The Navy Department Library

Descriptive Guide of the US Navy Yard, Washington, DC

HISTORY

AND

DESCRIPTIVE GUIDE

OF THE

U.S. NAVY YARD,

WASHINGTON, D.C.

-------------------------------------

COMPILED BY

F. E. Farnham and J. Mundell.

--------------------------------------

WASHINGTON, D.C.:

GIBSON BROS, PRINTERS AND BOOKBINDERS.

1894.

--------------------------

Copyright, 1894, by F. E. Farham and J. Mundell.

-------------------------

NAVY YARD, WASHINGTON, D.C.

--------------------------

A Brief History of the Navy Yard from its Foundation

in the Year 1799 to the Present Time.

-------------------------

Shortly after the close of the administration of John Adams, the second President of the United States, a great national exigency arising from the French aggression upon our commerce, assisted by an eloquent appeal of Benj. Stoddard to the House of Representatives, induced Congress, on the 25th day of February, 1799, to make an appropriation of $1,000,000 for the building of six of the largest ships of war. That the object of this appropriation should be more speedily accomplished, together with the design of creating a permanent navy, the Navy Department, in the latter part of the year, proceeded to apply a portion of this appropriation to the purchase and improvement of selected grounds for six navy yards, located as follows: One at New York, N.Y.; one at Philadelphia, Pa.; one at Boston, Mass.; one at Portsmouth, N.H.; one at Norfolk, Va., and one at Washington, D.C. The grounds comprising the Washington Navy Yard were originally purchased for $4,000, and consisted of forty acres of rolling land lying on the “Eastern Branch” of the Potomac River. This yard was originally designed as a ship-building and dock yard, but has now been turned into an ordnance factory, only one ship having been built here since the late war. Under the command of Capt. Tingey the Yard progressed rapidly, becoming a centre and depot of supplies from which our ships and other navy yards received their stores until it was destroyed by fire upon the

4

approach of the British forces under General Ross on the 27th day of August 1814, and it was not until the next year that Congress appropriated money for the rebuilding of the Yard, but the work was pushed rapidly and by fall of 1816 it was in good running order again. The work of increasing the capacity of the Yard continued from year to year until the beginning of the rebellion, when it was taxed to its the utmost capacity in the manufacture of ordnance and ordnance store, also as a repair shop in which vessels that were disabled were repaired and refitted. Since the war it has been gradually declining in importance as a ship yard, but the ordnance department has in the meantime held its own, and at intervals - “unhappily interrupted, however, by delay and inaction” - it has made rapid advancement and now contains the finest equipped gun shop in the world. By order of Secretary Whitney, on April 14, 1886, the Yard was transferred from the Bureaus of Construction and Repairs, Steam Engineering, and Yards and Docks to the Bureau of Ordnance, with all buildings and machinery, so that an ordnance factory equal to the demand of the times and capable of supplying our new ships of war with guns which in power and efficiency will at least be equal to those of other advanced nations has grown up. The estimated cost of the entire gun plant and appurtenances is about $2,000.000. From the time of its organization to the present time it has been commanded by thirty-three of our country’s distinguished naval officers, the streets and avenues of the Yard having been named after them. The present Commandant is Capt. Howell, who took charge on the 8th day of February 1893.

GUIDE TO THE YARD.

The building over the entrance to the Navy Yard is the Marine Barracks, in which are the quarters of the men who are stationed here on shore duty as guards. On entering the Navy Yard you are on Dahlgren avenue, which runs through

5

the centre to the Commandant’s office, thus affording a direct view of this portion of the Yard. To the left is the Commandant’s residence, with that of Superintendent of the gun factory a little further down. The first objects of interest to visitors are the two old-fashioned, muzzle loading bronze cannon mounted on either side of the avenue. They were made in Barcelona, Spain, in 1788, and were captured from the Tripolitans by Capt. Stephen Decatur on the 3d day of August, 1804. Next is the flag-staff and time bell, the time of the day being struck every half-hour during the twenty-four. The flag is raised at 8 A.M., “Colors,” and lowered at sunset, or “Retreat.” Watch-box No.1, from which any information pertaining to the Yard or shops may be obtained, is on the right hand. Further down, at the head of the iron railing, you will find a small stairway which will take you to the entrance of the gun shop. On entering the gun shop keep to the right. Lathe No. 1 is the lathe on which the rifling of the larger guns is done. This is the process of cutting small grooves in the barrel of the gun, the same having a twist of one and half times in the entire length of the gun, thus turning the shell when it is fired, keeping it straight on its course and point foremost. Between lathes Nos. 1 and 2 is the lapping machine for smoothing and polishing the interior of the gun, a heavy piece of lead conforming to the size and shape of the bore and which is drawn back and forth through the rifled portion with a mixture of oil and fine emery. Lathe No. 2 is the largest one in the shops and is commonly called the 16” lathe, as it was built for turning out a gun 16” in diameter of barrel, 48 feet 7 inches long, and weighing 110 tons. This size, however, was found too large for practical use, a smaller calibre being just as efficient and much easier handled. The largest gun now made in the United States for the Navy is the 13” gun. The lathe is now used for boring the interior of the tubes, for, when they arrive here in their rough state, they are about two one-

6

hundredths of an inch too small. This lathe is about 115 feet long and cost nearly $100,000. No. 3 is used for the boring of 10” and 12” tubes and is about twenty feet shorter than No. 2. No. 4 is used for turning and shaping the outside of the larger guns, some cuts being made as fine as one one-hundredth of an inch. Nos. 5, 6, 7, 8, and 9 are used during the different stages of construction of the 8”, 10”, 12”, and 13” guns. The power for these first nine lathes is furnished by a 250 horse-power compound Armington and Sims engine, the transmission of the power from the engine to the pulleys being by rope instead of belting. Within the same enclosure as the engine is a hydraulic pump similar to the ones used on board the new ships for working the great guns. Traveling over these lathes, 40 feet from the floor, is a mammoth crane, capable of raising and carrying from one lathe to the other 125 tons as easily as you or I could a ten-pound weight. On either side of this part of the shop, “which is called the north gun shop,” is a gallery in which some of the different parts of breech mechanism are made. In the centre of this building is the shrinking pit, in which the furnaces are located for heating the jackets and hoops preparatory to shrinking, starting with the tube, over which goes the jacket, jacket-hoops, and chase hoops, these being dressed down each time, by the lathes which you have just passed, to allow the next piece to fit over it. After cooling, these parts fit as closely as though they had been cast solid, but their being put together in this way gives greater elasticity and strength to the gun.

There are three furnaces in the pit, one at either end for the smaller pieces and one in the centre for the largest jackets and hoops. These pieces are placed in the furnaces and heated for a period of from an hour and half to thirty hours, according to the size, with the furnace heated to between six and seven hundred degrees, the heating power being naphtha oil with an air blast.

7

The south of the gun shop is just a repetition of the north, excepting in the size of the lathes and size of guns made; the 4, 5, and 6 inch and other smaller guns are finished at this end. After going out the east door, “which you will see to your left a short distance beyond the shrinking pit,” is an old gun which was made in 1786, and is the original Long Tom, one of the guns of the famous private armed brig General Armstrong, commanded by Captain Samuel Chester Reid. The remarkable heroism of Captain Reid and his officers and men is conspicuous in the history of our country. In a conflict with a British squadron mounting 136 guns and about 2,000 men, this gun did such admirable execution that the British lost over 300 men and officers killed and wounded. The Armstrong carried but 7 guns and 90 men, and lost but two killed and seven wounded. The battle took place at Fayal, one of the Azore Islands, on the 26th day of September 1814. The disabling of the squadron, which was a part of the expedition against New Orleans, so delayed the fleet that it saved Louisiana from British conquest. This gun was presented to the United States by the Portuguese Government, and was forwarded from Fayal to the World’s Fair, where it was on exhibition as part of the Navy Department’s exhibit. After the fair it was brought to this yard and mounted where it now stands.

Below this is the fire-engine and hose-carriage house, both of which, upon the alarm of fire being sounded, are manned by marines who are stationed in the barracks at the main gate.

Passing down the avenue to the next intersecting street, you will see in front of the Commandant’s office several trophies, the largest ones on either side of the steps having been captured by Captain Stephen Decatur from the Tripolitans during the year 1814. In passing around to the left of this building you will see a large ship-house, which is used as a marine railway for the repairing of small vessels. To the

8

rear of the Commandant’s office is the gun park, in which are the trophies captured during the war of the Revolution, war of 1812, war of 1847 with Mexico, and the war of the Rebellion.

After leaving the gun park, cross over to the gun-carriage shop. This is the shop in which the gun mounts and the gun carriages are built. The castings are brought here in their rough state, then tested and inspected; the ones passing are then turned over to the workmen to be finished, the ones rejected are returned to the contractor, each piece going through the necessary machining, after which they are turned over to other workmen, who put them together. Each gun carriage is completed and tested before it leaves the shops. Nearly all the larger guns are worked by hydraulic pressure, thereby making it possible for one man to move the largest gun. The old-style muzzle-loaders required a gun’s crew of from 14 to 24 men, the gun sliding back across the deck when discharged, and the recoil being taken up by the heavy hawsers which were fastened to the ship’s sides. The recoil of the modern guns is taken up in hydraulic cylinders, which are on the gun carriage in the 6, 8, 10, 12, and 13 inch, and on the 4 and 5 inch are screwed to the gun forming the trunnions, with which the gun is secured to the carriage.

At the north end of this shop the small rapid-fire gun carriages are assembled. Passing out the north door of this shop you turn to your left and pass down the street to the next intersecting one, cross over and enter the breech mechanism shop, in which the fine and delicate work is done; the breech mechanism of nearly all the guns is made and put together in this shop; the delicacy of this work can be imagined when we say that a jeweler does not have to be more exact in fitting the different parts of a watch than these workmen do the different parts of breech mechanism for the guns.

Leaving this shop by the same door through which you entered, turn to the building on the left, which is the pro-

9

jectile shop, in which shells are made and finished. These shells are furnished by contract, several shells being selected from out of a lot of about 100 and fired at steel plates; if they withstand the shock at striking, without breaking up, the entire lot is accepted; if they fail the lot is rejected. These shells are all electric welded. After arriving at the yard, there is a groove from ¾ inch to 2 inches wide by about 3/8 inch deep, “according to size of shell,” cut out near the seat of the shell, into which is forced a copper band by hydraulic pressure; the shell is then placed in a lathe, the copper band being turned down nearly to the size of the shell. The object for which this copper band is placed on the shell is to give a rotary motion to the shell and to preserve the rifling of the gun, as the hard steel would in a very short time wear this out, thus spoiling the gun. On leaving this shop you continue on up the street to the museum, on the outside of which you will see a lot of shot and shell of various forms and shapes that were captured from the Confederates during the late war; also a large willow tree; the slip from which it started was cut from a tree over the grave of Napoleon at St. Helena, and was brought here by Commodore Bainbridge. On entering keep to the right and follow the numbers as found in this catalogue.

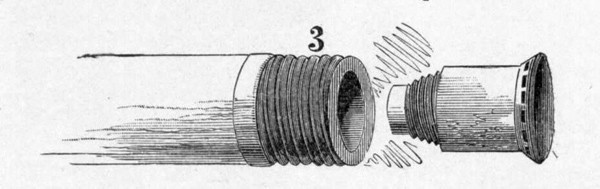

CATALOGUE OF THE MUSEUM

Article 1 is breech-loading gun made in Spain in the year 1490, brought over by General Cortez during the conquest of Mexico, and captured by Captain Hunter, U.S. Navy, during the Mexican War.

Case 1 contains specimens of shell cut in half to show interior. On the shelf above are models of different types of guns and gun carriages.

Article 2: Two small boat swivels made in 1858, in this yard, and used by the survey expedition of Lieutenant Brooks in the Pacific.

10

Article 3: Revolving cannon patented in 1861 by the J. A. De Brame, which proved a failure on account of perforated barrel.

Article 4 is a torpedo similar to the one used by Lieutenant Cushing when he sunk the Albemarle.

Case 2 contains old torpedoes, samples of iron and iron ore, percussion and time fuse, rockets and signal lights and friction and percussion primers; also three swords captured on the Confederate steamer Florida at Bahia, Brazil.

Article 4: Small breech-loading rifle gotten up by T. B. Floyd while Secretary of War.

Article 5: Statute of Admiral Farragut.

Racks 1 and 2 contain English, French, Austrian, and American makes of guns.

Article 6: Dahlgren boat-howitzer.

Case 4 contains different styles of shot and shell.

Article 7: Part of the stern post of the Kearsarge, which was struck by a shell weighing 55.75 pounds during the engagement, off the coast of Cherbourg, France, with the Confederate steamer Alabama; it is the original shell which you see lodged there, it having failed to explode.

Article 8: A repeating swivel flint-flock made in 1814; it has seven barrels, which will hold about 80 charges; first one is fired by the flint, which ignites a port fire in the centre barrel, thus exploding each charge as fire reaches it.

Case 5 contains old paper cartridges, minnie balls and prepared ammunition, prismatic powder in octagon blocks, and an old gun found while dredging in 1884; it was on the U.S.S. Argus, which was burned at the approach of the British, August 27, 1814.

11

Case 6 contains a lot of shot and shell, some of which have been exploded; also a model of a submarine gun that was intended for the torpedo-boat Destroyer, which was built by Ericcson and was sold to the Brazilian Government during their civil was in 1893; it was renamed the Paratinus.

Rack 3 contains different styles of rifles and carbines; also a single-barrel repeater, holding five shots, which has sliding lock and was invented in 1825.

Article 9 is a machine gun invented by E. Nugent in 1861; was called the coffee-mill gun.

Article 10 is a charge of grape shot for 15-inch smooth-bore gun and is composed of nine 32-pound shells.

Article 11 represents a full charge for a 10-inch breech-loading rifle.

Article 12 represents a full charge for an 8-inch breech-loading rifle

Rack 4 contains:

1. Flint-lock musket.

2. Flint-lock changed to percussion.

3. Old-time Springfield rifle with rear sight.

4. Old flint-lock revolver made in England in 1793.

5. Colt’s revolving rifle, old style.

6. Hall’s breech-loading rifle, made in 1832.

7. Sharp’s breech-loading rifle, made in 1848.

8. Remington breech-loading rife, made in 1860.

9. Evans’ magazine rifle, holding 32 cartridges in the stock; was made in 1868.

10. Henry magazine rifle, which holds 16 cartridges and is similar to Winchester, made in 1860.

11. Spencer magazine rifle, which holds 8 cartridges and was made in 1840.

12

12. Lee magazine rifle, which holds 5 cartridges. This is the rifle that is now used in the U. S. Navy; 20 shots can be fired in 30 seconds with accuracy.

On top of the heater are various styles of shot and shell, grape shot, chain shot, canister, and hand-grenades; also two swivel blunderbusses captured from Mexico in 1847; also the bust of Hotchkiss, the inventor of the Hotchkiss guns.

Article 13: A small brass cannon captured from the Mexicans in 1847.

Case 7 contains models and relics, pieces from the Egyptian Obelisk which was recently erected in Central Park, New York, and was built 22 years before Christ; also a walrus tusk which was brought from the Artic Ocean by one of the Greeley relief expedition.

Case 8 contains samples of shot, shell-grape, and canister.

Article 14: Under case No. 7 is a model of a submarine rocket charged with compressed powder which propels it through the water, with a torpedo attached.

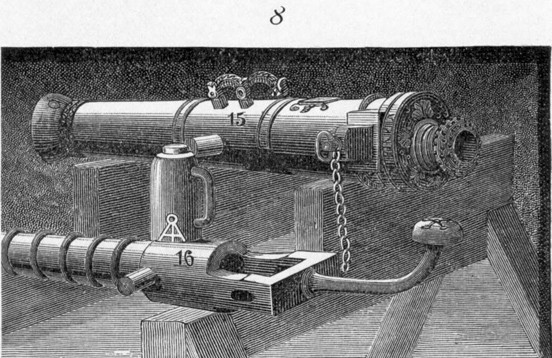

Article 15: Experimental 3-inch breech-loading rifle.

Article 16: The Lowell battery gun, which is capable of discharging 500 shots per minute; patented in 1867.

Article 17: A telescope rifle with several rings in front of the muzzle, which are intended to condense the smoke so as to deceive the enemy as where the shot comes from.

Article 18: Small brass gun captured from the Mexicans, which was made in 1773.

Rack 5: A collection of small-arms starting from the year 1793 to the time of the Civil War.

13

Article 19: Two small pistols captured on the Confederate steamer Florida.

Article 20: Small pistols which was on the U.S.S. Cumberland when she was sunk in Hampton Roads, Va., by the Confederate Steamer Merrimac.

Article 21: is a 15-inch shrapnel. Shrapnel was invented by an artillery officer in the year 1573; is a hollow shell filled with lead or iron bullets; this shell explodes at about 300 feet from the gun and scatters the contents in every direction. The shrapnel of to-day is an elongated shell which contains a large charge of powder in the bottom and is fired by a fuse, which explodes immediately upon striking.

Article 22: Billinghurst battery; has 25 barrels, which are discharged at one time; it is loaded at the breech; was made in 1862.

Article 23: Small brass mortar made in Philadelphia in 1793.

Article 24: Small brass mortar; was taken from Lord Cornwallis at the surrender of Yorktown, 1781.

Article 25: Two boarding helmets used in the Navy during the war of 1812.

Rack 6 contains carbines and Navy cutlasses.

Article 26: One of the first Gatling guns, invented by Dr. Gatling in 1862, which fires about 300 shots per minute. The improved pattern of 1884 will fire about 1,200-four times the number of the first one.

Article 27: Three small flint-lock swivels captured from the Mexicans in 1847; were made in the 18th century.

Article 28: Model of turret for monitor, an improvement on the old style; has two walls which deaden the concussion.

14

Article 29: torpedo shell for protecting harbor obstructions.

Article 30: Sailor of the U.S. Navy showing uniform of the year 1800.

Case 9 contains:

1. Shell fired from one of the Confederate steamers, which lodged in the headquarters of General Mansfield, during an attack on the frigates Congress and Cumberland, off Newport News, Va.

2. Shell fired into the U.S.S. Yankee off Cockpit Point, Va.

3. Shells taken out of Confederate magazine at Roanoke Island.

4. Chevaux-de-frise for obstructing rivers and harbors.

5. A spike, called a Yankee sinker, taken from one of the rivers of North Carolina.

Case 10 contains models of guns and gun carriages, torpedoes captured from the Confederates, Whitworth and Armstrong shell.

Article 31: Small brass gun made in the 16th century; was captured from the Tripolitans in 1804 by Captain Stephen Decatur.

Case 11 contains models of guns, gun carriages, and gun locks for discharging old style muzzle-loaders; also shot and shell of various types.

Article 32: First brass 12-pounder howitzer; was cast by Admiral Dahlgren at this yard in 1848.

Article 33: An electric torpedo captured from the Confederates in 1864 by the Potomac flotilla under Capt. Hooker, U.S. N.

15

On leaving the museum turn to your left and continue on up the street to the main gate, this being the only exit for visitors. The houses you pass are occupied by the officers, and their families, who are connected with the Yard, each officer having charge of a certain branch of work, for which he is responsible.

16

It is indeed an extraordinary fact that the first guns of which we have any authentic record were breech-loaders. The breech-loading gun has passed through a period of desuetude, but to-day it stands without a rival and is truly the survival of the fittest. There is hardly a single principle of the modern breech-loading or machine gun which was not in use before 1700, and many of these principles are two hundred years older.

Tradition has named the battle of Crécy (1346) as the first occasion on which the weapon that was to revolutionize the art of war was used; but it is very probable that the use of cannon antedates the battle of Crécy by several years. Many historical works have stated that the battle of Crécy was won chiefly through the agency of a few small cannon; but this is very improbable, as the battle of that period was practically a succession of duels in which the individual was everything, and upon his valor in the hand-to-hand conflict the fate of the battle depended much more than in the modern long-range battles.

17

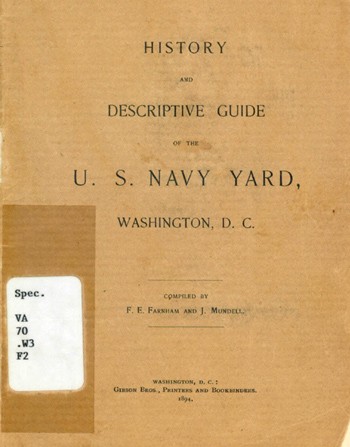

English cannon used at the battle of Crécy, which we illustrate in Fig. 1, were made of forged iron and were open at both ends. The breech was probably closed with an iron block wedged in. The cannon was bound and re-enforced by bands. The mounting of the gun was very crude and could hardly have permitted of much accuracy of aim. The early cannon were called bombardes and pierriers, the latter name being used because stones were frequently used in place of other missiles. A little later the nomenclature became involved in inextricable confusion and the same kind of cannon are often described in different localities as serpentines, coulverines, faucons, passe volants, basilics, spirales, and bombardes.

18

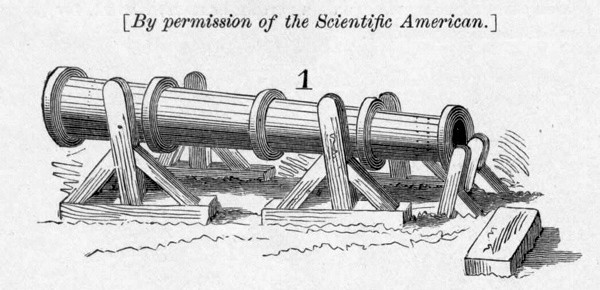

Fig. 2 shows a blind or mantlet to a breech-loading cannon known at the time as a schirmdach. The gun and its mantlet belong to the second half of the fourteenth century. The swinging contrivance was by no means new, as it was used in siege work from Roman times to protect the balista. The figures are accoutered in the armor of the period.

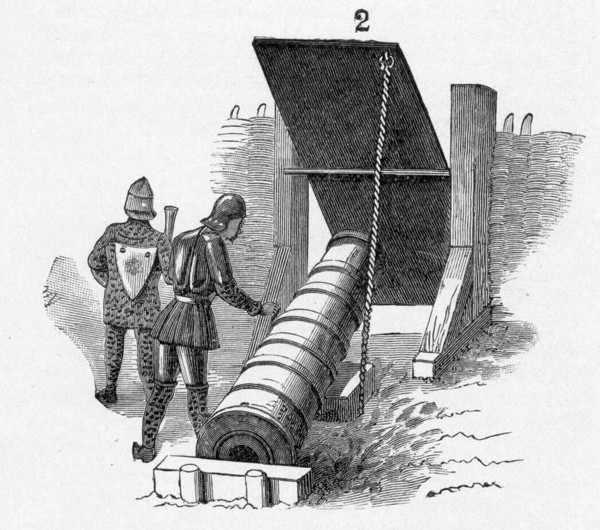

The next gun, Fig. 3, is a Flemish breech-loading cannon. This curious engine, whose fire chamber screws into the barrel, is of forged iron, and was made at Ghent between 1404 and 1419. Holes will be noticed on the end to allow of its being screwed up tight with a spanner. Thus we have the principle which is used to-day in many systems of ordnance.

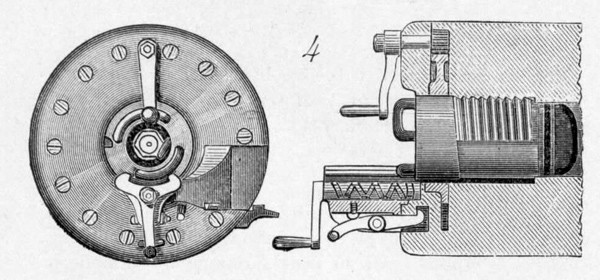

In Fig. 4, for example, is shown a piece of modern ordnance using a screw breech block almost exactly similar to this early piece.

19

Fig. 4 represents the regular arrangement of a rifled gun. The breech mechanism is regarded as being highly satisfactory. The breech block is provided with an interrupted screw for locking in the breech. One-sixth of a turn of the upper handle will lock or unlock the breech. A translating roller withdraws the block with great rapidity, as the screw thread is double. The block slides along the guide rails of the tray till the ends of these rails strike against the shoulders of the grooves. The shock due to this striking disengages a latch; the tray and block are then swung back to allow of the gun being loaded.

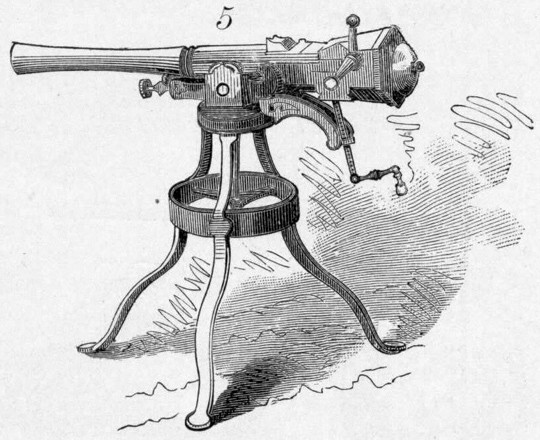

Fig. 5 shows a small iron breech-loading cannon on revolving gun carriage. This piece was left at Munich in 1632, by Gustavus Adolphus. All the usual adjustments in the modern machine guns were provided for.

The old manufacturers of ordnance at an early period saw the advantages of light rapid-fire guns and they produced some remarkable pieces.

20

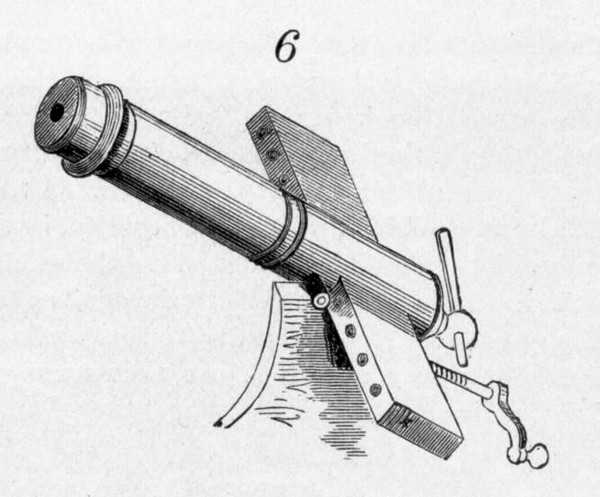

Fig. 6 shows a small Swiss copper cannon adapted for firing ten successive charges. The length of the barrel is 27 inches, and it bears the signature of Welten, the inventor, 1742.

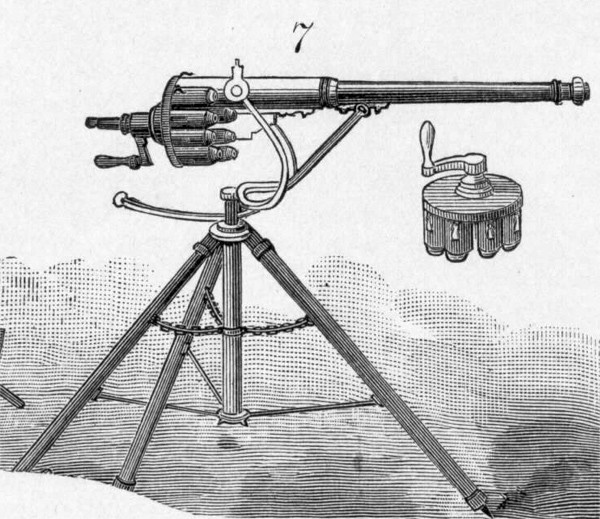

Fig. 7 is an interesting machine gun of 1718. Letters patent were granted to Mr. James Puckle for this gun.

21

The light gun with its folding legs, the universal adjustment and the “Sett of Chambers ready charged to be Slip’d on when the first Sett are pull’d off to be recharg’d,” is an extraordinary manifestation of the ability of our forefathers unassisted by Messrs. Nordenfelt, Maxim, Gardner, et al. In the quaint language of Mr. Puckle, the gun is intended for “bridges, beaches, lines, passes, ships’ boats, houses, and other places.” The claim of the inventor to universality of application would horrify a United States Patent Office Examiner of the present day. The method of manipulation will be readily understood by reference to the illustration, the successive charges being forced into the breech of the gun by a translating screw. The folding tripod and facilities for adjustment have been only very slightly improved upon in the nineteenth century. A set of chambers is shown at the side.

Fig. 8 shows a Dutch cannon made in 1650. The bore is continued through the cascabel, being closed at the breech after loading by a wedge moving horizontally, being on the same general principle as that of Krupp.

[22]

DESCRIPTION OF U. S. NAVAL MODERN ORDNANCE.

The guns constituting the main batteries of all vessels built or armed since the reconstruction of the navy was begun are steel breech-loading rifles. The calibres thus far manufactured are 4, 5, 6, 8, 10, 12, and 13 inch. The system of construction and the method of manufacture are the same for all these guns. Each gun is built up of a number of forged steel parts, the 4 and 5 inch being composed of a tube, jacket, and two chase hoops, and the larger guns having a third layer of jacket hoops and chase hoops, in some cases extending to the muzzle. These parts are assembled with shrinkage. The forgings used in the construction of these guns are made from open-hearth steel ingots cast solid and weigh about twice as much as the finished piece required. For hoops, and sometimes for jackets and tubes, the ingot is bored and then forged on a mandrel, otherwise it is forged solid. After forging the piece is rough bored and turned nearly to the finished dimensions, but enough metal is left on one or both ends to allow taking test specimens. The rough bored and turned forging is then annealed, tempered in oil, and again annealed, after which specimens are cut from the ends and broken in a testing machine. If these tests conform to the requirements in tensile strength, elastic limit, and elongation, the forging is then accepted.

Each forging is stamped with the calibre and part of the gun, its own distinctive number, and the initials of the Government inspector.

The machining and assembling of the forgings is done at this place, and all the guns thus far, with the exception of the twenty-three 6-inch and four 8-inch, made by contract, have been constructed here. The general process is as follows:

23

The complete set of forgings for a gun having been accepted, the shrinkages are calculated, using the lowest elastic limit shown by any specimen from each forging as the basis of the computations. The jacket forging is bored to the required diameter, and is then carefully star-gauged. While this is being done, hoops are also finished, bored and faced, and then star-gauged.

The hoop is first bored out nearly to finished size and is then turned to a diameter at each point exceeding the interior diameter of the jacket at the corresponding point by the assigned shrinkage. The tube is then placed vertically in the shrinking pit, and the jacket having been expanded by heat, is lowered down over it and then allowed to cool.

The assembled tube and jacket are then placed in a lathe and the tube is turned to the proper diameters for the chase hoops, which are put on successively, each with its assigned shrinkage, after which the jacket is turned for the jacket hoops, and they are put on in the same manner. The gun is then finished-bored, the chamber is bored out, the screw box is threaded, and the exterior is finished-turned. Whenever, in machining, it is necessary to cut away the marks on a forging, they are transferred to another part of the piece, so that in the finished gun each piece can be identified. Finally the gun is rifled, the screw box blanks are planed out, the breech mechanism is fitted, the gun is sighted, and after proof-firing at the proving grounds at Indian Head, Maryland, about 30 miles below Washington, on the Potomac river, is ready for issue to the service. Guns of each calibre are numbered consecutively from number one, and the different designs of each calibre are distinguished by the mark I, II, III, IIII, and so on, a new mark usually indicating a considerable change in the construction of the gun. The calculated elastic strength of these guns over the chamber ranges from 18 to 24 tons per square inch, but pressures as high as 30 tons per square inch have been

24

measured in powder tests and no permanent enlargement of the gun has subsequently been found. For service the chamber pressure is limited to 15 tons per square inch, as the lifetime of the guns is greatly decreased by the use of excessive pressures, the main cause of deterioration being the erosive action of the powder gases near the seat of the projectile. For the same purpose of lengthening the gun’s lifetime, and for economy, all except the rapid-fire guns are supplied with reduced charges, of about three-fourths of the weight of a full charge, for use in target practice. The muzzle velocity given by this reduced charge is 1,700 foot-seconds in guns of 30 calibres length of bore, compared to 2,100 foot-seconds for full charge, and the sights are marked for this, as well as the full-charge velocity. What the actual life of the new naval guns will be can only be estimated, but there is a good reason to suppose that, for the smaller calibres at least, it will be equal or exceed that of the old cast-iron smooth-bores.

4-INCH BREECH-LOADING RIFLE.

Each gun is composed of five parts-tube, jacket, A-hoop, B-hoop, and breech plug. The A-hoop is put over the jacket with a reverse cone and thus locks the tube into the jacket. The 4 inch guns are trunnionless, but being held in the gun carriage by the projecting sides of the bronze sleeve or the band that screws onto the gun. The recoil of the gun when discharged is taken up in the hydraulic cylinders beneath the gun. The rifling consists of 30 equal grooves 0.025 inch deep. The muzzle velocity given by the full charge of brown powder is 2,000 foot-seconds.

Weight of gun, 3,400 lbs.

Weight of charge of brown powder, 13.5 lbs.

Steel which shell will perforate at 1,000 yds., 7.2 in.

Steel which shell will perforate at 2,000 yds., 4.2.in.

Weight of projectile, 33 lbs.

Range in miles, 4.

25

5-INCH BREECH-LOADING RIFLE.

Is composed of 14 principal parts-tube, jacket, A 1, A 2, A 3, B, C, D, E, F, and G hoops, trunnion bands, breech plug, and elevating band.

Weight of gun, 6,190 lbs.

Length of gun, mark I, 162 in.

Length of gun, mark II, 206 in.

Steel which shell will perforate at muzzle, 8.7 to 9.4 in.

Steel which shell will perforate at 2,000 yds., 5.5 in.

Muzzle velocity, 2,000 foot-seconds.

Weight of projectile, 50 and 60 lbs.

Weight of full charge brown powder, 26 to 29 lbs.

Range in miles, 5.

6-INCH BREECH-LOADING RIFLE.

Is composed of a tube, jacket, 15 hoops, a trunnion band, breech block, and elevating band. The rifling consists of 24 equal grooves, each 0.05 inch deep.

The weight of 6-inch gun, from 10,775 to 13,370 lbs.

Length, according to mark, from 189.7 to 256 in.

Weight of full charge of brown powder, 47 to 49 lbs.

Weight of reduced charge of brown powder, 34 to36 lbs.

Velocity at muzzle, 2,000 to 2,150 foot-seconds.

Steel which shell will perforate at 1,000 yds., 8.44 to 9.36 in.

Steel which shell will perforate at 2,000 yds., 6.89 to 7.64 in.

Weight of projectile, 100 lbs.

Range in miles, 6.

8-INCH BREECH-LOADING RIFLE.

Is composed of a tube, jacket, 19 hoops, trunnion band, breech block and elevating band. The rifling consists of 32 equal grooves of 0.05 inch deep.

Weight of gun, 27,600 lbs.

26

Weight of full charge brown powder, 105 to 115 lbs.

Weight of reduced charge of brown powder, 75 to 85 lbs.

Weight of projectile, 250 lbs.

Length, according to mark, from 304.50 to 357.99 in.

Velocity at muzzle, 2,000 to 2,150 foot-seconds.

Steel which shell will perforate at 1,000 yards, 12.63 to 14 in.

Steel which shell will perforate at 2,000 yards, 10.94 to 12.12 in.

Range in miles, 8.

10-INCH BREECH-LOADING RIFLE.

These guns are mounted in pairs in turrets, and are now used on the monitors Terror, Monadnock, Amphitrite, and Puritan, and on the battleships Maine and Texas, and on the barbette-turret coast-defence vessel Monterey.

The rifling consists of 40 equal grooves, each 0.05 inch deep.

Weight of gun, from 57,500 to 63,100 lbs.

Length of gun, 329.10 to 365.60 in.

Weight of full charge brown powder, 225 to 250 lbs.

Weight of reduced charge of brown powder, 170 to 190 lbs.

Weight of projectile, 500 lbs.

Velocity at muzzle, 2,000 foot-seconds.

Steel which shell will perforate at muzzle, 18.75 to 19.56 in.

Steel which shell will perforate at 2,000 yards, 15.03 to 15.65 in.

Range in miles, 10.

12-INCH BREECH-LOADING RIFLE.

These, same as the 10-inch, are mounted in pairs in a revolving turret.

The rifling of the 12-inch guns consist of 48 equal grooves, each 0.05 inch deep.

27

Weight, 101,300 lbs.

Length, 441 in.

Weight of full charge brown powder, 410 to 430 lbs.

Weight of reduced charge of brown powder, 310 to 330 lbs.

Steel which shell will perforate at muzzle, 24.16 in.

Steel which shell will perforate at 2,000 yards, 20.003 in.

Range in miles, 12.

13-INCH BREECH-LOADING RIFLE.

There is but one mark of the 13-inch guns, of which only twelve are to be made; these twelve are to be mounted in pairs aboard the U.S.S. Indiana, Massachusetts, and Oregon, four of which are to go on each ship.

The cost of these guns when completed is about $80,000 each, and it costs the Government nearly $1,000 each time one is fired.

The rifling consists of 52 equal grooves, each 0.05 inch deep; the twist of the rifling begins at zero and increases to one turn in 25 calibres.

Weight of gun, 136,000 lbs., or 65 tons.

Length of gun, 479.1 inches, or 39 feet 11 inches.

Weight of full charge brown powder, 520 to 560 lbs.

Weight of reduced charge of brown powder, 390 to 420 lbs.

Weight of projectile, 1,100 lbs.

Velocity at muzzle, 2,100 foot-seconds.

Steel which shell will perforate at muzzle, 26.66 in.

Steel which shell will perforate at 2,000 yards, 22.49 in.

Range in miles, 13.

[END]