The Navy Department Library

Submarine Report

Depth Charge, Bomb, Mine, Torpedo and Gunfire Damage Including Losses in Action

7 December, 1941 to 15 August, 1945

Volume 1

CONFIDENTIAL

Submarine Report

Depth Charge, Bomb, Mine, Torpedo

and Gunfire Damage

Including Losses in action

7 December 1941 to 15 August 1945

Volume 1

The Chief of Naval Operations directs that this report be shown only to those persons to whom the report would be of value in the performance of their duties.

Steps shall be taken accordingly to insure that the report will be seen by those persons responsible for design, construction and repair of naval vessels, as well as for their operation, but by no others.

Preliminary Design Section

Bureau of Ships

Navy Department

1 January 1949

WAR DAMAGE REPORT No. 58

Printed By U. S. Hydrographic Office

SUBMARINE REPORT

Depth Charge, Bomb, Mine, Torpedo and

Gunfire Damage

Including Losses in Action

7 December, 1941 TO 15 August, 1945

1 January 1949

APPROVED

C. L. BRAND

Rear Admiral, USN

Ass't. Chief of Bureau for Ships

| Page | ||||||

| I | FOREWORD | 1 |

||||

| II | GENERAL | 2 |

||||

| III | JAPANESE ANTI-SUBMARINE WARFARE AND WEAPONS | 8 |

||||

| Name | No. | Damaged by | Locale | Date | ||

| IV | PERCH | 176 | Depth Charge | Java Sea | 3/3/42 | 17 |

| V | KINGFISH | 234 | Depth Charge | Formosa | 3/23/43 | 26 |

| VI | TUNNY | 282 | Depth Charge | Palau Is. | 8/26/43 | 47 |

| VII | SALMON | 182 | Depth Charge | S.E. of Kyushu | 10/30/44 | 61 |

| VIII | GRENADIER | 210 | Bomb | Malaya | 4/22/43 | 82 |

| IX | SCAMP | 277 | Bomb | Mindanao, P.I. | 4/7/44 | 89 |

| X | TANG | 306 | Torpedo | Formosa | 10/24/44 | 109 |

| XI | BERGALL | 320 | Mine | Gulf of Siam | 6/13/45 | 125 |

| XII | GRAMPUS | 207 | Gunfire | Truk | 5/17/42 | 131 |

| XIII | GROWLER | 215 | Collision | New Britain | 2/7/43 | 137 |

| XIV | DRAGONET | 293 | Grounding | Kurile Is. | 12/15/44 | 148 |

| XV | BEHAVIOR OF UNDERWATER NON-CONTACT EXPLOSIONS | 161 |

||||

| XVI | HULL DAMAGE AND STRENGTH | 177 |

||||

| XVII | STABILITY, BUOYANCY AND FLOODING | 193 |

||||

| XVIII | SHOCK PROTECTION | 203 |

||||

| XIX | ENGINEERING NOTES | 213 |

||||

| XX | PIPING | 223 |

||||

| XXI | HABITABILITY | 233 |

||||

| XXII | SUBMARINE ESCAPE NOTES | 239 |

||||

| XXIII | CONCLUSION | 248 |

||||

| APPENDIX I | BRIEFS OF DAMAGE INCURRED BY U.S. SUBMARINES DURING WORLD WAR II. | 250 |

||||

| APPENDIX II | TABULAR SUMMARY OF U.S. SUBMARINE LOSSES DURING WORLD WAR II. | 296 |

||||

| APPENDIX III | MAP COVERING AREA OF PRINCIPAL U.S. SUBMARINE OPERATIONS. | |||||

SECTION I

FOREWORD

1-1. This report is one of a series of sixty-two war damage reports prepared by the Bureau covering damage received in action by vessels of the U.S. Navy during World War II. It is the only report of the entire series which deals with war damage sustained by submarines. The remaining sixty-one reports cover cases of significant damage incurred by surface vessels, and include many instances of torpedo damage which may be of interest to submarine personnel who desire information on the destructive effect of their principal World War II weapon, the torpedo.

1-2. As a group, U.S. submarines have established an enviable record in combat, not only in destruction inflicted upon the enemy but also in their ability to sustain severe attacks without themselves receiving serious damage. Although the basic operational characteristics of our submarines remained substantially unchanged throughout the war years, with the notable exception of considerably increased maximum allowable submergence depth for the SS285 and subsequent Classes, marked advances were achieved in practically every other aspect of submarine and submarine equipment design. Improvements in shock protection have resulted in submarines which are highly resistant to damage short of actual destruction of their pressure hulls.

1-3. It is the purpose of this report, by presenting case histories selected from the great volume of war experience, to illustrate the behavior of U.S. fleet type submarines in service during World War II when subjected to enemy attack, and in particular, to attack by non-contact underwater explosive charges since the Japanese anti-submarine forces employed the depth charge and bomb as their principal weapons. Cases of damage by mine, torpedo, gunfire and collision are also included. An effort has been made to present a comprehensive summation of the effectiveness with which our submarines withstood attack, the materiel and design weaknesses revealed by war damage, the damage control problems attendant upon flooding of intact spaces or derangement of vital systems and equipment, and the corrective measures taken to reduce the vulnerability of our submarines to damage. It is hoped that the information presented here will be of value to submarine operating personnel and submarine design, repair and outfitting activities.

1-4. No attempt has been made in this report to evaluate the operational and military characteristics of our submarines in the light of War experience other than by statements of fact when such characteristics were impaired through war damage, nor have casualties incident to normal service operations been discussed. Lessons learned through the recent CROSSROADS OPERATION, and their possible effect on submarine design, have not been included.

--1--

2-1. The evolution of submarine design in this country has been unlike that of other naval vessels in that the early development was carried forward by private citizens, rather than by the Navy Department. Although the HOLLAND, completed by the Holland Torpedo Boat Company in 1898, was commissioned as our first submarine in April 1900, and numerous submarines were purchased from private concerns and added to the fleet in subsequent years, it was not until 1914 that the construction of a submarine was undertaken by the government. This was the L-8, built at the Navy Yard, Portsmouth, N. H., to the design of the Lake Torpedo Boat Company. It was not until late in 1916 that a complete preliminary design was prepared by the Navy Department for a submarine, the S-3. Commencing with the same vessel, the Navy Yard, Portsmouth was entrusted for the first time with the development of the detailed working plans as well as the construction. From 1919 until 1931 all submarines ordered were built to plans prepared by Portsmouth. Thereafter, the Electric Boat Company has prepared the working plans for all submarines built by it, while the Navy Yard, Portsmouth has prepared working plans for practically all submarines built in government yards.

2-2. The fact that two design agencies have been engaged in the development of submarines has led, it is believed, to more rapid progress than would have been accomplished by either of these agencies alone. Although each of the design agencies is allowed considerable freedom in the development of the details of a design, control is maintained in the Navy Department by virtue of the fact that the preliminary designs are prepared in the Navy Department, the contract plans are prepared in the Department or by an agency of the Department, and all working plans are subject to its approval. Thus, the best features developed by either agency may be incorporated into the designs prepared by the other.

2-3. By the year 1902, practicable solutions for the basic problems of submarine design had been achieved, at least in principle: i.e., electric motor drive with storage battery power for submerged propulsion; internal combustion engines for surface propulsion; the self-propelled torpedo as a means of inflicting damage on the enemy; a crude periscope for taking surface observations while submerged; and a satisfactory means of obtaining submerged control through the use of hydroplanes and variable ballast tanks. Subsequent development has been in the direction of refinement of design of the submarine as a whole and of its component parts, improvement in military characteristics and changes in design to keep pace with changed conditions of employment, rather than in the direction of changes in basic principles. One major innovation was the change to double-hull construction to improve seaworthiness through increased reserve buoyancy. The M-1, completed in 1918, was the first submarine of this type.

2-4. Commencing with the BARRACUDA Class of 1924 and continuing through the end of World War II, all submarines built by the U.S. Navy, with the exception of the 800 ton-type submarines MACKEREL (SS204) and MARLIN (SS205) completed in 1941, were of the fleet type, designed for high surface speeds and capable of operating for extended periods at sea and covering great distances. The submarine war effort of the United States was dependent almost entirely upon these fleet type submarines and for this reason only the damage experiences of fleet type submarines have been included in this report.

2-5. It is pertinent to mention that only negligible war experience was gained by our submarine service during World War I.1 The evolution of the fleet type submarine during the years of peace preceding World War II was the result of hypothesis and experience obtained through simulated exercises rather than actual war service conditions. The operating characteristics of the fleet type submarine proved adequate to carry the war to the enemy throughout the entire Pacific area, although great distances were involved.

2-6. U.S. submarine operations in the Atlantic during World War II were on a minor scale. Throughout the entire war only four enemy vessels were sunk by our submarines in the Atlantic, two of the four being German submarines, and but five other enemy vessels were damaged.2 Only one U.S. submarine was damaged in the Atlantic through enemy action.3 In the Pacific, however, where the major portion of our submarine effort was exerted, the U.S. submarine service established an impressive record almost from the first day of our entry into the war. Unrestricted submarine warfare against Japan was ordered by the Chief of Naval Operations on 7 December 1941. With the exception of a few special missions and support operations during the Battle of Midway and the initial phases of the Solomons Campaign, submarines were employed during the first two years of the war as free agents in a campaign of attrition against enemy combatant vessels and merchant shipping. With the inauguration of the Gilbert Islands campaign in November 1943, a gradually increasing percentage of the submarine effort was diverted to the support of fleet operations although normal offensive patrolling continued to the end of the war. The statistics of the Joint Army-Navy Assessment Committee credit U.S. submarines with the sinking of 54.6 percent of all Japanese naval and merchant vessel tonnage sunk during World War II by U.S. forces of all categories. The total of sinkings

___________

1 So far as can be determined, the first vessel credited as destroyed by submarine action in the history of the U.S. Navy was the Japanese cargo ship ATSUTASAN MARU (8,662 gross tons), sunk in World War II by SWORDFISH (SS193) on 16 December 1941, lat. 18° -06N., long. 109° -44'E. (credited by the Joint Army-Navy Assessment Committee, NavExos Publication P-468).

2 Submarine Operational History, World War II, prepared by Commander Submarine Force, U.S. Pacific Fleet (Preliminary Issue).

3 BLACKFISH (SS221), damaged by German depth charge attack in the Bay of Biscay on 19 February 1943. See brief of damage in Appendix I.

credited to U.S. submarines includes 201 Japanese naval vessels with a combined tonnage (standard displacement) of 540,192 tons, 29.6 percent of all Japanese naval tonnage sunk by U.S. forces, and 1113 merchant vessels above 500 gross tons with a combined tonnage (gross) of 4,779,902 tons, 60.4 percent of all Japanese merchant tonnage sunk by U.S. forces.1,2 The following numbers and types of combatant Japanese naval vessels were sunk by U.S. submarines: 1 battleship, 4 large aircraft carriers, 4 escort aircraft carriers, 3 heavy cruisers, 8 light cruisers, 38 destroyers, 23 submarines and 100 escort, patrol or mine vessels. In addition to the 1314 naval and merchant vessels credited as sunk, approximately 1000 Japanese vessels in all categories, with an estimated combined tonnage of over 5,000,000 tons, were damaged by U.S. submarines.3 It has been estimated that approximately 275,000 Japanese were killed as a direct result of Allied submarine operations.4

2-7. On 7 December 1941 there were 46 fleet type, 2 - 800 ton-type, 37 S-type, 18 R-type and 7 O-type submarines in commission in the U.S. Navy. Of these, 39 fleet type and 12 S-type were in the Pacific. On 15 August 1945, the day the war ended, there were 200 fleet type, 15 S-type, 10 R-type and 5 O-type submarines in commission. Of these, 169 fleet type and 13 S-type submarines were in the Pacific. A total of 202 fleet type submarines were completed and commissioned during the war.5

2-8. In all theatres during World War II, 269 U.S. submarines conducted a grand total of 1682 war patrols against the enemy. 251 submarines made patrols in the Pacific, of which 229 were fleet type boats and 22 were S-type boats. Of the total of 1682 war patrols, 948

____________

1 Japanese Naval and Merchant Losses During World War II by All Causes, NavExos Publication P-468 of 3 February 1947, prepared by the Joint Army-Navy Assessment Committee. The figures of this committee are very conservative as compared with the official statistics of the various force commands.

2 ONI Statistical Section (Op-32F-44) data credits German submarines with the destruction of 2,321 naval and merchant vessels of the United Nations, for a grand total of 12,866,711 tons, during the period from September 1939 to the German surrender in May 1945.

3 Submarine Operational History, World War II, prepared by Commander Submarine Force, U.S. Pacific Fleet (Preliminary Issue).

4 Figure given by Japanese to the Administrator, U.S. Naval Shipping Control Authority for Japanese Merchant Marine. (Submarine Force Pacific Fleet Bulletin, Volume III, Number I of February 1946.)

5 During the period from September 1939 to their surrender in May 1945, the Germans built a total of 1100 submarines, divided into the following categories: 912 attack type submarines which became operational; 119 Type XXI attack submarines which were delivered by the final assembly yards but none of which became operational due to hydraulic system defects; 10 experimental submarines; and 59 submarines designed for special service such as minelayers, cargo carriers and submarine tenders. - NavTechMisEu Technical Report No. 312-45 of August 1945 entitled "German Submarine Design, 1935-1945."

were conducted under the command of ComSubPac, 622 under the command of ComSubSoWesPac and 112 under the command of ComSubLant.

2-9. A survey of war patrol reports and other information available to the Bureau indicates that there were 110 separate instances, excluding losses, in which our fleet type submarines sustained damage from attack by either enemy or friendly forces where the damage received can be considered as more than negligible, or where the circumstances of the attack or the nature of the damage has been considered of sufficient interest to warrant mention. Brief accounts of each of the selected actions have been included in Appendix I of this report. The 110 cases of damage can be classified by cause as follows:

| Depth charge | 58 |

| Bomb | 25 |

| Depth charge and bomb | 8 |

| Aircraft strafing or small caliber gunfire | 6 |

| Medium caliber gunfire | 4 |

| Collision | 4 |

| Mass detonation of target ship | 2 |

| Mine | 1 |

| Kamikaze aircraft | 1 |

| Own torpedo | 1 |

| 110 |

Of these 110 cases, about 15 can be classified as resulting in severe damage, about 50 as resulting in moderate damage, and the remaining 45 as resulting in only minor damage.

2-10. In 49 of the above 110 cases, the submarines were forced to terminate their patrols as a result of the war damage received. In many of these instances, the damage which caused the termination of a patrol was restricted to but one vital system or equipment and the sum of all other damage was only minor or even non-existent. For example, in TROUT's (SS202) action of 3 October 1942, only the periscopes were damaged but this casualty alone forced the ship to return to base for repairs. It is difficult in many of the cases where war damage forced termination of patrols to assign any one or two specific items of damage as being responsible. When damage was widespread, even though each item may in itself have been fairly minor or capable of being repaired by ship's force, the cumulative effect of the total was often sufficient to force the boat to return to base for repairs. A review of the 49 war patrols which were terminated due to war damage indicates that the following classification by cause can be made:

| General severe damage | 15 |

| Widespread minor damage | 4 |

| Periscope damage (by explosion) | 5 |

| Periscope damage (by collision) | 4 |

| Medium caliber gunfire damage | 4 |

| Leakage rendering depth control difficult | 3 |

| Reduction gear damage | 3 |

| Conning tower door damage | 1 |

| Bow damage (collision) | 1 |

| Strafing attack | 1 |

| Derangement of stern planes | 1 |

| Conning tower plating failure | 1 |

| Control cubicle derangement | 1 |

| Oil leakage from external tanks | 1 |

| Contamination of hydraulic system with salt water | 1 |

| Damage to torpedo tube fittings | 1 |

| Damage to torpedoes | 1 |

| Small caliber gunfire (40mm) | 1 |

| Total | 49 |

2-11. Fifty-two U.S. submarines were lost from all causes during the period 7 December 1941 to 15 August 1945.1 A summary of these losses, with pertinent information where available, is presented in Appendix II. Of the total of fifty-two losses, at least nine were due to causes other than direct enemy action: four stranded on reefs during war patrols and were abandoned; two were lost due to operational or materiel casualties while on training exercises; one was lost by collision with a U.S. surface vessel while proceeding to her patrol area; and two were sunk by the malfunctioning of their own torpedoes. In addition, one was destroyed by Japanese bomb attack while under overhaul at Navy Yard, Cavite, P.I. The remaining forty-two submarines were lost at sea either through enemy action or for reasons unknown. The circumstances regarding the loss of six of these forty-two submarines are known from survivors' reports: two were scuttled after damage received by depth charge attack; one was scuttled after damage received by bomb attack; two were destroyed by mine explosions while running surfaced; and one was sunk by direct hits from medium caliber gunfire. The fate of the other thirty-six submarines is not definitely known. Assessment of the various sources of information enumerated in Appendix II of this report results in the following estimate: twenty-one submarines, probably or possibly sunk by depth charge and/or bomb attack; five probably or possibly sunk by mines; two possibly sunk by gunfire; one probably sunk by gunfire after being forced to the surface by depth charge attack; one probably destroyed, while surfaced, by Japanese torpedo attack; and six submarines whose loss remains in the unknown category.

__________

1 Enemy submarines destroyed from all causes in World War II totaled 996, including 781 German, 85 Italian and 130 Japanese. (Statistics compiled by the British Admiralty and United States Navy Department Assessment Committees. Intelligence received from enemy sources after the termination of the war was considered in this evaluation.)

2-12. Eleven cases of submarine loss or damage have been taken up in detail in this report and are grouped as follows: four cases of depth charge damage, including one loss; two cases of bomb damage, including one loss; one loss by torpedo damage; one case of damage by mine; one case of damage by medium caliber gunfire; one case of damage by collision and small caliber gunfire; and one case of damage by grounding while submerged. The cases have been selected to include not only the most serious instances of damage sustained by our submarines during World War II but also to illustrate the effect of underwater detonations at various points along the length of a submarine. The text of each case includes a narrative describing the action, the damage and its effect on the submarine, the damage control measures taken, the habitability aboard the submarine after damage, a discussion of the ordnance material which inflicted the damage, and such conclusions as may be drawn regarding materiel behavior.

2-13. Most of the information on the individual ship actions has been obtained from the respective Commanding Officers' patrol reports, the reports of war damage submitted by the Commanding Officers following the form of the Bureau's letter C-FS/L11-1(374); C-EN28/A2-11 of 17 April 1942 which was distributed to all vessels in the U.S. Navy, the supplementary war damage reports submitted by the various repair activities or Naval Shipyards, and survivors' reports in those cases where loss of the vessel occurred.

2-14. It is realized that the preparation of detailed reports during wartime often may be onerous to the individual concerned, especially when the press of other duties is extreme. However, it is through such reports that the forces afloat and field activities can keep the Department fully aware of significant developments and the need for design changes or materiel improvements. It is emphasized that reports of damage and loss have served as a basis for improvements in both design and equipment.

3-1. Much interesting and hitherto unknown information on the Japanese anti-submarine warfare effort was gathered at the end of World War II by representatives of the U.S. Naval Technical Mission to Japan.1 The most striking feature commented upon was the enormous gulf between the Japanese conceptions of such warfare and their actual accomplishments. The Japanese high command had given consideration to almost every phase of advanced anti-submarine warfare. Much thought and research effort was directed towards the development of echo-ranging equipment, influence and acoustic proximity-fuzed depth charges, deep-setting depth charge pistols, chemical recorders, ultra high frequency voice radio, surface search radar for escort ships and aircraft, magnetic detection equipment for aircraft, ahead-thrown rockets and standardized and improved doctrine for surface and joint air-surface offensive action. Satisfactory solutions to many of these problems were obtained and limited production of equipment and operational training were undertaken.

3-2. Nevertheless, at the end of the war Japanese anti-submarine warfare was still being waged without appreciable benefit from the results of their research effort. Lack of production facilities, inability to maintain adequate supply lines, and the necessarily large allocation of production to aircraft for the final defense of the Empire home islands greatly affected the anti-submarine forces, but there also existed a failure on the part of operating personnel to use what they did have to best advantage.

3-3. Although the importance of use of radar to detect submarines was recognized, many escorts were never fitted with surface search radar due to lack of equipment.2 Even those escorts which had been equipped with search radar and improved echo-ranging devices were in most cases unable to obtain satisfactory results, due to defective equipment and poor training of maintenance and operating personnel. However, both combatant ships and escorts were generally provided quite early in the war with effective directional equipment to detect radar being used by U.S. submarines. 2

3-4. The value of aircraft radar in anti-submarine work, both for search and blind attack, was also well recognized. Here again, their equipment was decidedly inferior and pilots generally were either poorly trained or lacked confidence in its use and are reported to have

___________

1 NavTechJap Target Report, Index No. S-24, of 8 February 1946 (Japanese Anti-Submarine Warfare).

2 Japanese anti-submarine escorts did not begin receiving radar surface search equipment in quantity until about September 1944. Previous to that date, very few escorts were equipped with search radar since most of the available production was allocated to combatant ships. Radar-detection receivers were installed on most escorts by April 1944. - U.S. Strategic Bombing Survey, Naval Analysis Division, Interrogation No. 61.

had but little success in radar bombing attacks. Airborne radar was first used in medium bombers as early as September 1943 but there was no large-scale employment of radar-equipped planes for antisubmarine work until the fall of 1944. Their equipment was reported to have been capable of detecting a surfaced submarine at a range of twelve miles. However, Japanese doctrine called for use of airborne radar only during night or low visibility conditions because visual search was still considered more reliable. Towards the end of the war, Japanese radar-equipped planes were making numerous contacts with our submarines but few attacks resulted. In 1945 a few antisubmarine aircraft were also provided with radar detection receivers but the Japanese professed to have never reached the stage of homing on U.S. submarine radar. However, war patrol reports indicate that at least some enemy pilots achieved moderate success in using such equipment for initially detecting the presence of our submarines. Precise locating was probably then accomplished with aircraft search radar rather than radar detection equipment.

3-5. By late in 1943, the Japanese had successfully developed a magnetic airborne detector (MAD) and, commencing in March 1944 this equipment was put into operational use by both the Army and Navy for anti-submarine patrol.1 Range of detection was reported to have been about 120 meters under average conditions and about 250 meters was claimed under ideal conditions. Since expert pilots flew magnetic search planes only thirty to forty feet above the surface, the apparatus was therefore presumably capable of detecting a submarine at well over 300 feet submergence. Aircraft equipped with MAD were employed principally to search ahead of convoys or to exploit a submarine contact made by other means. Although it was planned to use such aircraft to sweep all heavily travelled convoy routes, lack of both aircraft and MAD equipment prevented this. The instrument was considered sufficiently reliable to warrant calling in surface craft whenever an initial contact had been established. The types of planes normally used for anti-submarine work, and equipped with MAD and/or radar when possible, were NELL, JAKE, KATE, JILL, DAVE, BETTY, ZEKE and EMILY.2 By the end of the war only about one-third of the shore based anti-submarine planes had MAD, about one-third had radar, and only a very few were equipped with both. Anti-submarine planes were very seldom fitted with guns which accounts for the low incidence of strafing attacks against U.S. submarines.

3-6. Only one small land-based "hunter-killer" air-surface group existed and even this was not organized until early 1945.3 The group covered the East China Sea between Formosa and Shanghai and was comprised of five surface ships (DE types) known as the 102nd Surface Squadron and about 20 Navy fighters (ZEKES) of the 934th Squadron,

___________

1 NavTechJap Target Report, Index No. E-14 (Japanese Magnetic Airborne Detector).

2 U.S. Strategic Bombing Survey, Naval Analysis Division, Interrogations Nos. 200 and 371.

3 NavTechJap Target Report, Index No. S-24 (Japanese Anti-Submarine Warfare).

Shanghai Air Force. These planes were equipped with both radar and magnetic airborne detectors. For routine patrol, the planes usually carried two 60 Kg. depth bombs and when sent out to attack a previously detected submarine carried one 250 Kg. depth bomb, although the 250 Kg. size depth bombs were also sometimes carried on patrol. Both the planes and surface escorts were provided with voice radio but could communicate only for short distances and frequently were unable to communicate at all due to technical difficulties.

3-7. The Japanese repeatedly demonstrated facility in detecting and locating submerged submarines by using sonar. Their underwater listening gear was fairly good and could frequently pick up our submarines at ranges of 2000 meters or more when the listening ship was stopped or proceeding at very slow speed. A damaged submarine with a high machinery noise level, such as a reduction gear click, could of coarse be heard at a far greater distance than an undamaged submarine running silent or creeping. Their echo-ranging equipment was of mediocre design, roughly corresponding to the early U.S. QC sonar of about 1937. The emphasis which the Japanese placed on sonar devices is clearly shown by the unnecessarily large amount of space allocated to such equipment in the already cramped quarters of their ships. At sea it was customary to man the hydrophone set continuously and to operate the echo-ranging gear at least fifteen minutes in every hour. Small escorts were generally provided only with listening gear, in some instances just a crude hydrophone lowered over the side. Japanese scientists were cognizant of density layers and temperature gradients in sea water and their effect on sound transmissions in echo-ranging detection work. However, anti-submarine vessels were not equipped with bathythermographs and no tactical use was apparently made of the small amount of information of operational value issued by the Japanese Hydrographic Office.

3-8. The depth charge was the primary Japanese surface ship antisubmarine weapon. Depth charges were placed aboard practically every type of ship capable of carrying them and even the smallest of patrol craft could generally be expected to have a few. Very slow craft used parachutes to reduce the sinking rate of their charges so as to reach a safe distance from the detonations. The Japanese used depth charge throwers extensively and even merchant ships were occasionally equipped with these. Fleet destroyers generally carried about 30 depth charges. Frigates (KAIBOKAN) could carry as many as 300 and were usually fitted with twelve single depth charge throwers, six to a side, and one stern rack. The Japanese PC-13 Class, by far the most numerous of their PC types, carried about 36 charges with two side throwers and one stern rack. Gun armament for the PC-13 Class consisted of one 8 cm. dual purpose and one twin 13mm machine gun.

3-9. There were only two types of depth charges in general use by the Japanese for surface ship launchings and both were almost exact copies of early British models of obsolete design. These were the Type 95, the Type 2, and the various modifications of each.1

____________

1 Handbook of Japanese Explosive Ordnance, OpNav 30-3M of 15 August 1945 and Bureau of Ordnance Pamphlet 1507 of 20 April 1945.

The Type 95 was the regular issue depth charge until the development of the Type 2. Although the Type 2 charge was adopted in 1942, Type 95 charges are known to have still been manufactured up to 1943. Both charges were probably in use during 1943 until available supplies of the Type 95 were finally exhausted. The Type 95 depth charge was cylindrical in shape, 17.75 inches in diameter and 30.5 inches long. The Type 95, Mod. 0 was filled with 220 pounds of Type 881 explosive and a Shimose2 booster; the Mod. 1 with 325 pounds of Type 973 or Type 984 explosive; and the Mod. 2 with 242 pounds of Type 15 explosive. The Type 2 depth charge was also cylindrical in shape, 17.56 inches in diameter and 30.5 inches long. The Type 2, Mod. 1, was filled with 357 pounds of Type 97 or Type 98 explosive and the Mod. 2 with 242 pounds of Type 1 explosive.

3-10. The pistols for both the Type 95 and Type 2 depth charges were also almost exact copies of early British models and both operated on the same depth setting and firing principle, although they were not interchangeable between the two types of charges.6 The firing mechanism of both pistols was actuated by the hydrostatic pressure of sea water flowing through a small orifice and slowly filling up an inner cylinder. Depth setting was accomplished by varying the size of the water inlet, thus determining the amount of time required to fill the inner cylinder. The smaller the inlet, the deeper the setting. The Type 95 depth charge pistol used early in the war could be set for operation only at depths of 98 feet, 98 feet with parachute, 197 feet, and "Safe". Later modification of this pistol provided for an additional setting of 292 feet. The maximum range of depth settings for the Type 2 depth charge pistol was much greater, a choice being available of 98 feet, 197 feet, 292 feet, 390 feet, 480 feet, and "Safe". It was apparently not possible with either type pistol to choose depth settings other than those enumerated above, even though detonation at some intermediate depth might be considered desirable.

3-11 No data are available as to how much variation could normally be expected between the prescribed depth settings on the pistols and the depths at which charge detonation would actually occur. The amount of error would naturally be affected by variations in sinking rates due to the following factors: (a) the method of launching, i.e., whether the charges were projected from throwers or dropped from stern racks; and (b) by the condition of the sea, i.e., whether still or disturbed. The accuracy

____________

1 Type 88 explosive - 75% ammonium perchlorate, 16% ferro-silicon. More powerful than TNT. Power compares favorably with explosives containing aluminum.

2 Shimose - Almost pure picric acid. Slightly more powerful than TNT.

3 Type 97 explosive - 60% trinitrotoluene, 40% hexanitrodiphenylamine. Slightly less powerful than TNT.

4 Type 98 explosive - 60% trinitroanisole, 40% hexanitrodiphenylamine. Power is approximately that of TNT.

5 Type 1 explosive - 81% ammonium picrate, 16% aluminum. Power compares with that of Torpex or about one-third to one-half greater than TNT.

6 Handbook of Japanese Explosive Ordnance, OpNav 30-3M of 15 August 1945 and Bureau of Ordnance Pamphlet 1507 of 20 April 1945.

with which the orifices in the pistols were initially machined would also affect the detonation depth. Tests conducted by the British on their early pistols indicated that discrepancies of as much as 60 feet should be expected for charges set for detonation at 250 foot depth. It should be noted that even though a Japanese depth charge were to come to rest in water more shallow than that for which its pistol had been set, it would still fire when sufficient water had seeped through the entry orifice to provide the minimum pressure required. This is believed to account for many of the delayed depth charge detonations which have been reported by U.S. submarines.

3-12. The maximum depth setting possible with the Type 95 depth charge is believed to have been 292 feet and the maximum setting normally used for the Type 2 charge was 390 feet. A proportionate number of charges with these maximum settings were usually included in each attack pattern. Our submarines reported only a few cases where depth charges were set for depths in excess of 400 feet.1 As the Japanese were unable to estimate the depth of a submerged target, no specific technique was developed for attacking submarines that took refuge in deep submergence. The only deep setting depth charge pistol developed was the Type 3, Models 1 and 2, designed for operation at 131, 262, 393, 524 and 656 feet. 2 The design of this pistol was similar to that used in both the Type 95 and Type 2 depth charges but the extra time required to reach the greater depth was provided by a delay train initiated by the firing pin. However, issue to ships had not become general by the end of the war and no specific doctrine for its use had been developed.

3-13. Although the need for proximity-fuzed depth charges seems to have been appreciated, none were developed in time for operational use during the war. The Japanese Type 4 depth charge, designed for magnetic actuation, had been developed but trials on it were still in progress when the war ended.2 An acoustic type depth charge was also scheduled for development but work on this did not proceed beyond the preliminary design stage and no prototypes were made.

3-14. At least two types of anti-submarine explosive weapons designed for underwater tow by small surface vessels are known to have been developed and used by the Japanese, particularly early in the war. The first of these was called the "Yokosuka depth charge" and was set to explode upon contact with a submerged object. The charge was cylindrical in shape, about 1 foot in diameter by 5 feet in length, and contained 55 pounds of Type 88 explosive filler.3 The

____________

1 While being depth charged on 4 July 1944, during her fifth patrol, SEAHORSE (SS304) reported that her DGDI indicated a few charges were definitely detonating below the ship even though her depth at that time was 470 feet. THREAD FIN (SS410) reported that while being depth charged on 28 March 1945, during her second patrol, over half of the detonations occurred at depths greater than 450 feet as indicated by DCDI.

2 NavTechJap Target Report, Index No. 0-08 of 16 December 1945 (Japanese Depth Charges).

3 Handbook of Japanese Explosive Ordnance, OpNav 30-3M of 15 August 1945.

second weapon was designated by the Japanese as the Mark 2 Explosive Hook and, although developed primarily for minesweeping, was occasionally used for anti-submarine work. This device was a cast iron cylinder, 8 inches in diameter and ten inches long with four grapnel-like arms projecting from the main body, each 7-1/2 inches long. The body contained a charge varying from 8 to 19 pounds of Type 88 explosive.1 Firing was accomplished after the hook secured on a submerged target; the Mod. 0 either electrically by an observer on the towing ship or automatically when an additional tension of 550 pounds was put on the towing line, and the Mod. 1 by electrical control from the towing ship. Although several reports were received from U.S. submarines of small Japanese vessels apparently using these tow weapons, no large-scale employment was made and there is no information to indicate that damage was ever inflicted.2

3-15. Three sizes of aerial depth bombs were developed by the Japanese Navy specifically for anti-submarine work and were used for this purpose by both Army and Navy aircraft.3 These were designated by the Navy as Mark 2 bombs and by the Army as Type 4 bombs. They were fitted with anti-ricochet nose rings and had considerably higher explosive-loading factors than ordinary general purpose bombs. The smallest of the three was a 60 Kg. bomb, designated by the Navy as the Type 99, No. 6, Mk. 2, Mods. 0 and 1, and was loaded with 85 pounds of Type 98 explosive. These small bombs were carried primarily by planes on routine anti-submarine patrol and were considered to have a lethal range of 12 to 15 feet. The second was a 180 Kg. bomb designated as the Experimental 19, No. 25, Mk. 2, loaded with 308 pounds of Type 98 explosive. This bomb was developed primarily for use in conjunction with planes equipped with magnetic airborne detectors and was considered to have a lethal range of about 25 feet. The third and largest was a 250

____________

1 Handbook of Japanese Explosive Ordnance, OpNav 30-3M of 15 August 1945.

2 On 8 September 1943, during her first patrol, BILLFISH (SS286) sighted a Japanese convoy escorted by a small converted merchantman and a sampan, the latter dragging two cables over the stern. During the subsequent depth charge attack, a distinct scraping sound was heard down the port side of the hull while at a depth of about 300 feet. This probably was an explosive sweep. In at least two instances, U.S. submarines were caught by grapnels but managed to escape without damage. (a) While submerged off the entrance to Kwajalein on 9 July 1942, during her fourth war patrol, THRESHER (SS200) was hooked in her after superstructure by an unknown type of Japanese grapnel. It was reported that the pull of the grapnel line made the boat noticeably light aft. The grapnel was finally cleared, after ten minutes, by running at high speed with full right rudder and by increasing depth to 350 feet, (b) On her sixth war patrol, CREVALLE (SS291) was hooked in her periscope shears by a crude four-pronged grapnel. The grapnel line broke and the grapnel itself fell to the deck and was recovered upon surfacing.

3 Handbook of Japanese Explosive Ordnance, OpNav 30-3M of 15 August 1945 and NavTechJap Target Report, Index No. 0-23 of December 1945 (Japanese Bombs).

Kg. bomb designated as the Type 1, No. 25, Mk. 2, Model 1, Mods. 0 and 1, and was filled with 317 pounds of Type 98 explosive. This 250 Kg. bomb was considered to have a lethal range of about 33 feet and was generally only loaded on aircraft when a definite contact had been established by other planes or surface craft.

3-16. All three of the above Mark 2 depth bombs carried time rather than hydrostatic fuzes, and depth settings could only be varied by changing the fuze gaines prior to loading the bombs on aircraft. Four different fuze games with different time delays were used for anti-submarine work, each of which could be used with all standard Navy bomb fuzes, which in turn would fit any of the three Mark 2 bombs. The first game, the only variable setting design adopted by the Japanese, was designated as the Type 15 and could be set for detonation at any desired delay between 0 and 1.5 seconds after striking the surface of the water, equivalent to between 0 and about 50 foot depth.1 The desired setting had to be selected prior to insertion of the gaine in the bomb fuze. Although the Type 15 gaine was not developed specifically for anti-submarine bombs, it is known to have been used extensively for the purpose of attacking surfaced or submerging submarines. Each of the other three fuze gaines had a pre-fixed time delay and all three were designated as the Type 1, Mark 2 design. The Model 5 was set for detonation after 3.5 seconds delay, about 80 foot depth; the Model 1A after 6 seconds delay, about 150 foot depth; and the Model 1B after 17 seconds delay, about 300 foot depth.1 The Japanese referred to bombs fitted with the Models 5 and 1A gaines as "25 meter" and "45 meter" bombs and these were the types generally carried, although the gaines were naturally varied to suit the expected conditions.

3-17. When anti-submarine Mark 2 Navy bombs were not available, the Japanese substituted common types of 60 Kg. and 250 Kg. Navy GP bombs or Army 50 Kg., 100 Kg. and 250 Kg., Type 3 bombs. Army aircraft frequently carried a mixed load of their own Type 3 bombs along with Navy Mark 2 bombs, the Type 3 bombs being fuzed instantaneously, with short delays, or with a nose plug and a special 3.5 second delay tail fuze.

3-18. The Japanese directed considerable effort toward the development of gun projectiles for anti-submarine work which would continue an undisturbed trajectory after striking the water. After extensive tests in 1943, a flat-nosed projectile was adopted in which the area of the flat front was equal to half the area of the base. Projectiles of this non-ricochet type were produced for guns up to and including 8-inch.

3-19. Many U.S. submarines reported hearing small "sono-bomb" or "light" explosions while submerged and in contact with Japanese surface units. SALMON (SS182) likened the noise of such successive explosions to a "string of fire-crackers". These "sono-bombs" are believed to have been the Japanese Mark 3 and Mark 4 "Emit Sound Missiles" (HATSUONTO). This device consisted of a can 8 inches long and 5 inches in diameter, filled with Type 88 explosive. When dropped

____________

1 The time delays given here are based on U.S. tests and do not agree with the figures contained in Japanese documents. The depths corresponding to these time delays have been computed for bombs dropped from an aircraft traveling at 100 knots at an elevation of 100 feet.

into water, a small quantity of sodium under the top cap explodes, blowing the cap off and operating a pull igniter. Then after a short delay, the explosive charge detonates. These missiles were employed by the Japanese for the training of their own submarine crews, to simulate depth charges in an attempt to frighten Allied submarines away,1 and later were employed very successfully in sweeping U.S. - laid acoustic mine fields. Many of these "light" explosions heard just prior to depth charge detonations may also have been caused by the sound of depth charge throwers or possibly even gunfire in some cases.

3-20. Although mines were used by the Japanese as an anti-submarine measure and certainly constituted an appreciable hazard, such mining never became really extensive during any phase of the war, probably due to lack of mine-laying vessels.2 Both contact and controlled mine fields were laid in Empire coastal waters and harbors, the accesses to the Sea of Japan, the southern approaches to the Empire, Formosa and the Philippines. The most commonly used contact mine was the Type 93, containing 220 pounds of Type 88 or Type 1 explosive.3 This was a moored mine and was designed to arm only with tension on the mooring spindle, a drifting Type 93 mine therefore being disarmed except for those cases where the arming mechanism was locked closed by corrosion. The most commonly used controlled mine was the Type 92, containing 1100 pounds of Type 88 explosive.3 This was also a moored mine and could be either acoustically or magnetically monitored from shore or small vessels. The Japanese copied the design of two German magnetic and acoustic proximity-fuzed ground mines which were brought to Japan by a German vessel in September 1942 and produced their own adaptations by March 1944, both designed for planting by submarine. There is evidence that such mines were laid off Truk4 and in one area off the east coast of Australia2, but aside from these two locations there is no indication that proximity-fuzed mines were used anywhere else. The development late in the war of the QLA sonar mine detector made possible the penetration of enemy minefields by our submarines and permitted spectacular operations in areas long considered invulnerable by the Japanese, such as the Sea of Japan.

3-21. The greatest disparity between the weapons employed in the Japanese anti-submarine program and ours was their failure to develop an ahead-thrown contact weapon similar to our Mark 10 Projector ("Hedgehog"). Some development work was done on ahead-thrown rockets fired in salvos of five from "rocket guns" but results were not satisfactory and the project was abandoned. This was the only type of ahead-thrown anti-submarine weapon under consideration by the Japanese. The U.S. Mark 10 "Hedgehog." projectile is fuzed to detonate on contact and the charge size (33 pounds Torpex) is

____________

1 JICPOA captured Document No. 78745 records their use in this manner by a Japanese merchant ship and CinCPac-CinCPOA captured Item No. B-10202B also records such use by Japanese destroyers during the central action of the Battle for Leyte Gulf, 24-26 October 1944.

2 NavTechJap Target Report, Index No. 0-05 (Japanese Naval Mining Organization and Operational Techniques).

3 Handbook of Japanese Explosive Ordnance, OpNav 30-3M of 15 August 1945

4 Field Survey of Japanese Defenses at Truk, Part I, CinCPac-CinCPOA Bulletin 3-46 of 15 March 1946.

such that rupture of the pressure hull is to be expected even when detonation occurs at the superstructure. The tactical problem is simplified, for usually contact is not lost prior to launching of a "Hedgehog" barrage and no interference with sound apparatus will occur until a hit is obtained. Probability studies based upon the various factors entering into an attack on a submerged submarine and statistical analysis of action reports indicate that a submarine's chance of surviving a depth charge barrage are at least four times as great as the probability of surviving a "Hedgehog" attack.1

3-22. The Japanese failed to achieve optimum use of their principal anti-submarine weapon, the depth charge, simply by repeatedly setting their pistols too shallow. There are many instances reported by our submarines, especially during the first two years of the war, in which depth charge patterns detonated directly overhead without causing appreciable damage but where an increase in depth setting would probably have resulted in fatal or serious damage. Above all, the Japanese generally lacked persistence in both their search efforts and exploitation of a positive contact, once made. They were prone to accept the slightest evidence that a submarine had been destroyed and then depart. Many a U.S. submarine owes its escape to the Japanese predisposition to take the most optimistic view.

____________

1 From Operations Evaluation Group Report No. 51. This applies only to depth charges having pistols with preset depth settings, such as those used by the Japanese, and not to proximity-fuzed depth charges. An attack made with the latter is theoretically only slightly less effective than a "Hedgehog" attack.

U.S.S. PERCH (SS176)

Loss in Action

Java Sea

3 March 1942

| Class | SS173 |

| Builder | Electric Boat Co., Groton, Conn. |

| Commissioned | 19 November 1936 |

| Length (Overall) | 300 ft. 6-3/4 in. |

| Beam (Extreme) | 25 ft. 1-1/2 in. |

| Submergence Depth (Designed Maximum)(Axis) | 250 ft. |

| Displacements | |

| Standard | 1330 tons |

| Emergency Diving Trim | 1725 tons |

| Submerged | 2005 tons |

| Draft (Mean, Emergency Diving Trim) | 16 ft. 11 in. |

| Type of Propulsion | Diesel Electric Reduction Drive |

| Main Engines (4) | Winton 16-201A |

| Main Motors (8) and Generators (4) | General Electric Co. |

References:

(a) Enclosure (B) to ComSubsPacAdmin secret ltr. FF12-10(A)/A4-(1)/A16-2, Serial 00349 of 21 September 1945 (Commanding Officer PERCH Statement Concerning Loss of Vessel).

(b) ComSubsPacAdmin ltr. FF12-10(A)/A16-2, Serial 3599 of 12 October 1945 (Statements of Two PERCH Crew Members Concerning Loss of Vessel).

(c) ComSubsPac Report Entitled "Enemy Anti-Submarine Measures", no date or file number given (Account of Loss of PERCH).

(d) Account of Loss of PERCH as Related to Cdr. I.F. Duff, (MC), USNR, by Lt.Cdr. J.J. Vandergrift, Jr., USN, on 5 April 1946.

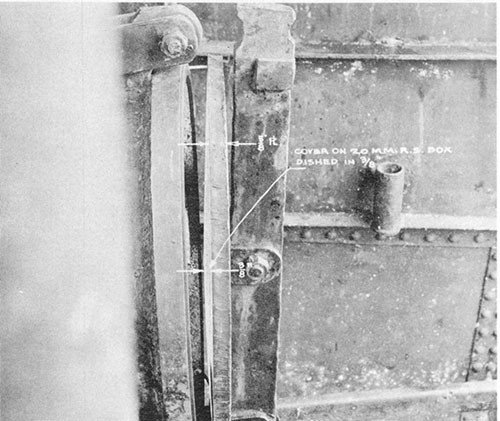

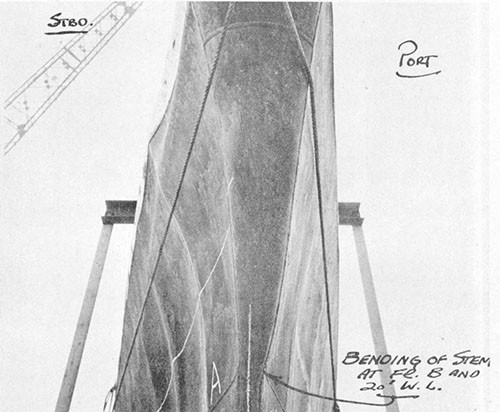

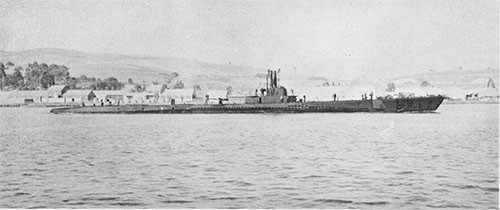

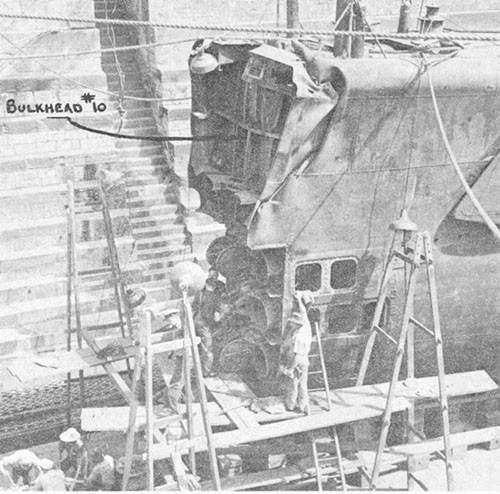

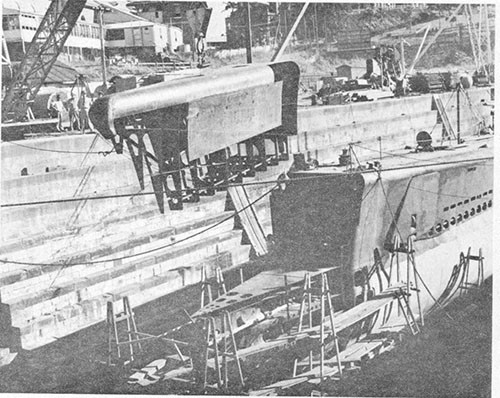

Photograph No. 4-1

4-1. On 2 March 1942, while operating in the Java Sea on her second war patrol, PERCH sustained severe depth charge damage which prevented further submerged operations and reduced her maximum surface speed to about 5 knots. Shortly after dawn on 3 March, PERCH was deliberately scuttled by her own crew to prevent imminent capture by Japanese surface forces. This report is based on the information contained in references (a) through (d). These references are accounts furnished from memory by various survivors of PERCH upon their release from Japanese prisoner of war camps at the end of the war, almost four years after the action took place. It naturally follows that the source data are not as complete and cannot be considered to have the same degree of accuracy as formal war damage and action reports written shortly after an action.

4-2. After normal refit, PERCH departed Port Darwin, Australia, for her second war patrol on 3 February 1942. At this time the Japanese campaign to secure the Netherlands East Indies was in full swing. PERCH was directed to patrol and perform reconnaissance in various positions in the Java and Flores Seas as part of the force then attempting to defend Java.

4-3. On the night of 25 February 1942, while patrolling the southern approaches to Kendaris, Celebes, PERCH sighted a Japanese supply ship and commenced approach for a surface attack. However, the enemy ship opened fire and scored one three-inch shell hit on PERCH which struck the light fairwater plating just forward of the conning tower proper and detonated inside the "doghouse". The pressure-proof radio antenna trunk and 200-pound air line to the whistle were ruptured, several electrical cables were cut by shrapnel, and the pressure-proof magnetic compass trunk system was flooded. Action was terminated without further damage. Temporary repairs were made by ship's force to the radio antenna trunk which permitted subsequent radio transmission.

4-4. The following night, PERCH was ordered westward into the Java Sea after a large Japanese convoy of troopships had been sighted near Bawean Island with apparent intentions of landing forces on Java. On 27 February, the Battle of the Java Sea occurred, ending all organized Allied surface resistance in the East Indies area. The Japanese landed on the northern coast of Java on 28 February. That night PERCH received notification of the exact landing point of the convoy and was ordered to disregard previously assigned areas and to attack.

4-5. On the next night, 1 March, PERCH was still proceeding west toward the designated landing area, and had reached a position about twelve miles northwest of Soerabaja, when two Japanese destroyers were sighted. PERCH was at this time running on the surface so she made a quick dive to avoid detection. There was a full moon and visibility conditions were excellent. The destroyers passed well clear astern and out of torpedo range but turned back after proceeding about four or five miles. One of the destroyers then came in close

on a course favorable for stern torpedo shots and PERCH made ready for attack, taking frequent periscope observations. However, on the last periscope check before firing, it was noted that the target destroyer, which was distant about 800 to 1000 yards at this time, had obviously detected PERCH and was charging in at high speed for an attack.

4-6. The Commanding Officer, believing he was in 200 feet of water, immediately ordered depth increased to 180 feet. When PERCH had reached a depth of about 90 to 100 feet, however, the destroyer passed directly overhead and dropped several depth charges. This first pattern was not close and caused no appreciable damage. Shortly afterwards, PERCH struck bottom at about 147 feet depth with her propellers still turning over and while in this position received a second pattern of four depth charges, this time very close. This group of charges was apparently dropped by the second destroyer. Considerable damage was sustained aft and all main motor field relays tripped, causing temporary loss of propulsion. While still on the bottom, a third and final depth charge pattern was received very close aboard amidships. The enemy destroyers then ceased further attacks, apparently convinced that PERCH had been destroyed, although they remained in the immediate area.1

4-7. Extensive damage was caused by the second and third depth charge patterns. As mentioned previously, all main motor field relays tripped, causing temporary loss of propulsion until they were reset. The pressure hull was dished inward by as much as 2-1/2 inches in the after battery compartment on the starboard side forward and the port side aft. The conning tower plating was depressed to a depth of about 2 inches over an area about three feet by one foot. The engine room hatch, conning tower hatch and conning tower door gaskets were crimped and leaked steadily. The inboard hull flapper valves for the ship's supply ventilation system and the engine air induction system were jammed closed. MBT No. 5 master vent valve also jammed in the closed position. The battery exhaust system outboard valve apparently opened momentarily upon one or more close detonations and sea water flooded the exhaust duct section in the control room, some of it splashing onto the fire control panel. The high pressure air bank in the after battery well commenced to leak heavily. Both main batteries showed full ground. No. 2 periscope could not be moved. No. 1 periscope could be raised and lowered but required the combined effort of four men to train it. Ninety per cent of the gauges and instruments in the engine room were broken or deranged and several depth gauges were also put out of commission. Considerable inboard leakage occurred through a cracked weld at the hull flange of the air conditioning circulating water supply system.

____________

1 A list of anti-submarine attacks, received from the Japanese at the end of the war, which were assessed as resulting in "positive" sinkings, mentions several attacks in this area on 1-2 March 1942 but no amplifying data was submitted and none can be definitely identified as having been made on PERCH.

4-8. It is interesting to note that although this first series of attacks was sufficiently severe to cause considerable permanent hull deformation, the watertight integrity of the hull proper remained substantially intact and no serious damage was sustained at this time by either the submerged propulsion plant or vital auxiliary systems and equipment. It is probable that all of the depth charges were set for detonation at 98 feet since the next deeper setting available on Japanese charges was 197 feet and the depth of the water in which the attack occurred was reported to have been only about 150 feet, a fact certainly known to the enemy.

4-9. Shortly after receiving the third depth charge pattern, PERCH got underway again and by using evasive tactics managed to lose both destroyers in about two hours. At about 0300, 2 March, PERCH surfaced and an inspection topside was made. All the radio antennae insulators were found to have been broken. An armful of fragments from the depth charge cases was picked up on deck. Both periscope head windows were shattered and both periscope tubes had completely flooded. The bridge blinker light was found compressed flat.

4-10. No. 1 main Diesel engine ran away on starting and the camshaft of No. 4 main engine was found broken, leaving only two main engines in operating condition. No. 2 main engine was put on battery charge and No. 3 main engine was put on propulsion. PERCH once again proceeded in the direction of the Japanese landing on Java, still with intentions of attacking the enemy. Repairs to damage were started where possible and the high pressure air banks were replenished.

4-11. At about 0400, approximately two hours before sunrise, the same two Japanese destroyers were again sighted. PERCH immediately submerged and lay on the bottom in about 200 feet of water with all machinery secured. This course was chosen rather than evasive running for the machinery had developed a high noise level as a result of the previous attack and it would have been necessary to use the very noisy trim pump almost constantly in order to maintain depth control.

4-12. Unfortunately, the enemy destroyers had either sighted PERCH before she submerged or had established definite sound contact, for several depth charge attacks were immediately delivered, resulting in serious damage. An attempt was then made to get under way and take evasive action but the propulsion plant was found to be inoperative, due to short circuits in the electrical control gear or damage to the main motors, and PERCH was forced to remain on the bottom. Following this series of attacks, the enemy destroyers apparently decided to postpone further efforts until daylight but in the meantime made frequent checks on PERCH's position by echo-ranging.

4-13. Shortly after sunrise, three more attacks were delivered, the final pattern of three charges at about 0830 being the most severe of all. The enemy destroyers then left the area, probably again certain that they had destroyed their target.

4-14. Reference (b) reports that "there was hardly any part of the boat that had not in some way been damaged." Only one of the four main Diesel engines was not damaged beyond immediate repair. However, the two auxiliary engines (Winton 6-241) were still operable. The port reduction gear casing was cracked and lost lubricating oil constantly. As mentioned above, the submerged propulsion plant was put out of commission due to deranged control equipment and motor damage. Numerous holding down bolts on the main motors, main generators and main engines were reported to have broken.

4-15. The pressure hull overhead in the forward battery compartment was dished inward to a depth of about 1-1/2 inches over an area of about 6 feet by 2-1/2 feet and many other new indentations occurred at various points along the length of the ship in addition to those received from the first series of attacks. In no place, however, was the pressure hull torn or ruptured.

4-16. All lighting was cut off by a close detonation but was partially restored after a short while. Many auxiliary motors were short-circuited or deranged. There were at least nineteen cracked jars in the forward battery and one in the after battery, causing loss of electrolyte and full grounds. All of the electric alarm and telephone circuits were out of commission.

4-17. One particularly close detonation forward caused the bow planes, then on 20 degrees rise angle, to partially rig in, damaging the bow plane rigging system. The holding down studs for the bow plane tilting motor backed off or elongated and the shims dropped out. The planes were thereafter tilted by hand. The radio antenna trunk flooded. The JK sound head was put out of commission. Torpedoes loaded in forward tubes Nos. 1 and 2 and one torpedo loaded in an after tube were reported to have made "hot" runs. Many torpedo tube doors were jammed. All water closet bowls (porcelain) were shattered. The engine room deck support stanchions were torn away at their overhead connection to the pressure hull.

4-18. Both Nos. 1 and 4 high pressure air banks bled completely down through numerous leaks and various other air system leaks developed throughout the boat. The increase in pressure of the atmosphere within the boat from these air leaks was considerable although it could not be measured since the barometer was broken. The excessive air pressure, extreme heat, and high humidity caused much discomfort and had a deleterious effect on all hands.

4-19. Sea water leakage into the pressure hull also increased markedly. Strips a quarter of an inch square in cross section had been cut from the conning tower and forward escape trunk door gaskets. Leakage around these doors and the conning tower and engine room access hatches became serious. The air conditioning circulating water supply hull flange crack, caused by the first series of attacks, became enlarged and the flange studs elongated or the nuts backed off, further augmenting the leakage at this point. Many

other salt water systems throughout the ship also developed leaks. Fuel tanks are reported to have leaked externally.

4-20. PERCH remained on the bottom until after sunset on the evening of 2 March. Order was restored and repairs to equipment were attempted where possible during this period. Damage to one of the main motors was isolated and battery propulsion was regained on both shafts. Bilges were kept pumped down to avoid grounding electrical machinery. The forward and after trim tanks and No. 2 auxiliary tank were pumped dry.

4-21. At about 2000 on 2 March, after approximately sixteen hours submerged, the first attempt was made to surface. The boat did not move, however, for the downward thrust of the depth charge attacks had partially embedded the hull in the soft ocean floor and many master vent valves leaked or could not be seated, rendering it impossible to blow the ballast tanks since air introduced into the tanks escaped through the risers. As an indication that the boat had been forced deep into the soft bottom, it was noted during the final severe depth charge pattern that PERCH's remaining depth gauge suddenly changed reading from 200 feet to 228 feet and then to 230 feet, although this might have been due to derangement of the gauge itself.

4-22. By closing the emergency vent valves and going alternately ahead and astern at maximum revolutions on both shafts, PERCH finally broke loose from the bottom on her third attempt. These efforts consumed a period of about one hour and all high pressure air was expended except for one partially filled bank. The enemy was not in sight upon surfacing.

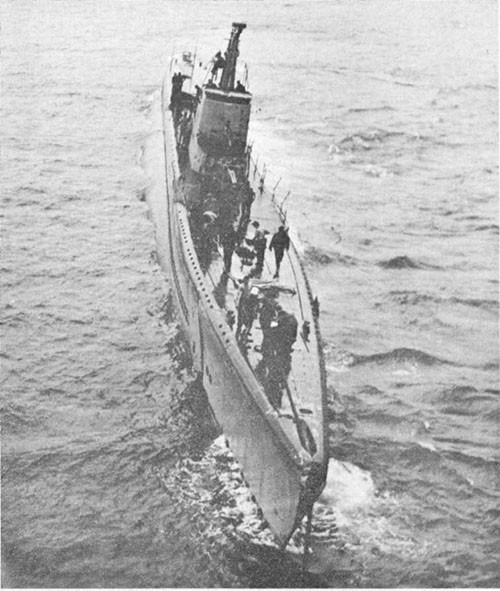

4-23. After successively attempting to start all four main engines, only No. 3 engine was found operable and PERCH got under way at a speed of about 5 knots. About half of the holding down bolts for the No. 3 engine had broken and the engine vibrated so badly that the head covers raised one inch. The batteries were put on charge with the undamaged auxiliary Diesel generators. The steering gear was behaving erratically at this time, for the rudder could be moved from the full left position only with difficulty and upon reaching amidships would suddenly snap over hard against the starboard stops. MBT No. 2 was leaking heavily from sea. Even on the surface, sea water leakage into the hull was sufficient to keep both the trim and drain pumps operating at full capacity. All gyro-repeaters had been deranged and steering was accomplished by relaying word to the bridge from a man stationed at the master gyrocompass in the control room. Many depth charge case fragments were again found on the deck topside.

4-24. After quickly surveying the condition of the boat, the Commanding Officer at this time set up procedure for scuttling the ship if it became necessary. Repairs were attempted where feasible. Men working in the engine room were unable to tolerate the extreme heat and had to be relieved frequently so they could go topside to recover.

4-25. PERCH continued to run on the surface throughout the night. In order to determine whether or not the boat could submerge, it was decided to try a running dive while still dark. This was attempted about an hour and a half before sunrise on 3 March. However, in spite of having deliberately tried to make the ship light so that trim could be established by flooding in on the dive, PERCH was found very heavy aft. The boat assumed a large up angle and water entered in large volume around the conning tower and engine room hatches which failed to seat properly. When a depth of 75 feet had been reached and the two hatches still showed no sign of seating themselves by hydrostatic pressure, the boat was surfaced. Reference (a) reports that at this time there was still only one full air bank. By the time PERCH reached the surface, the water level in the engine room bilges was almost to the main generators.

4-26. It was found that the conning tower hatch lacked complete seating by a gap of about 3/8 inch. The hatch dogs were removed and adjusted but with no improvement. This work was handicapped by the necessity of having to keep the ship darkened to avoid detection. Once again the dogs were removed, but while attempting further adjustments, three Japanese destroyers came upon the scene and opened fire on PERCH. Five or six shells landed in the water nearby.

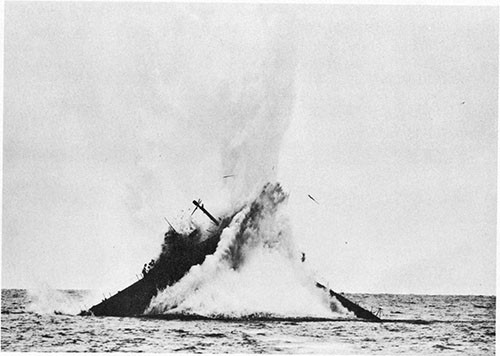

4-27. PERCH attempted to engage the enemy with her three-inch deck gun but it could neither be trained nor elevated and the sights were shattered. Torpedoes could not be fired. In this helpless condition, with no fire power, obviously unable to submerge and capable of making only 5 knots on the surface, the Commanding Officer decided to abandon and scuttle the boat at once. All hands were ordered topside. The diving alarm was sounded and the vents were opened by one officer who had remained below for this purpose. The men on deck literally felt the ship, which was still going ahead at one-third speed on her batteries, go out from under them. All the men leaving the ship were equipped with life jackets and some in addition carried escape "lungs" and flashlights. The officer who manned the vents had to fight his way out through the open conning tower hatch against the incoming water. PERCH went down about 100 yards from the survivors shortly before dawn on 3 March 1942, with her colors flying.

4-28. As far as is known, the entire crew was taken aboard by the Japanese destroyers during the morning. Most of the survivors were imprisoned until the end of the war at Makassar, Celebes, although a few were later transferred to various camps in Japan. Fifty-three officers and men are known to have survived to the end of the war.

4-29. In analyzing the many factors involved in the loss of PERCH, it appears that the conning tower and engine room hatch damage was the only reason the boat was unable to submerge upon sighting the enemy destroyers on the morning of 3 March. This case is an excellent illustration of the unhappy fact that but one casualty to a vital part of a submarine can cause its loss.

4-30. However, even had PERCH been able to submerge, it is problematical whether she could have escaped eventually. For example, the extent of external leakage from the oil tanks is not known. This alone might have been sufficient to disclose her exact location to the enemy and in such shallow waters it is likely that she would not again have survived a series of well executed depth charge attacks. Even had the destroyers not discovered PERCH on the morning of 3 March, in the event that repairs could not be made to the damaged hatches it is doubtful that she could have made a surface escape with only one engine, for the Java Sea was at this time completely controlled by the Japanese.

U.S.S. KINGFISH (SS234)

Depth Charge Damage

Off Formosa

23 March 1943

| Class | SS212 |

| Builder | U.S. Navy Yard, Portsmouth, N. H. |

| Commissioned | 20 May 1942 |

| Length (Overall) | 311 ft. 8 in. |

| Beam (Extreme) | 27 ft. 3 in. |

| Submergence Depth (Designed Maximum)(Axis) | 300 ft. |

| Displacements | |

| Standard | 1525 tons |

| Emergency Diving Trim | 2050 tons |

| Submerged | 2415 tons |

| Draft (Mean, Emergency Diving Trim) | 16 ft. 10 in. |

| Type of Propulsion | Diesel Electric Reduction Drive |

| Main Engines (4) | Fairbanks-Morse 38-D-8-1/8 |

| Main Motors (4) and Generators (4) | Elliott Co. |

References:

(a) C.O. KINGFISH conf. ltr. SS234/A12-1/A-16-3/A9 of 8 April 1943 (Report of War Patrol Number Three).

(b) Comdt. Navy Yard Mare Island conf. ltr. SS234/L11-1 (33-558674) of 17 May 1943 with enclosures thereto (Supplementary Report on KINGFISH War Damage).

(c) BuOrd (Re6) Memorandum dated 4 May 1943 (Report on Inspection of KINGFISH Damage and Interview of Ship's Officers by Dr. A. B. Focke).

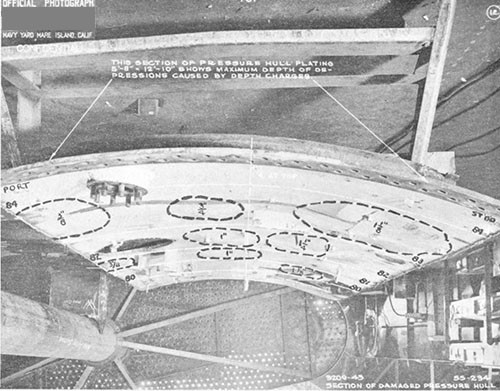

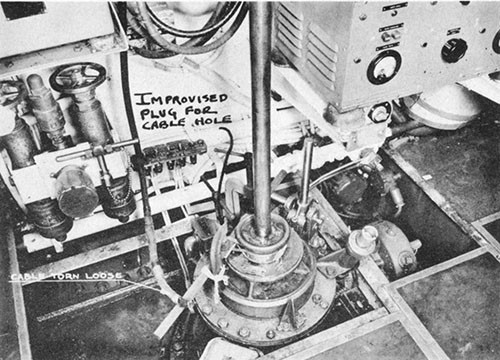

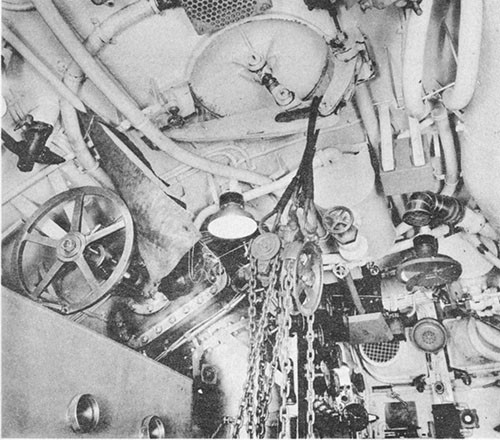

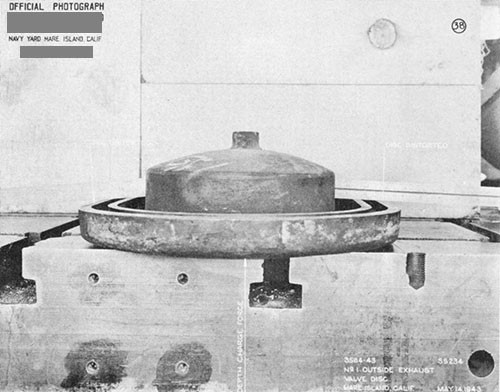

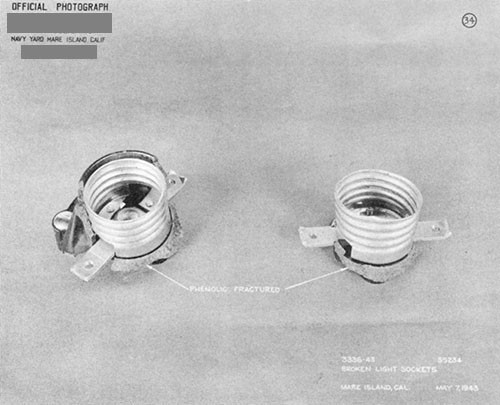

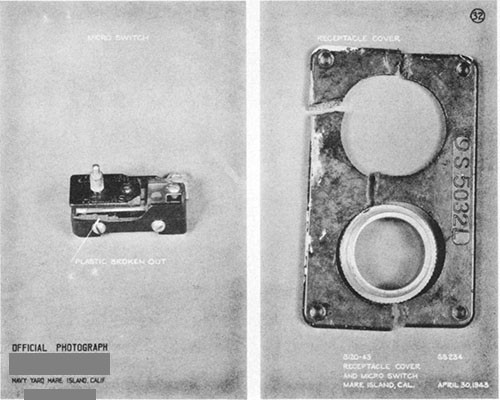

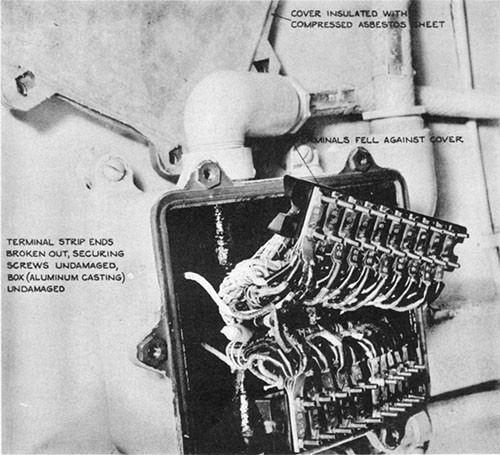

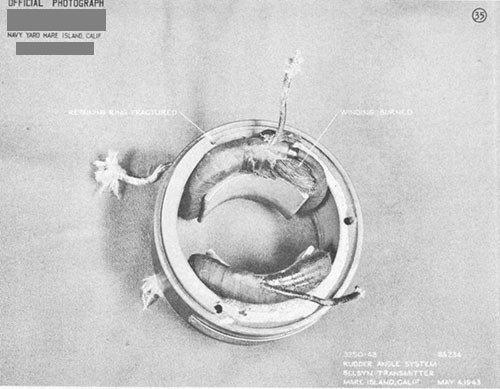

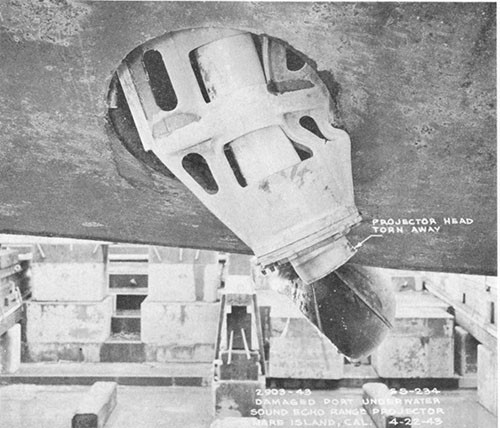

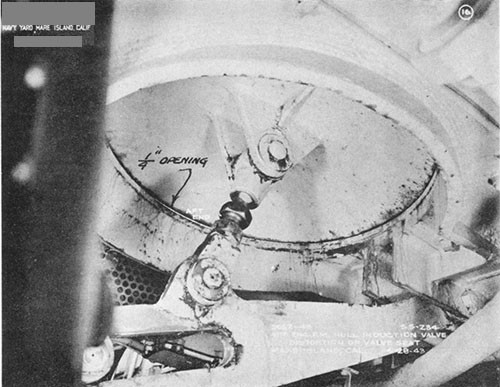

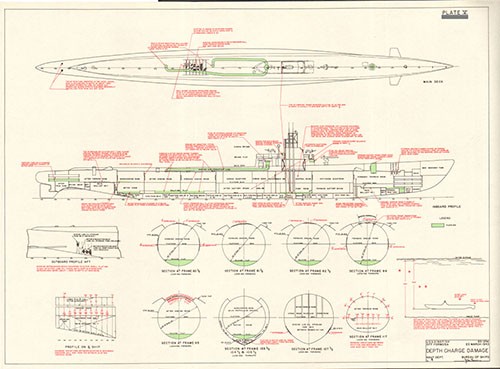

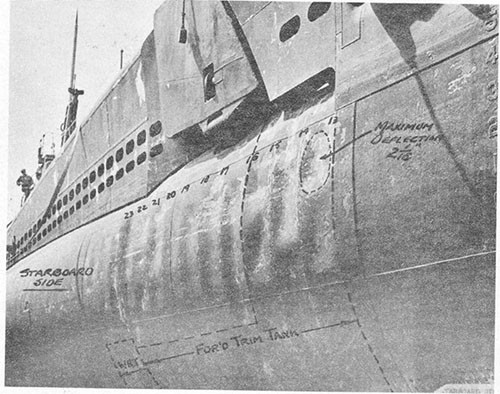

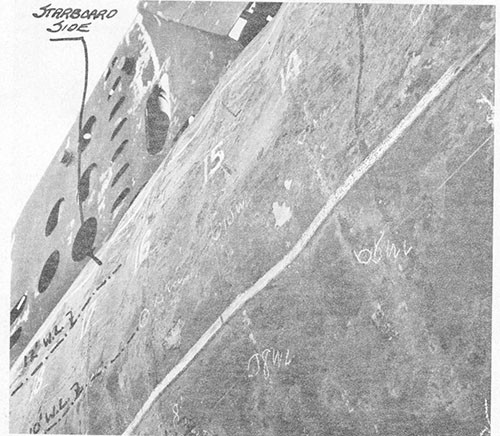

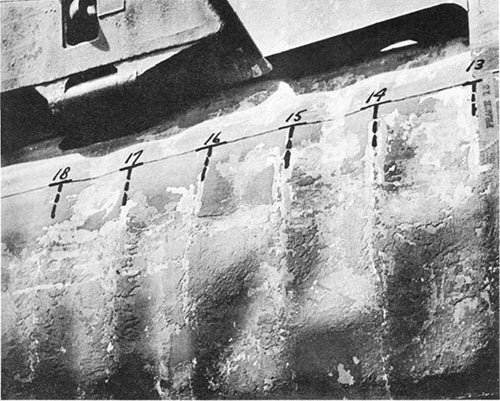

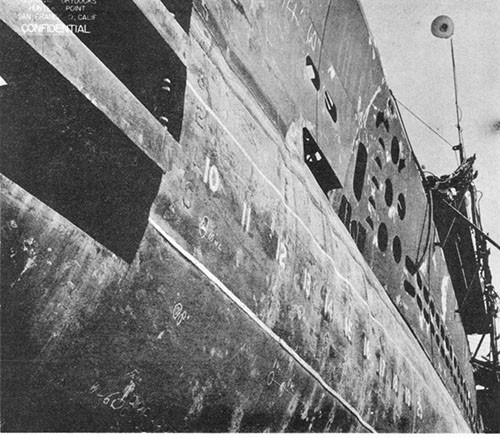

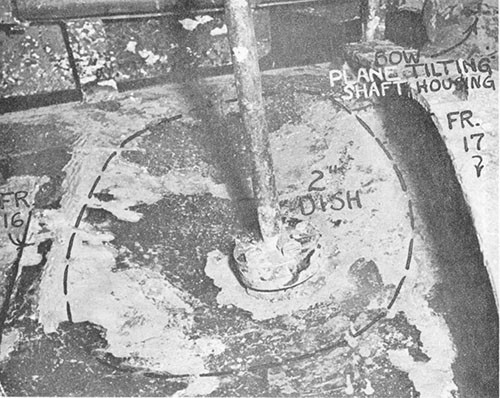

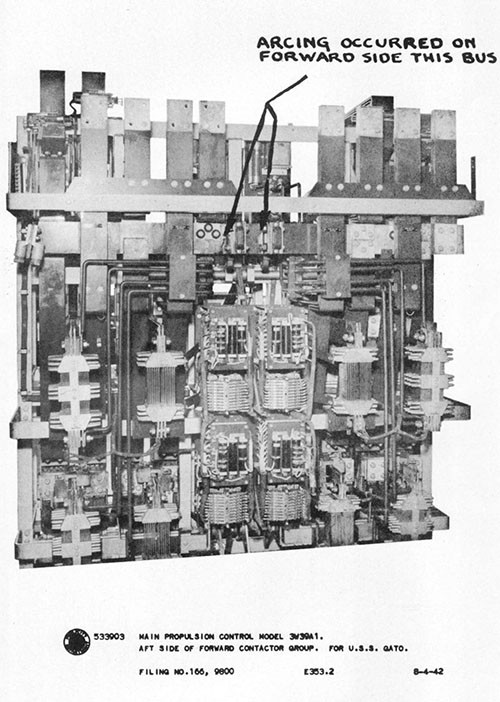

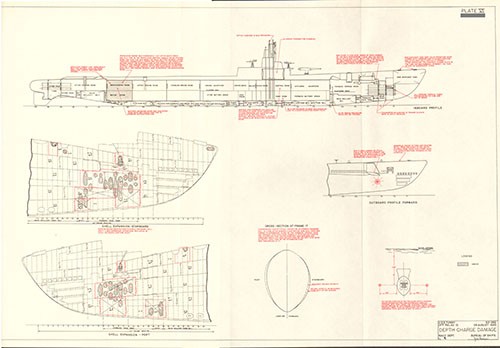

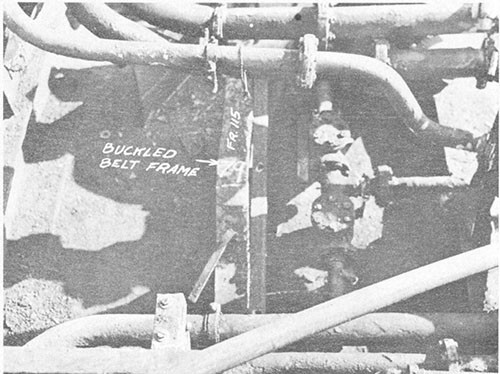

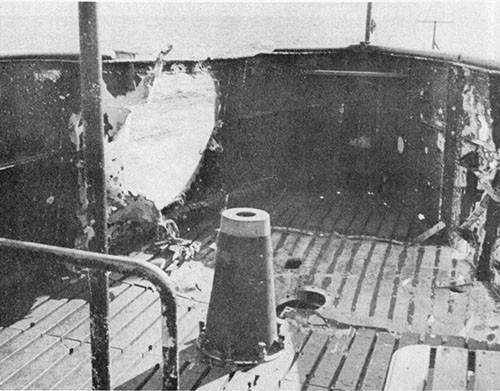

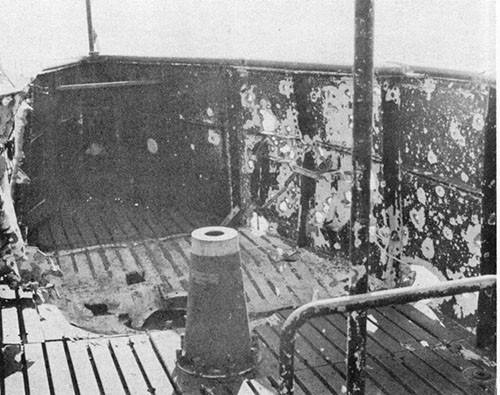

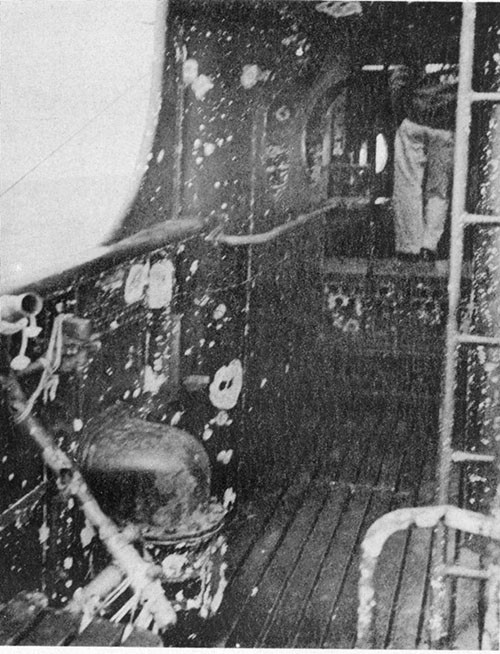

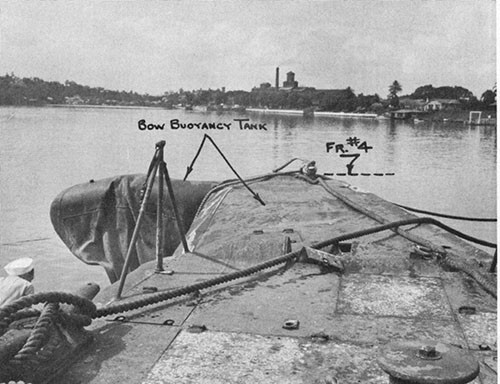

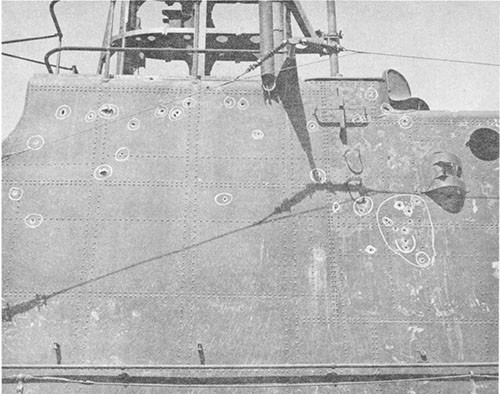

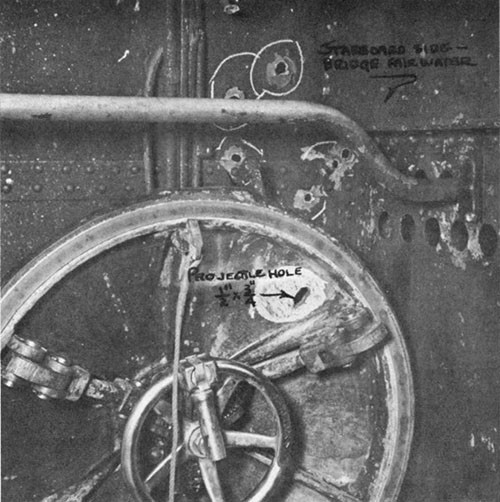

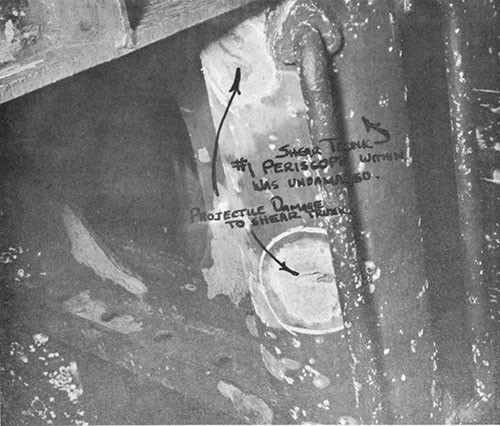

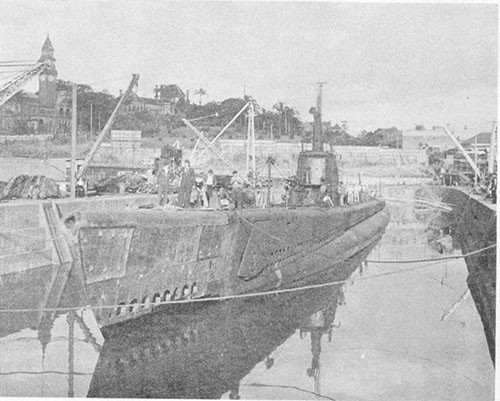

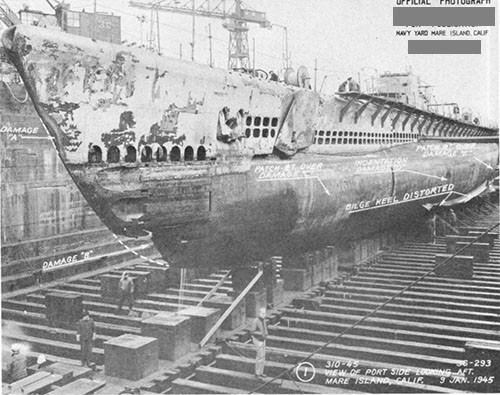

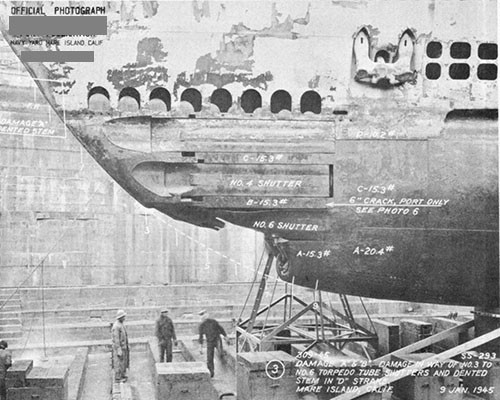

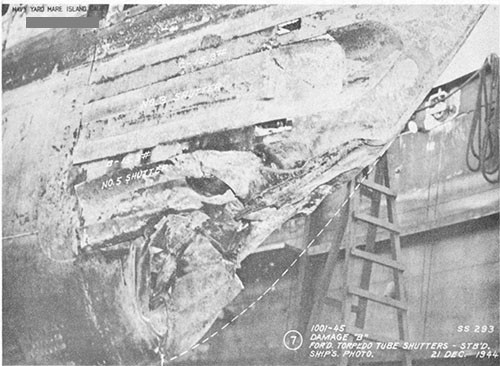

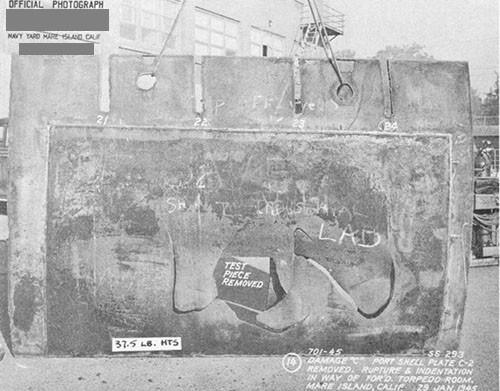

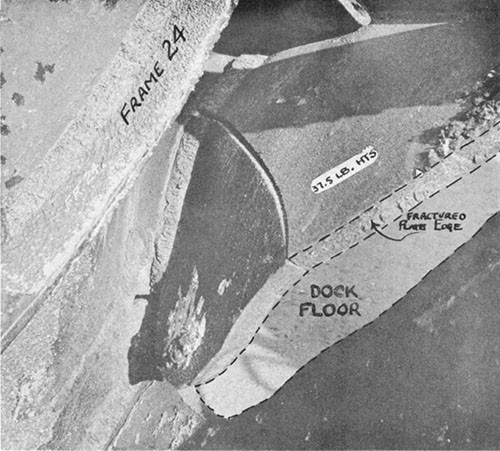

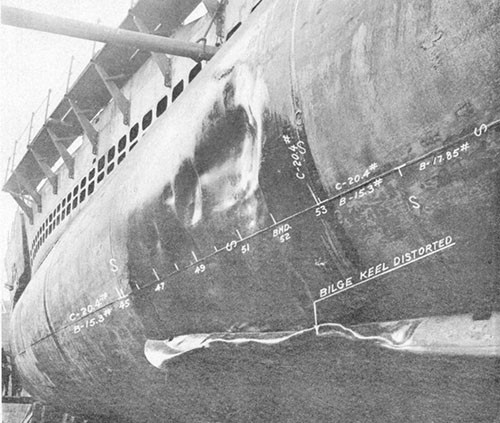

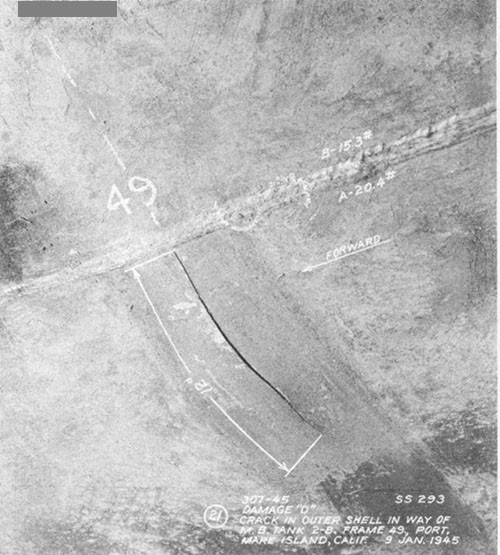

Photographs Nos. 5-1 through 5-16 (furnished by Navy Yard, Mare Island).

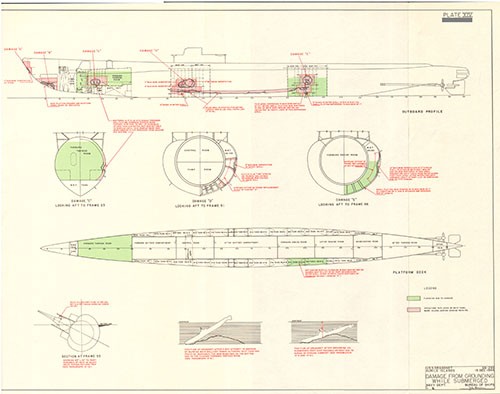

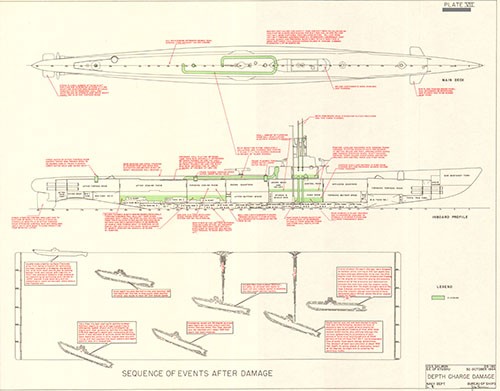

PLATE V

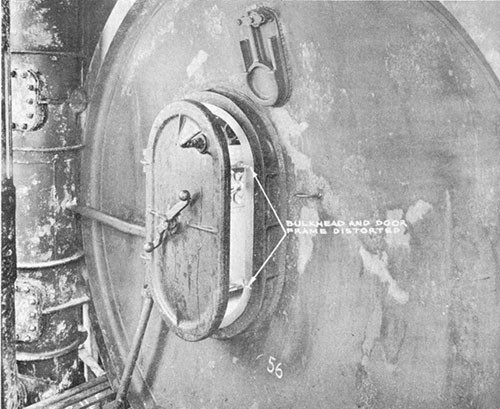

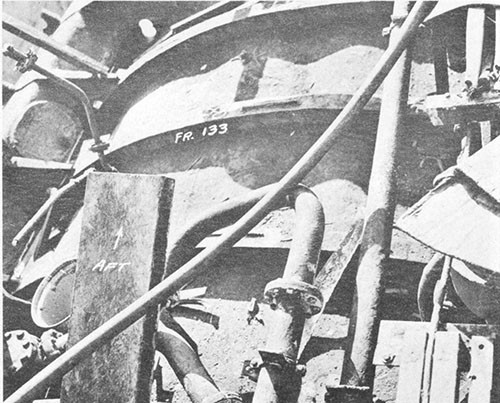

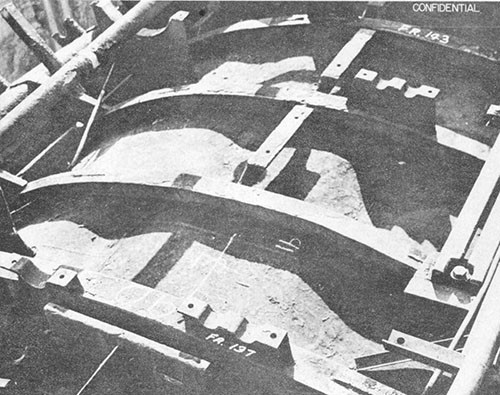

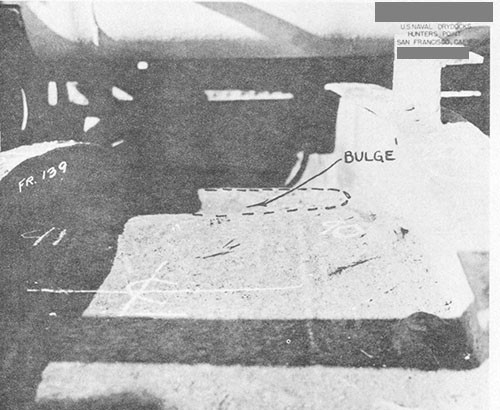

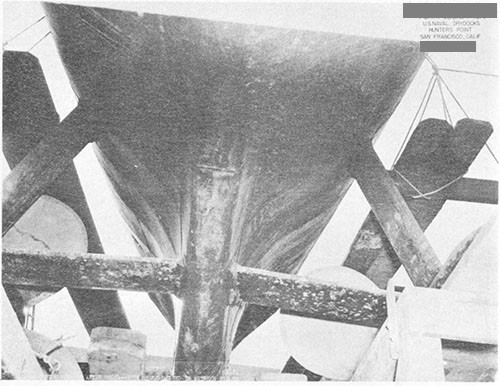

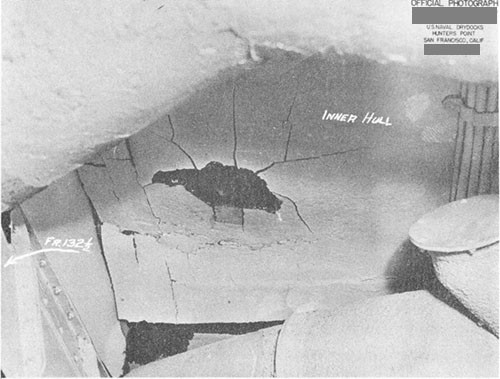

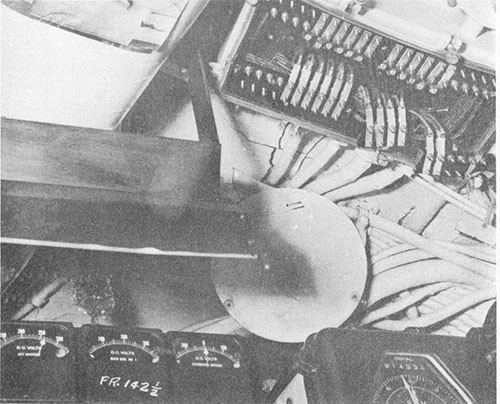

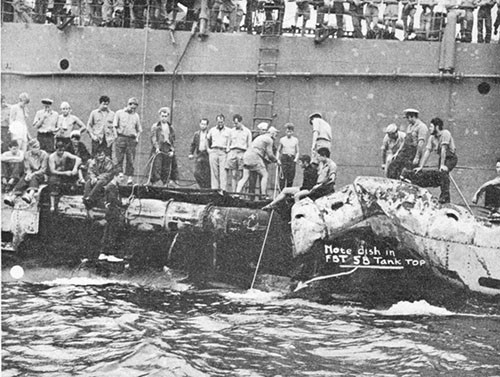

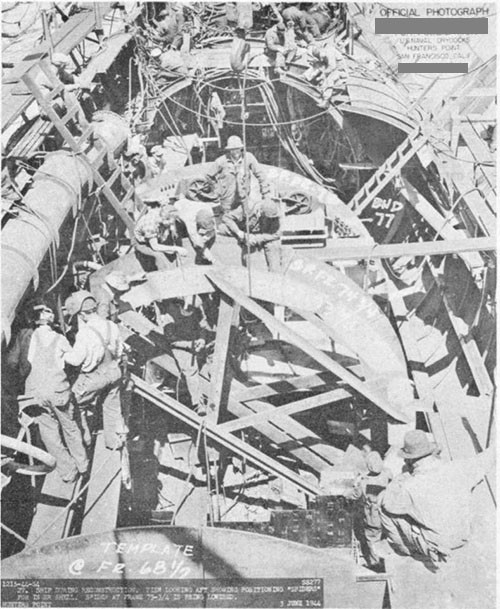

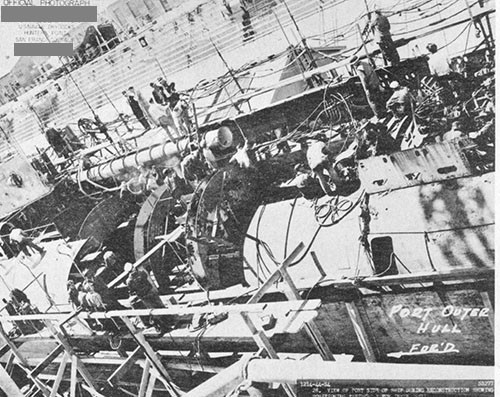

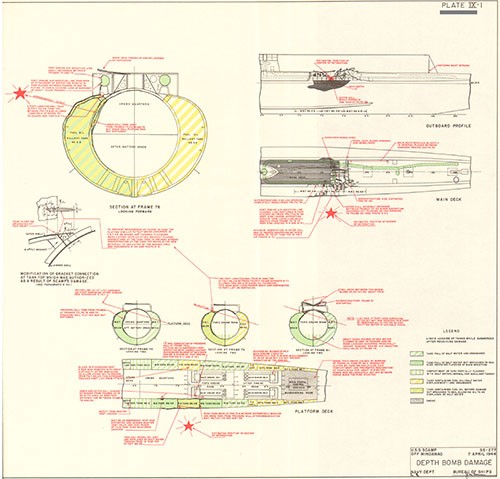

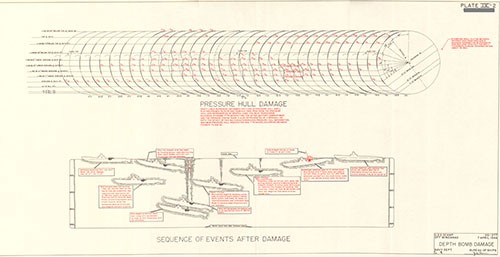

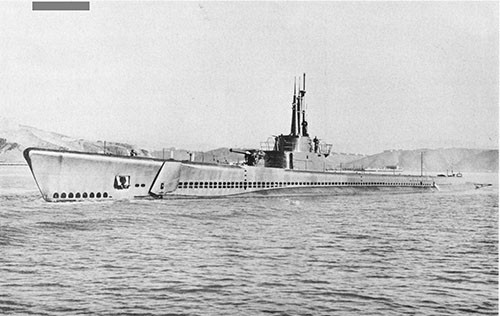

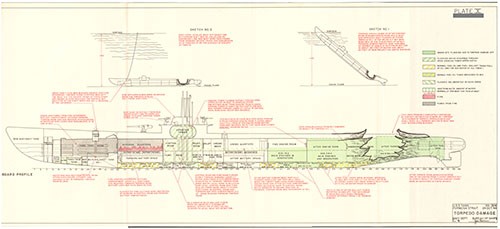

5-1. On 23 March 1943, while on her third war patrol, KINGFISH underwent a severe depth charge attack north of Formosa. A total of over forty depth charges were dropped in the vicinity of KINGFISH during the 7-1/2 hour period she was under attack. Serious damage was caused by the final pattern of six charges, two of which detonated close over the after portion of the ship while the boat was running at 300 foot depth, forcing her to the bottom in 350 feet of water. In spite of sustaining considerable permanent pressure hull deformation in various areas and widespread interior damage, no vital systems or machinery were put out of commission and watertight integrity remained substantially intact. Six hours after the termination of the attack, and without undue difficulty, KINGFISH was able to surface and clear the area at full power on all main engines. This report is based on the information contained in the references and on an informal interview with the then Commanding Officer. The Photographs were furnished by the U.S. Navy Yard, Mare Island. The PLATE was prepared by the Bureau from data contained in the enclosures to reference (b).

5-2. KINGFISH arrived at Pearl Harbor from her second war patrol on 23 January 1943. Normal refit was undertaken by repair forces of the Submarine Base, Pearl Harbor, and completed on 7 February. Deperming, sound tests and training were completed on 15 February and, on 16 February, KINGFISH departed Pearl Harbor for Midway, arriving on 20 February. Minor voyage repairs were made there and fuel and lubricating oil were topped off. She departed Midway on 21 February for her third war patrol and arrived on station in the wafers adjacent to the Island of Formosa on 7 March, destroying a 250-ton enemy trawler by three-inch gunfire attack on 4 March while en route. On 17 March KINGFISH sank a medium-sized freighter by two torpedo hits during a night submerged periscope attack and on 19 March sank a medium-sized troop transport by two torpedo hits during a daylight submerged periscope attack. Three other attacks were made but no hits were obtained, apparently due to faulty torpedo performance.

5-3. At 0300 on 23 March, while surfaced about 60 miles north of Formosa, lat. 26° 20' N., long. 121° 55' E., KINGFISH sighted at a range of approximately 5000 yards what appeared to be either a small Japanese destroyer or minelayer of about 1200 tons. Battle stations were manned at once and an attempt was made to gain a position ahead of the enemy ship for a dawn attack. However, at 0325, the target ship detected KINGFISH and headed toward her at a speed of about 16 knots. KINGFISH was able to draw away slowly at flank speed but twenty minutes later, at 0345, the enemy illuminated her with a searchlight. At this point, KINGFISH submerged to a depth of 250 feet, rigged ship for depth charge attack and silent running, and commenced evasive action.

5-4. These maneuvers were unsuccessful, however, for at 0448 KINGFISH received the first of a long series of depth charge attacks.1

____________

1 A list of anti-submarine attacks received from the Japanese at the end of the war, and assessed as resulting in "positive" sinkings, contains no mention of this series of attacks on KINGFISH.

Evasive tactics were continued at a depth of 300 feet but the enemy was both tenacious and experienced, and seemed to have no difficulty maintaining contact. He appeared to use sonic listening for determination of azimuth and echo-ranging for distance. Sound conditions were excellent. Three attempts were made by KINGFISH to approach the surface and fire circular run torpedo shots, but each time the enemy counterattacked before a depth of 100 feet was reached and this plan had to be abandoned. At 0752 the screws of a second ship were heard. This vessel took no direct action, apparently having no depth charges, and used no sound gear other than a fathometer. A total of 41 depth charges in eight separate patterns were dropped during the entire 7-1/2 hour period KINGFISH was under attack. Attacks were spaced at about one hour intervals and consisted of from 3 to 8 charges each.

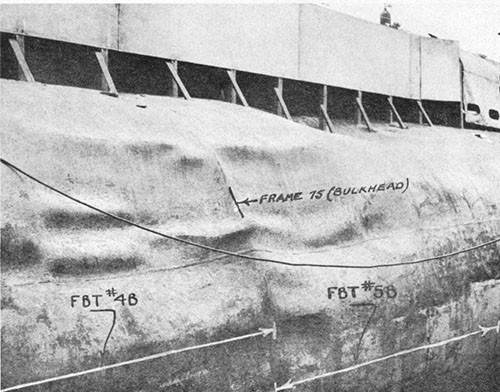

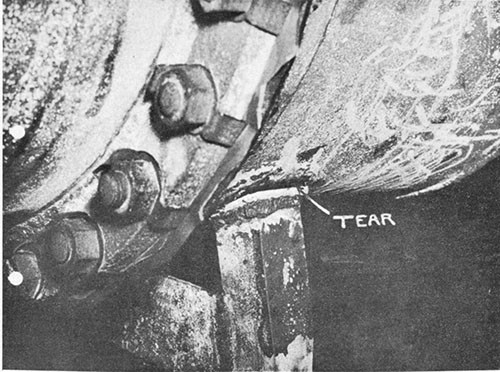

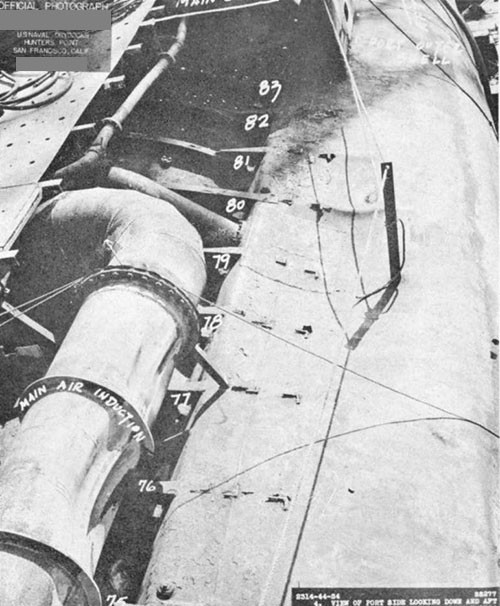

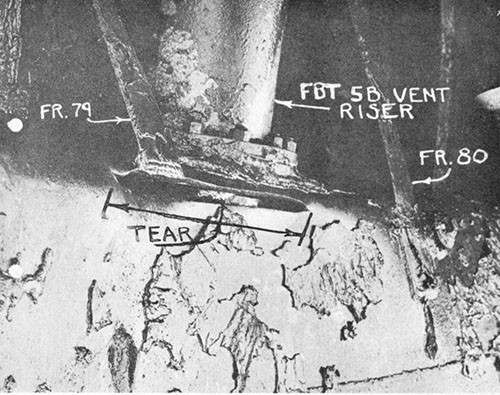

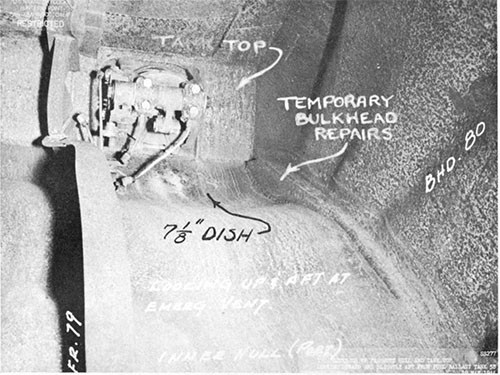

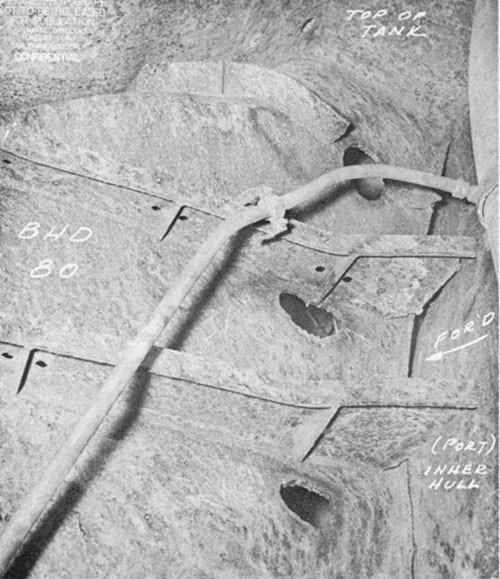

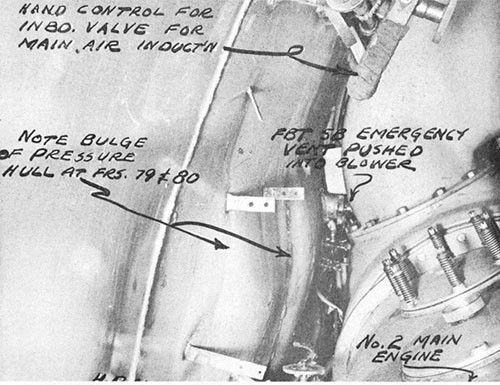

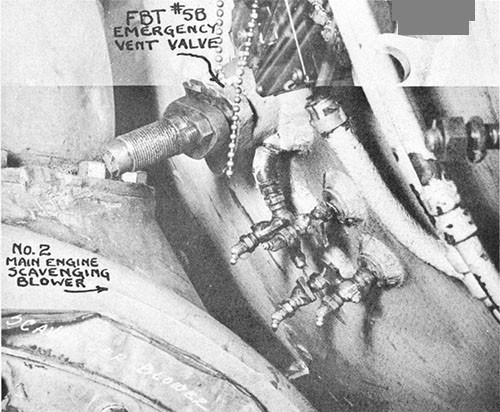

5-5. No serious damage was sustained until the final attack at 1227, at which time a pattern of six depth charges was received very close aboard while the ship was running at 300 foot depth. The charges were dropped in pairs, the first two detonating over the after portion of the ship, dishing in the pressure hull and forcing KINGFISH to the bottom in about 350 feet of water. The second pair of charges detonated forward of and above the ship, causing but little damage. The third pair of charges was delayed nearly a minute and detonated forward, also causing only minor damage. Following this attack the enemy vessels stayed in the vicinity for several more hours, occasionally making transits across KINGFISH, but did not drop any additional charges.

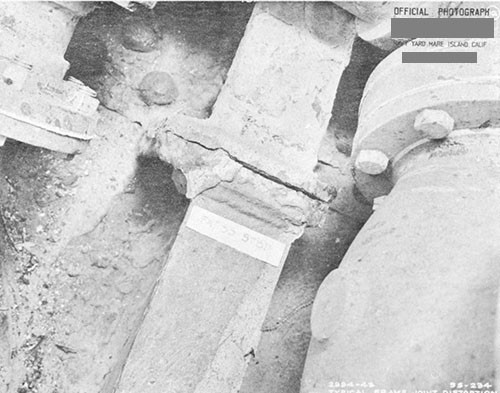

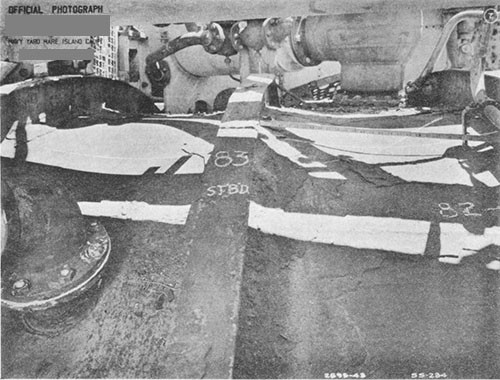

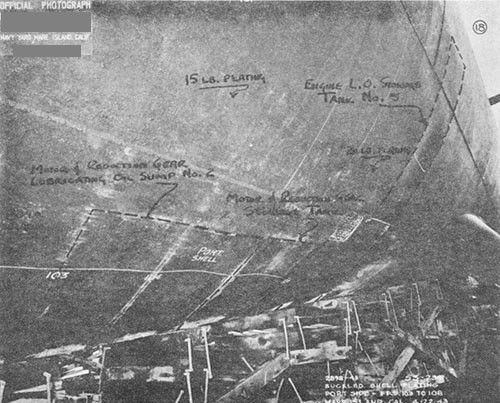

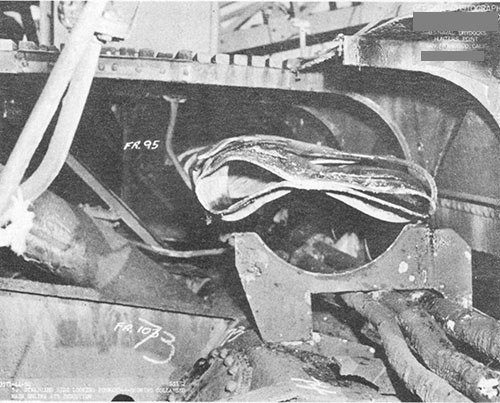

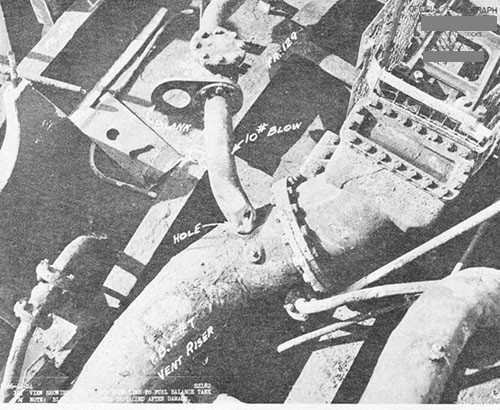

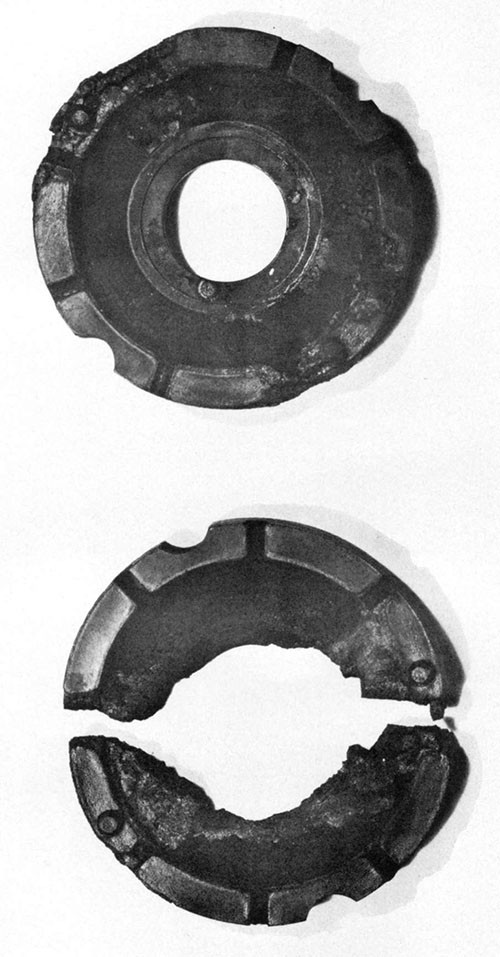

5-6. The two close detonations aft, at 1227, caused severe vertical flexural vibrations of the hull as a whole. Reference (a) reports that the ship "humped like a measuring worm" and was forced considerably off her course. Reference (c) notes that there were "three strong up and down vibrations, followed by gradually decreasing ones". This type of vibration had not been observed during any previous depth charge attacks experienced by KINGFISH. The motions were of such magnitude as to throw two men from their bunks to the deck and other personnel lost their footing even though braced in anticipation of shock. Some 12 of the 41 charges dropped on KINGFISH were close enough to cause at least minor damage. The more distant of these 12 charges broke lights, stopped clocks, jarred cork insulation from the hull and, in general, caused lightly attached hull fittings to come loose. Closer-in charges caused numerous hull valves throughout the boat to open. Two observers claimed to have seen flame shoot past the breech door of one of the after torpedo tubes coincident with the detonations of the two very close depth charges aft. Smoke and fumes were also detected in the after torpedo room.1

5-7. All of the depth charges dropped by the enemy were probably of the Type 2, Mod. 1 design containing 357 pounds of Type 98 explosive. The two close detonations aft at 1227, which were responsible for most of the damage, are believed to have been centered as follows: One charge at the after end of the ship about ten feet above the deck level, causing the phenomena observed at the torpedo tube and forcing the

____________

1 For further discussion, see paragraphs 15-18, 15-19 and 15-20.

stern down with resultant plating failure under compression at the lower outer hull between frames 103 and 108; the second charge approximately 40 feet directly above the hull at about frame 83, causing the pressure hull structural deformation which occurred in way of the forward engine room.