur L., Students Army Training Corps.

Laning, Benjamin A., ensign, U. S. Naval Reserve Force.

McCutcheon, Ross, private, Tank Corps.

Manitsky, Benjamin P., sergeant, Headquarters, Camp Upton.

Martin, William L., private, Tank Corps.

Reubenbaum, Samuel P., Headquarters, 79tb Division.

Roberts, Daniels Q., chief yeoman, U. S. Naval Reserve Force.

Rundorff, Robert L., Officers Material School, U. S. Naval Reserve Force.

Sparrow, Marion C., private, Tank Corps.

Spring, Arlington C., second lieutenant, Engineer Corps. U. S. Army.

Stein, Anders C., chief yeoman, U. S. Naval Reserve Force.

Tallman, Henry W., second lieutenant, Aviation Corps, U. S. Army.

Volinsky, Harry, corporal, 67th Infantry.

Woulfe, Robert E., chief yeoman, U. S. Naval Reserve Force.

The principal civilian employees of the Bureau during this period were:

| Name. | Rating. |

| Wrenn, A. C. | Chief clerk. |

| Moran, F. S. | Clerk to Engineer in Chief. |

| Christman, A. L. | Financial clerk and accountant. |

| Warman, F. C. | Chief of Files Division. |

| Biggers, A. B. | Principal clerk, Electrical Division. |

| Haslett, L. J . | Principal clerk, Radio Division. |

| Hughes, M. G. | Principal clerk, Supply Division. |

| Fessenden, A. G. | Principal clerk, Ships’ Repairs Division. |

| Orrison, A. M. | Miscellaneous furniture and supplies. |

| Sicard, W. F. | Chief machinery draftsman. |

| Thurston, P. K. | Assistant chief machinery draftsman. |

| Gatchel, T. L. | Chief electrical draftsman. |

| Trogner, A. M. | Chief radio draftsman. |

| Carter, G. O. | Consulting engineer, hydrogen gas. |

| Williams, Karl D. | Metallurgical engineer. |

| Herndon, E. G. | Machine tool expert. |

Throughout the entire period of the war this force worked with an enthusiasm which bespoke their loyalty to the country and their personal interest in winning the war.

--10--

![OFFICERS, ENLISTED PERSONNEL AND CIVILIAN EMPLOYEES OF BUREAU OF STEAM ENGINEERING, 1917-1918. [Pt. I] OFFICERS, ENLISTED PERSONNEL AND CIVILIAN EMPLOYEES OF BUREAU OF STEAM ENGINEERING, 1917-1918. [Pt. I]](/content/history/nhhc/research/library/online-reading-room/title-list-alphabetically/h/history-bureau-engineering-during-wwi/_jcr_content/body/image_1636857748.img.jpg/1469114882044.jpg)

![OFFICERS, ENLISTED PERSONNEL AND CIVILIAN EMPLOYEES OF BUREAU OF STEAM ENGINEERING, 1917-1918. [Pt. II] OFFICERS, ENLISTED PERSONNEL AND CIVILIAN EMPLOYEES OF BUREAU OF STEAM ENGINEERING, 1917-1918. [Pt. II]](/content/history/nhhc/research/library/online-reading-room/title-list-alphabetically/h/history-bureau-engineering-during-wwi/_jcr_content/body/image_171814690.img.jpg/1469114906972.jpg)

Coincident with this great increase in the personnel of the Bureau came a demand for additional office space. This had been found to be too restricted even for the business of peace times, and the first step in acquiring more was by permission of the Secretaries of State, War, and Navy, to close the southeast driveway of the State, War, and Navy Building, in which the Bureau was then quartered, and to construct therein a one-room frame structure. Later, two additional rooms were acquired by inclosing two balconies leading off the quarters of the Bureau. Then followed occupancy of the hall on the third floor, the renting of three rooms in one building, and two upper floors of two old remodeled buildings at the corner of Seventeenth and G Streets NW. In July, 1917, two divisions of the Bureau were removed to the latter quarters, and in March. 1918, sufficient space was secured in the temporary Government buildings erected at Seventh and B Streets NW. to provide quarters for another division.

While the acquisition of this additional space gave the divisions that remained in the building a little more elbow room, the relief was only temporary, and in a short time the crowded condition again prevailed, and it was not until August. 1918, when the new Navy Building at Seventeenth and B Streets was completed that the Bureau really had sufficient space to transact business properly.

The delays incident to having the work of the Bureau carried on in so many buildings were vexatious to a degree: for while a good telephone and messenger force was established, the chief of Bureau lost that personal contact with the officers in charge of the work of the outlying divisions which is so necessary to satisfactory and expeditious conduct of business.

As a corollary to the increase in personnel and quarters, there came also a big demand for office equipment and supplies. This demand was successfully met, due in no small measure to the splendid cooperation of the Supply Division of the Department, which rendered every assistance in obtaining these necessities in the most direct manner possible.

It will be seen then that when the armistice was declared the Bureau’s force comprised a total of 698 officers and employees and occupied about 2 acres of office space in the new Navy Building.

PRELIMINARY PREPARATIONS FOR WAR.

The first work done by the Bureau of Steam Engineering after the outbreak of the war in August, 1914, in order to keep in touch with the general situation and to make such preparations as might be necessary to insure the readiness of the material under its cognizance to meet any emergency, was to request the Department to

--11--

send abroad an officer qualified to investigate the radio situation. This action was taken August 17, 1914, as shown by the following letter:

132447-787-W

Navy Department,

Bureau of Steam Engineering,

Washington, August 17, 1914.

From: Bureau of Steam Engineering.

To: Department (Material and Personnel).

Subject: Assignment of specially qualified officer as observer of radio operations in European war.

1. The Bureau invites the Department's attention to the opportunity that is presented in connection with the proposed employment of Army transports in European waters of obtaining information of great value to the naval service. A trained observer having authority to transfer from one of these ships to another, or to United States naval ships in the war zone, could, by simply listening in to the radio communication carried on, acquire information not only as to foreign material equipment but also as to principles of organization and tactical operation in regard to which our service has never received any information and which probably never can be acquired by any other method. It is essential, however, that the officer selected for this duty be one whose qualifications embrace not only expert operating ability but also special training in radio organization as applied to the intricate requirements of tactical use. It happens conveniently that Lieut. S. C. Hooper has just been relieved as fleet radio officer, Atlantic Fleet, and should now be available for this duty. This officer has been engaged during the last two years in establishing an efficient radio organization in the fleet and he is preeminently qualified for the duty suggested. In fact, his special training for this particular work could not have been improved upon by design. The Bureau recommends that the necessary arrangements be made with the War Department and that orders be issued to Lieut. Hooper giving him the largest allowable discretion in obtaining the data desired.

(S.) Griffin.

Orders were issued in accordance with the above recommendation and Lieut. Hooper sailed on the Olympic the latter part of August, 1914, and remained abroad until January, 1915, returning on the St. Paul. The time was spent in England, France, Ireland, Belgium, and Holland. At the time of Lieut. Hooper’s visit to Belgium it was occupied by the Germans, but he was, nevertheless, able to obtain information of value.

It was difficult to obtain information regarding radio matters from the Allies on account of the strict censorship that prevailed, but Lieut. Hooper’s practical knowledge enabled him to listen in at various places and thus to acquire complete knowledge regarding the system employed by them and the use to which radio was put. This information was later found to be correct when we entered the war. He also inspected the apparatus under manufacture for the British Government and visited the principal high-power station at Carnarvon, Wales, which, at that time, was the largest station in existence. The information of most value that he obtained was in

--12--

regard to the distant control of radio stations, a system which was later adopted for our Navy.

As a result of the complete information acquired, a board was appointed with a view to improving the communication service of our Navy. The general plan outlined by this board was the foundation of the present organization of the Naval Communication Service and has remained practically unchanged.

On March 13, 1915, the General Board submitted to the Department an outline of a plan of preparedness. This was approved by the Department May 2S, 1915, and the Bureau was directed to make the first report in compliance with this outlined plan in one month following the date of its approval, and subsequent reports quarterly. This was followed by a letter from the Chief of Naval Operations, June 10, 1915, directing the inspection of merchant ships to determine their suitability for use by the Navy, and calling for a report regarding the alterations and additions that would be necessary in order to make them suitable for Navy service.

The first report of the Bureau, dated June 28, 1915, stated that nearly all merchant ships except those for repair and supply ships could be put in service without delay, or without great expenditure; that plans were under way for the conversion of two merchant ships to repair ships; that conferences had been had with the Bureau of Supplies and Accounts respecting supply ships and refrigerating ships; that all auxiliaries could be immediately supplied with searchlights and blinker sets, and with auxiliary radio sets. General comment was made on other features of the order affecting the supply of engineering material. It was stated that the Bureau of Navigation had been furnished with a list of retired officers required for duty under the Bureau; that the Bureau would be ready to make specific recommendations regarding merchant ships as soon as reports of the Board of Inspection and Survey were received. This was followed, on October 8, 1915, by a report that plans had been prepared for the conversion of two repair ships, and attention was invited to the fact that no reports of inspection of merchant ships had yet been received.

October 28, 1915.—A letter was addressed to the commander in chief, Atlantic Fleet, requesting that supply officers of two ships of the fleet be directed to fill in, opposite certain items of the allowance list, the quantity of such material that had been used during six months or a year—this to enable the Bureau to prepare a stock list.

November 9, 1915.—The commandants of all navy yards and stations were directed to submit a detailed plan for the expansion on short notice of the facilities of the machinery divisions of the several yards and stations, and to submit an estimate of the time and cost

--13--

for accomplishing this. A similar letter was sent to the naval station, Guantanamo, on January 8, 1916.

November 12, 1915.—The commanders in chief of the Atlantic, Pacific, and Asiatic fleets, Torpedo Flotilla commander, and the commander of the Cruiser Squadron, Atlantic Fleet, were directed to report the engineering material they considered desirable to keep on hand in order to secure a state of preparedness for war. Suggestions were requested as to the engineering material which it was desired to carry on fighting ships, repair ships, and tenders under war conditions, and what similar material should be kept in store for emergency shipment of the fleets.

November 13, 1915.—Letters were addressed to all inspectors of engineering material directing them to report the extent to which the capacity of manufacturing plants in their several districts who were engaged in the manufacture of important engineering material could be increased in case of emergency to meet a sudden demand. A list of the important material was given, and in a letter of December 1, 1915, the inspectors were directed to include machine tools in the list. Similar letters were addressed under date of January 25, 1916. to the inspectors of machinery at the Busch-Sulzer Co., St. Louis. Mo., and at the Babcock & Wilcox Co., Bayonne, N. J., to report on manufacturing plants in the vicinity of their headquarters.

November 22, 1915.—A similar letter was addressed to inspectors of engineering material for a report on articles of electrical equipment.

November 23, 1915.—Letters were addressed to the two principal manufacturers of submarine storage batteries and to the one manufacturer of submarine signaling apparatus asking that they submit a list of the articles, or component parts thereof, which they usually carried in stock, and to keep the Bureau advised of changes as they occurred. A similar letter, dated January 5, 1916, was addressed to the manufacturers of searchlights.

November 30, 1915.—Letters were addressed to the inspectors of machinery at all principal shipyards to report on the machinery repair and building work that could be undertaken in an emergency at the works to which they were assigned, and also of other ship and engine plants in the vicinity that could be relied upon to assist in the preparation for service of the auxiliary fleet.

December 3, 1915.—Letters were addressed to the commandants of all navy yards and stations directing them to submit lists of material which they considered it desirable to carry in stock.

December 7, 1915.—A letter was addressed to the industrial manager, navy yard, Portsmouth, directing him to submit a report on the maximum quantity of articles that could be manufactured with present facilities by an increase in the number of employees, and

--14--

similar information regarding the output after 150 days by an increase in the facilities as well as in the number of employees. (The Portsmouth Navy Yard specializes in the manufacture of electrical fittings.)

The second report was dated December 31, 1915, and contained specific recommendations regarding improvements necessary in the machinery divisions of navy yards in order to increase their capacity for work. Difficulty in obtaining machine tools was pointed out. Report was made of the facilities of a number of shipyards and repair plants. Special attention was called to the desirability of increasing the stock of engineering material at navy yards, and much information given regarding sources of supply and available material of an engineering character. A list was given of the auxiliaries to be taken over or chartered, and recommendation made in each case as to the changes that would be required.

Special attention was directed to the inadequacy of the war detail of officers and technical employees under the Bureau, and to the duplication of work by the Navy Department and the War Department, and by different bureaus of the Navy Department, in collecting information to carry out the Department’s order. Recommendation was made for obtaining funds to prepare navy yards so that they might quickly increase their facilities.

This report, which might be considered the first report under the operation of the plan outlined by the General Board, covered detailed reports on 10 navy yards and stations, on 22 shipbuilding and repair establishments, and on 300 manufacturing plants which might be called upon to supply engineering material. The report was of such a comprehensive character as to evoke a commendatory letter from the Chief of Naval Operations. Its preparation, as also that of subsequent ones, was under the special supervision of Capt. R. H. Leigh, assistant to the Bureau.

January 4, 1916.—Inspectors of machinery were directed to report the changes they considered necessary in their office force and office space in order to meet war conditions. The detail of officers assigned for each office under the mobilization plan was forwarded and suggestions requested regarding any modifications that might be considered necessary. A similar letter was sent to the inspectors of engineering material on January 5, 1916.

January 15, 1916.—The Bureau reported to the Department on the difficulty of obtaining engineering supplies and the delay occasioned thereby, cited numerous cases, and recommended that Congressional action be secured in order to assure procurement of such material.

January 28, 1916.—A letter was addressed to the commandants of all navy yards and stations expressing appreciation of the work that had been done in connection with the Bureau’s report of De-

--15--

cember 31, 1915, and quoted the commendatory letter received from the Chief of Naval Operations. The opinion of the commandants was requested regarding personnel, and a statement called for as to whether the detail fixed in the mobilization scheme was considered satisfactory. Similar letters were addressed to the inspectors of engineering material and inspectors of machinery.

January 31, 1916.—The commandant of the navy yard, New York, was directed to report on the engineering work that could be undertaken by ship and engine building and repair plants in the vicinity of New York and Jersey City in connection with the alteration, repair, and outfit of vessels that might be taken over for auxiliary service. A similar letter was addressed to the inspector at the Babcock & Wilcox Co., under date of January 25, 1916; to the Maryland Steel Co., January 29, 1916; to 21 other ship and engine establishments on February 4, 1916; to 10 others on February 8, 1916; and to three others on March 7, 1916.

February 5, 1916.—The inspectors of engineering material were directed to ascertain the usual output and also the emergency capacity of manufacturing establishments in their districts for the manufacture of 20 different articles of equipment, which were enumerated by the Bureau.

The third report was dated March 31, 1916, and followed the general line of the preceding one. It gave an estimate of the cost to equip the machinery divisions of navy yards for building battleships, and noted the addition of certain large tools at Mare Island Navy Yard costing $133,000. It gave details of the building and repair facilities of 45 private yards and the principal details of 66 merchant ships then under construction, besides information from 80 manufacturing establishments for the supply of engineering material; a summary was given of the recommendations made in the case of 38 ships which had been inspected by the Board of Inspection and Survey.

Special attention was invited to the difficulty in obtaining material, and the Bureau’s recommendation previously made that authority be obtained from Congress to place an embargo on the export of certain material was quoted. Note was made of the increased cost of material.

A suggestion was made for the employment of store ships as distinguished from supply ships, and a list given of engineering supplies which should be carried by supply ships. A list was also given of the personnel of the offices of inspectors of machinery and inspectors of engineering material recommended as “war personnel.”

Under date of April 19, 1916, a memorandum was addressed to the Assistant Secretary of the Navy, giving the organization of the material branch of the radio service, which is under the direction of

--16--

the Bureau of Steam Engineering, in which it was stated that there existed in the Bureau a list of the material which various manufacturers were capable of furnishing promptly in the event of war, and also what they could do in a specified time. The Department was also advised that the active cooperation of the Marconi company had been secured for installation of radio apparatus.

The fourth report was dated June 30, 1916, and contained estimates for equipping submarine bases. Information similar to that contained in preceding reports was given on 2 shipbuilding and repair establishments and 14 manufacturing plants. A list was given of 43 merchant ships for which new equipment necessary to be installed was given. This report also contained a summary of what had been done during the year and noted that detailed plans had been submitted to the Department for the expansion of the facilities of navy yards; that reports had been made on 71 shipbuilding and repair plants; and that the inspection reports of merchant ships numbered 112. Difficulty in securing material was emphasized, and the organization of the inspection service submitted.

The fifth report was dated September 30, 1916, and contained details of 2 shipbuilding and repair plants and of 6 engineering supply establishments. It recommended that a reserve stock of important engineering material be kept on hand, and that estimates be submitted to Congress for the purchase of it. A list of material required to equip merchant ships was given, amounting to $495,000. It was noted that the Department approved the Bureau’s recommendation regarding the civilian personnel in inspection offices.

The sixth report was dated December 31, 1916, and contained further details of shipbuilding and repair plants of 15 additional establishments for the supply of engineering material. It gave a list of engineering material that should be provided, amounting to $2,262,500.

The seventh report, dated March 31, 1917, noted the allotment of $267,000 under this Bureau from the appropriation of $18,000,000 for the improvement of navy yards, and stated that additional allotments of $2,744,000 were required. It gave a summary of material required to meet war requirements, to cost $19,115,000. Recommendations were made for the conversion of 28 merchant ships and 35 patrol boats.

THE DESIGN AND CONSTRUCTION OF MACHINERY.

The Act of August 29, 1916, provided for the largest building program that was ever authorized by any Congress. It included 10 first-class battleships, 6 battle cruisers, 10 scout cruisers, 50 destroyers. 9 fleet submarines, 58 coast submarines, 1 special submarine, 3 fuel

--17--

ships, 1 repair ship, 1 transport, 1 hospital ship, 2 destroyer tenders, 1 fleet submarine tender, 2 ammunition ships, 2 gunboats, the construction of 66 of which was directed to be commenced as soon as practicable.

The design of machinery for these latter was well under way when war was declared; that for the 4 battleships had been completed and contracts awarded, but the design for the 4 battle cruisers was not far advanced. Decision had, however, been reached to install electric motor driven machinery in all the capital ships; and as the decision in the case of the battle cruisers was the subject of much comment, it would seem that this is a proper place to give a short history of the Navy’s adoption of this type of machinery for its capital ships.

ELECTRIC DRIVE.

In 1909, Mr. W. R. L. Emmet, the consulting engineer of the General Electric Co., represented to the Navy Department the great advantage which would be derived by equipping one of our old battleships with electrically operated machinery, and submitted a tentative proposition for such an equipment. As the number of our battleships at that time, even including the old one under consideration, was too small to admit of assigning one to purely experimental work, the Navy Department declined to enter into the scheme proposed, which was substantially that the Government should buy the machinery and experiment with it. The Navy Department and the Bureau of Steam Engineering were, however, rather favorably impressed with the general idea contained in the proposition, and a year or two later, under the administration of my predecessor, Rear Admiral (now captain) Hutch I. Cone, when the machinery of two colliers was under consideration, it was decided to equip one of them with electric drive and the other with turbine reduction gear, which had been strongly recommended by Rear Admiral Melville, formerly Engineer in Chief of the Navy.

The collier Jupiter was the one designated to be equipped with electric drive. Her machinery was of about 7,000 horsepower, transmitted through two shafts; but, so far as the electric generator was concerned, she was in fact no better than a single-screw ship, because her entire power was concentrated in one generator. The machinery was built by the General Electric Co. and installed on a “no-cure, no-pay” basis—i. e., the General Electric Co. agreed to remove the electric machinery if it did not prove satisfactory on trial and in service for a limited period; and so carefully was this provision kept in mind that the propeller shafting and the steam piping, which were installed by the Government, were so arranged

--18--

that no change would be necessary in them in case it should have been necessary to remove the electric machinery and install reciprocating engines.

The Jupiter has now been in service more than seven years, and has never been inactive one day on account of her electric machinery. So much importance did the Navy Department attach to this installation that she was officered and manned by a naval instead of by a merchant crew, and was brought from the Pacific to the Atlantic in order that the most reliable information might be obtained in regard to the working of this machinery. So great was the interest of the Bureau of Steam Engineering in the success of this first installation that the chief of the bureau consented to the temporary detail of the assistant to the bureau, Capt. S. S. Robison, to command her in order that upon his return to the Bureau first-hand information might be available in a consideration of questions that might arise regarding this or future installations. For the same reason, Commander U. T. Holmes, at the time in charge of the Division of Design, was detailed as a member of the board to witness the final trials of the ship.

In this way the Navy Department had accumulated a mass of valuable information regarding the operation of electric machinery; and so satisfactorily had this first installation on the Jupiter proved that the Department, in 1914, decided that the information then available was sufficient to justify the installation of electric machinery in the battleship New Mexico (formerly California) building at the New York Navy Yard. Subsequent experience with the Jupiter confirmed the earlier impressions, and the decision of the Navy Department to continue such installations was the best kind of evidence that no difficulty had been experienced with her installation.

When it came to the design of the battle cruisers, for which the speed and power contemplated were far in excess of the speed and power of any ship afloat, the question as to the kind of machinery which should be installed was naturally one of the greatest concern. Information which had been received from abroad had shown the paramount necessity of giving under-water protection to ships such as had never been contemplated before. Fortunately, electrically operated machinery lent itself admirably to the conditions imposed by protection, besides which it also possessed other military advantages. It was therefore decided that electric machinery was the only type that could be installed and make these ships what it was desired they should be, and it may be safely said that the protection provided in their design is the greatest that human ingenuity' could devise without encroaching upon the space for the installation of machinery.

--19--

For similar reasons, the same type of machinery was included in the design for the four battleships that were carried in the act of August 29, 1916, and of the six authorized in the acts of March 3, 1917, and July 1, 1919. When bids were received for the four of the 1916 act, it was clear that the shipbuilders were unwilling to give •the usual guaranties regarding the satisfactory operation of the machinery, but so confident was the Department of the great advantage to be secured by the use of electrical machinery that, after conference between the shipbuilders and the electrical firms, it was decided to make a change in the usual form of contract, whereby the Navy Department relieved the shipbuilder of responsibility for the machinery subsequent to a successful dock trial, and entered into a contract with the electric companies covering responsibility and performance during the usual contract period.

While these preliminaries were under discussion, and after the bids for the battle cruisers had been received, the inventor of the Curtis turbine sent the Secretary of the Navy a long telegram representing to him that a great mistake would be made if electric machinery were put in the battleships; that Great Britain was using-geared turbine machinery, and that a commission should be appointed to investigate the whole subject before final decision was reached. This was followed by a letter amplifying his telegram, and later by another letter addressed to the President of the United States covering practically the same ground. Mr. Curtis also put in print substantially the same arguments that he advanced in his letter to the Secretary of the Navy.

The identical arguments used by Mr. Curtis were advanced by a prominent manufacturer of electrical apparatus who interviewed the Secretary of the Navy on the subject, and who later approached other officers of the Department and the chairman of the Naval Committees of Congress. Appeals were made to engineers of prominence to urge the Department to adopt mechanical reduction gear or at least to refer the question to a board of “impartial expert” engineers for decision as to the type of machinery to be used. Just where such a board could be found was not stated, and as the Navy Department was of opinion that the most expert electrical engineers were in the employ of the two big electrical companies to whom the construction of the machinery must necessarily be intrusted, it could hardly be held that representatives from those firms, however "expert” they might be, could be classed as “impartial.” For the same reason, those who were behind the propaganda to compel the installation of mechanical reduction in these ships could not be put in this category. Obviously, the question was one for the Secretary of the Navy to decide, and the attitude of the Department is well expressed

--20--

in Secretary Daniels's letter of March 26, 1917, to a prominent mechanical engineer who had yielded to importunities to address the Navy Department on the subject. The letter follows:

Sir: Receipt is acknowledged of your letter of March 21, in regard to the use of electric drive in our battle cruisers, from which I note that you do not consider that you are in a position either to commend or condemn the type of machinery that has been adopted.

For the past live months an industrious propaganda has been waged, by parties interested in mechanical reduction gear to have that type of machinery substituted for the electric drive, and it is a noteworthy fact that during that time only seven people other than you have yielded to the importunity of the propagandists to write to the Navy Department in protest of its action. Of those who have written, one was a chemist, one an editor, two electrical engineers, one a college professor, one a mechanical engineer, and one whose name can not be found in the list of members of the mechanical or electrical engineers, and who seems to he unknown to prominent engineers— not one “eminent” engineer among them. I make this statement because of your prominence as an engineer, and in order that you may know how slow the engineers of the country have been to yield to the clamor of people who see fat royalties escaping them with the use of electric drive.

It is clear from your letter that yon have not been fully informed in the matter, and in order that you may have better information than you now possess, I will say that the Navy Department has a number of competent engineers in its employ, that their method of approaching an untried scheme is the same as yours, and that it was followed to the letter in this case. In addition to this, we have the benefit and advice of the best engineering talent and experience of the large shipbuilding establishments and of the large electric companies, and the fact that every shipbuilding company that bid made a proposal for electric drive, and only one a proposal for geared as well as electric drive, would seem to be abundant evidence that they have no doubt of the satisfactory operation of the latter. Even Mr. ----------, whom you quote (and whose experience in large undertakings I feel sure you would not substitute for that of the engineers of the large electric companies), when asked by me if he had any doubt of the satisfactory working of the electric machinery, answered that he had not.

I have given this full consideration to your letter because it so happens that you are the only mechanical engineer of prominence who has written me in regard to it, and also because I want you and the American people generally to know that I and the officers of the Navy concerned in the design of these ships are just as anxious that they shall be a success as you or anybody else, and probably more so than some of the interested people behind this propaganda. We feel confident that the ships will be a pronounced success, and that they will confound the very people who would deny to us the great advantage that will come from the experimental work that we have conducted during the last three years. They will have electric drive.

Very respectfully,

Josephus Daniels,

Secretary of the Navy.

A member of the Naval Consulting Board suggested to the chief of bureau that the matter be referred to that board for an opinion as to whether electric drive was suitable for installation in these

--21--

ships, but it was pointed out to him that nearly all the electrical engineers on the board were in the employ of one or the other of the two big companies who would be called upon to build the machinery, and that an opinion from the board in such a case would be open to the criticism that it was not unbiased. He was also informed that the Navy Department was satisfied, and that the only people who were not satisfied were those who were interested in the adoption of another type of machinery, and that as they were not in any manner responsible for the success of the ships as a military unit, the decision might well be left with those upon whom responsibility rested.

The type of machinery adopted is the only one that could be installed in the space available, and the only one that could give the protection which is considered a necessary feature of the design of the ship.

It should be remembered that when this decision was reached we had only the experience of one installation in a collier, but since then the New Mexico has been completed, and every report from her shows how superior her electric drive is to that of any other arrangement of turbine equipment that could have been devised.

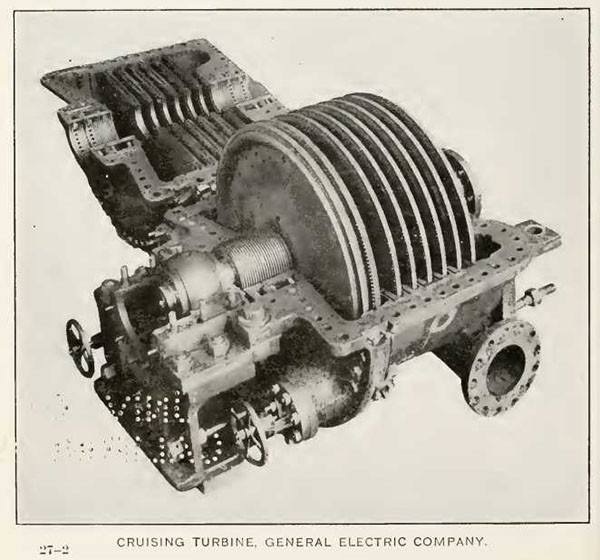

The technical side of the question in its application to naval ships is of such interest and importance as to justify a brief recital. It is clearly recognized that in order to obtain economy in a turbine it must be operated at high rotational speed, and that to obtain the greatest efficiency from a propeller it should run at low speed. In order, therefore, to secure the most efficient combination in intermediate reducing mechanism must be introduced between the turbine and the propeller. Those that admit of application are either mechanical, electrical, or hydraulic, but there are so many objections to the latter that it may be dismissed from consideration.

With mechanical reduction gear for the large installations, such as those of battleships, the high-pressure and low-pressure turbines for each screw are arranged in series and mounted on separate shafts, each shaft carrying a pinion that engages a single reducing gear of large diameter keyed to the propeller shaft. Each low-pressure turbine shaft carries also an astern or backing turbine. The principal objection to this arrangement is the necessity for the backing turbine, which gives at best only about 40 per cent of full power, as considerations of weight and space forbid the use of a backing turbine of the same power as the ahead turbine. The result is a short turbine operating at low economy.

Consider now the electric combination, where the turbine is, as before, the primary source of power, but wherein instead of operating a screw propeller it operates an electric generator. The electric power thus developed is transmitted to motors attached to the pro-

--22--

peller shafts, and the motors operated to turn the propellers ahead or astern. In other words, there is a central power plant for generating current, and this current is transmitted to the point of application of the power. There is no backing turbine, the reversal being accomplished with ease and certainty through the motors, and with this great advantage over the mechanical reduction—full power is always available.

In large installations it is possible to distribute the power amongst several units in such manner as to secure high economy at both full and cruising speeds.

The advantage which electric reduction gives over other types may be summed up in these:

Greater flexibility and control in the use of power.

Improved economy in every-day service and good economy at full speed.

Less liability to serious derangement.

Less likelihood of speed of ship being seriously affected in the event that turbines are injured.

Military superiority that comes from greater maneuvering power.

Military superiority due to improved underwater protection.

This extended statement is given because of the importance of the subject and because the design of machinery for these battleships and battle cruisers, authorized to meet war emergencies, represented a power equipment of no less than 1,560,000 horsepower, the battle cruisers alone accounting for 1,080,000 horsepower.

While activities of the Design Division were concerned chiefly with other types of ships, work on the battle cruiser design was carried on as opportunity offered, but no work was done on the ships themselves.

Work was prosecuted on the battleships Mississippi and Idaho, building by contract, and on the Tennessee and California, building at the navy yards, New York and Mare Island, respectively. The Mississippi was delivered December 18, 1917, but the Idaho was not completed until some time after the signing of the armistice.

The officers of the Design Division were:

In charge of division Rear Admiral C. W. Dyson, U. S. Navy:

Computing section: Rear Admiral F. H. Bailey, U. S. Navy, retired.

Surface vessels except destroyers: Commander J. O. Richardson. U . S. Navy2; Commander S. M. Robinson, U. S. Navy; Lieut. Commander W. C. Owen, U. S. Navy; Lieut, (j. g.) T. M. Brodie, U. S. Naval Reserve Force.

Destroyers: Lieut. Commander A. T. Church. U. S. Navy3; Lieut. Commander F. W. Sterling. F. S. Navy, retired. Succeeded by Com-

--23--

mander N. H. Wright, U. S. Navy; Ensign P. L. Emerson, U. S. Naval Reserve Force.

Internal combustion engines: Commander J. O. Fisher, U. S. Navy; Lieut, (j. g.) G. S. Diehl, U. S. Naval Reserve Force; Lieut, (j. g.) R. P. Sanborn, U. S. Naval Reserve Force.

Contracts: Lieut. Commander F. W. Sterling, U. S. Navy, retired.

SCOUT CRUISERS.

That a design of machinery which is desirable in one type of ship may not be suited to the conditions that must be met in a different type is exemplified by the fact that the design for the scout cruisers, the contracts for six of which were let in July and August, 1917, is mechanical reduction gear and not electric reduction. Although the horsepower of these ships is 90,000, the conditions of design and the limitations of space necessary to permit of all the military features to be embodied in the design made it impossible to install anything but a mechanically geared turbine. The conditions were, in fact, almost identical with those met in destroyers.

Although the contracts were awarded a few months after the declaration of war, the urgent necessity for building destroyers and patrol vessels made it impossible to do any work of consequence on the machinery of these vessels until after the signing of the armistice.

DESTROYERS.

Immediately upon the entry of the United States into the war it was determined to concentrate construction upon such types as were most necessary, taking into consideration the time required to construct such vessels. The reports from our representative at the seat of war emphasized in the strongest terms possible the urgent need of destroyers and generally of small craft that might be utilized in combating the submarine. It was, therefore, early determined that this emergency construction should consist of:

Destroyers,

Submarine chasers,

Small destroyers (eagles),

Cargo vessels,

Submarines,

Conversion of troop ships,

Conversion of repair ships,

Mine sweepers,

Seagoing tugs,

Harbor tugs,

and that the precedence should be as given above.

______________

2 Until June 26, 1917.

3 Until June 1, 1917.

--24--

In order that there might be the maximum possible production, the following principles of action were formulated :

1. The adoption of standard design covering general features of construction.

2. The adoption of the smallest practicable number of detail designs of propelling machinery and auxiliaries, taking into consideration expansion of existing facilities.

3. Study of materials of construction to determine where substitution of material could be made with the least possible sacrifice of efficiency.

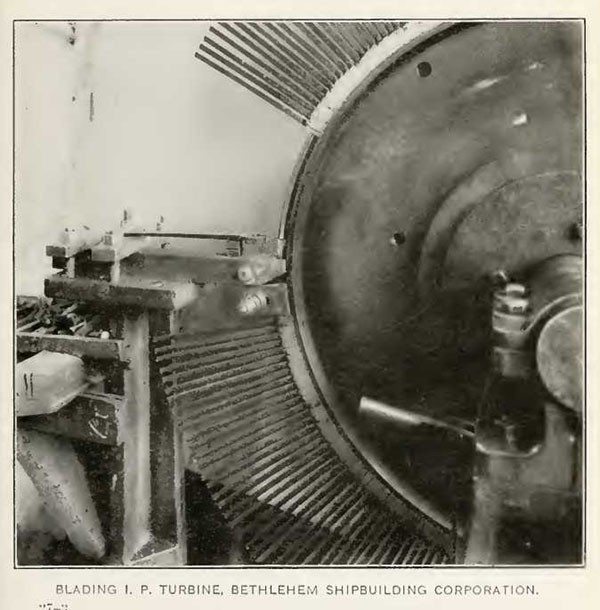

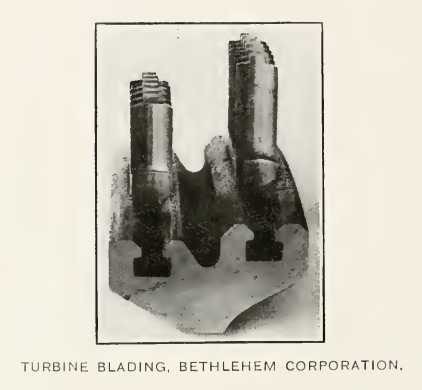

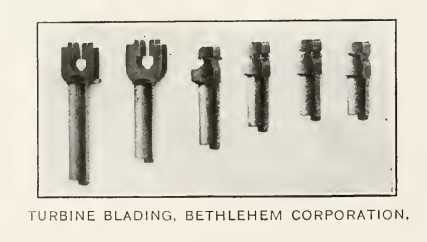

The act of August 20, 1916, authorized the immediate construction of 20 destroyers, the design of which had been well advanced at that date. The speed contemplated was 35 knots. This was an increase of 5 knots over that of preceding destroyers and involved the solution of many difficult problems before the design was finally determined upon.

The contracts for these 20 vessels were let in November and December, 1917, and were quickly followed by additional orders as fast as building facilities permitted, until a total of 270 were under order whose construction was authorized subsequent to August 29, 1916, and prior to October 10, 1917. Of this number the order for 120 had been given prior to the act of October 6, 1917.

As additional orders were placed from time to time, propositions were made to build 30-knot and also 28-knot destroyers, all with a view to increasing production; but as the design of those under construction was well standardized this Bureau insisted upon adhering to the 35-knot boat as involving the least element of delay. When, however, in July, 1917, the Bethlehem Shipbuilding Corporation submitted a tentative proposition for the construction of 150, serious consideration was given to the adoption of a 28-knot boat, as Admiral Sims had reported that any speed in excess of 25-knots would be satisfactory. The 28-knot speed was considered from the fact that the destroyers under contract could make that speed with two boilers instead of four. After closer investigation, however, it was found that the construction of boilers was not the time-controlling factor, and in general consideration of the subject several conferences were held with shipbuilders and manufacturers of forgings, boilers, machinery, and equipment, at which all phases of the problem were discussed.

As a result of these conferences it was determined that the most difficult situation to be faced was the one of forgings for shafting. For 28-knots solid forgings could be used and forging facilities utilized which would not be available if hollow forgings were insisted upon. There were only two large forging establishments

--25--

that could handle all the material that would be needed tor 35-knot vessels, and a third that could make only the shaft forgings; but the two firms with facilities for making all the forgings were not keen to undertake their manufacture. Both had large munition orders and preferred to continue that class of work. In fact great difficulty had been experienced in getting one of the companies to supply the forgings for which they had contract, for the destroyers building at Cramps and at the New York Shipbuilding Co., and it required some decisive action on the part of the chairman of the War Industries Board before the prompt completion of these contracts was assured. As it was contemplated to build the 150 destroyers in 18 months, it was clear that additional forging facilities would have to be provided to carry out this program.

The proposition submitted by the Bethlehem Shipbuilding Corporation contemplated the erection of a turbine building shop at Buffalo, a boiler shop at Providence, and extensions of the works of other firms closely affiliated with the successful completion of this unprecedented undertaking. It was apparent that Bethlehem could not handle the entire number of vessels, and equally so that, if completed at all, the work would have to be done by those firms that were then building destroyers, and whose organization and experience were such as to justify confidence in the successful completion and operation of the vessels assigned them. But every one of these establishments was working to full capacity, and some of them were subletting important portions of the machinery which ordinarily are completed in their own shops. In some cases, these subcontracts were given to people who were unfamiliar with the class of work they had undertaken, and this resulted in a reduced output from the scheduled requirement. No assistance could be expected from other shipbuilders of experience, as they were fully occupied with merchant work and with mine sweepers.

After full consideration of all the difficulties that had to be overcome, the Department decided to ask authority of Congress to build 150 additional destroyers. This authority was granted in the act of October 6, 1916, and the distribution was made as follows:

85 to Bethlehem Shipbuilding Corporation, of which 45 were to be built at Quincy and Squantum, Mass., and 40 at the Union Iron Works, San Francisco, Calif.

25 to the William Cramp & Sons Ship and Engine Building Co.

20 to the Newport News Shipbuilding & Dry Dock Co., Newport News, Va.

20 to the New York Shipbuilding Corporation, Camden, N. J.

Later on six more destroyers were assigned to the Mare Island Navy Yard and three to the Norfolk Yard. Six had previously

--26--

been assigned to Mare Island and one to Charleston. The first consideration in the design of the machinery was reliability coupled with speedy construction, and next to that was simplification of design in order to meet the condition that was fast confronting us of a very much lower standard of efficiency in both commissioned and the enlisted personnel. The destroyer force, as it existed in April, 1917, had most efficient personnel, and the encomium heaped upon their performance bore ample testimony to this happy condition. As additional destroyers were built, the majority of the crews had, of necessity, to be made up of inexperienced men. and everything that was possible was done to make the machinery installation simple and easy of operation.

Standardization, where possible, was insisted upon and successfully accomplished with propellers, propeller shafts, turbine units, pumps, blowers, safety valves, evaporators and distillers, ice machines, electric generators, searchlights, and even in smaller details. Much credit is due the shipbuilders, who set aside many of their own standards in order to cooperate fully with the Bureau in reducing the number of types to a minimum.

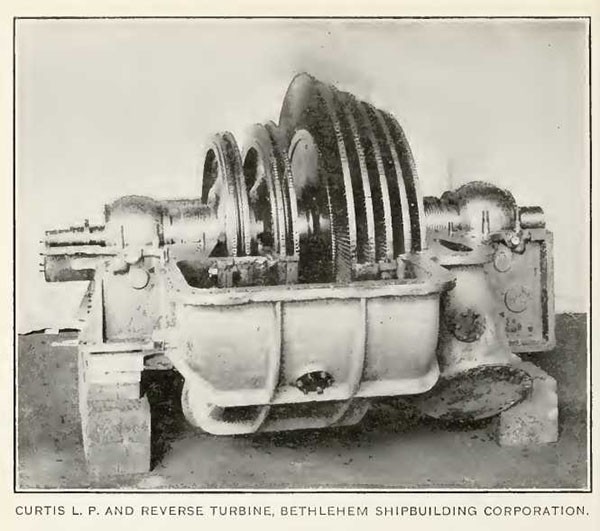

The 45 destroyers assigned to be built at Fore River and at Squantum—which latter place, in the language of the architect of the buildings, existed originally only as “a good marsh”—were to be duplicates of other destroyers building by Bethlehem. The engines for some were to be constructed at Fore River, but the majority were assigned to the new shop at Buffalo, the erection of which proceeded under great difficulty on account of the unprecedentedly cold winter of 1917-18. So far as concerned machinery, Squantum was simply an assembly plant. The castings for the turbine casings were made at other points and shipped to Buffalo. About two-thirds of the boilers for the entire lot were built in the new shop at Providence, which was specially equipped for the manufacture of Yarrow boilers, and the remainder at Quincy.

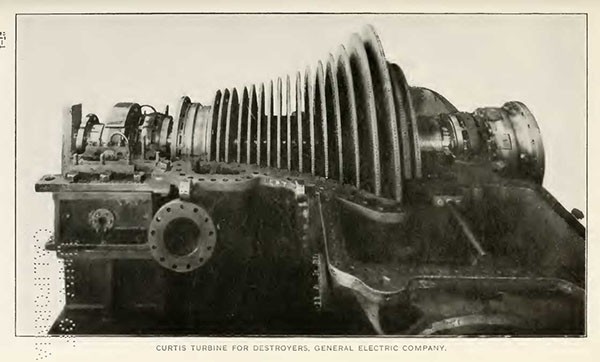

In the case of the Union Iron Works destroyers, a new shop had been erected at Alameda in order to facilitate the construction of the destroyers already under contract, and it was hoped that this shop would also be able to handle the machinery of the 40 additional destroyers, but it soon became apparent that this source of supply could not be depended upon. Fortunately, the General Electric Co. had just completed at Erie, Pa., the erection of a building which would admirably serve the purpose of a turbine shop, and a contract was accordingly entered into with them for equipping the shop and for building the turbines for the entire lot of 40 destroyers. It is of interest to note that the order for this work was given 10 days before Congress authorized the construction of these vessels.

--27--

In order to make possible the construction of the boilers at San Francisco, it was necessary to rent for this purpose the old Risdon Iron Works, and to equip and incorporate it as a part of the Union Iron Works. All the boilers were of the Yarrow type.

The turbines for the Cramp destroyers were built by that company, and this construction was made possible only by the purchase on account of the Navy Department of the stock of the De La Vergne Machinery Co., of New York City, and of the transfer of the operation of the works to the Cramp company. For the turbines for the Newport News and the New York Shipbuilding Corporation destroyers, a contract was entered into with the Westinghouse Machinery Corporation, which sublet a large portion of the work to the Allis-Chalmers Co. Thus were enlisted the combined facilities of those two big engineering establishments in the production of these engines. The Newport News Co. had, in the case of previous destroyers, found it necessary to place contracts for important portions of the turbines with firms in the Middle West, but the results that had attended the production of this work had not been of such a character as to justify an extension of these contracts, and for that reason the last 20 destroyers built by this firm, as well as those built by the New York Shipbuilding Corporation, have turbines differing from those of preceding ones.

The Bath Iron Works was not assigned any of the last 150 destroyers, as they were fully occupied with the orders in hand at the time the new destroyers were authorized.